- Product Details

- {{item.text}}

Quick Details

-

delivery time:

-

20 days

-

payment terms:

-

T/T, L/C

-

aftersales:

-

installation, trainning and skill instruction

-

Tank size:

-

2500*3150

-

Volume:

-

13.14 cubic meter

-

Impeller diameter:

-

935mm

-

Impeller speed:

-

52r/min

Quick Details

-

Place of Origin:

-

China

-

Name:

-

Double Impeller gold leaching tank with agitator

-

business type:

-

manufacturer plant

-

delivery time:

-

20 days

-

payment terms:

-

T/T, L/C

-

aftersales:

-

installation, trainning and skill instruction

-

Tank size:

-

2500*3150

-

Volume:

-

13.14 cubic meter

-

Impeller diameter:

-

935mm

-

Impeller speed:

-

52r/min

Product Application of Double Impeller gold leaching tank with agitator

Gold ore leaching tank features of reasonable and compact structure, high transmission efficiency.

Gold ore leaching tank adopts two new type bigger impellers, low rotational speed,less power consumption, inside hollow shaft can suck the air into the tank,and improve the leaching environment. Gold ore leaching tank is widely used in gold and silver ore dressing plant for cyaniding treatment, CIP process, and carbon-in-leach work.

Main feature of

Double Impeller gold leaching tank with agitator

1.Smooth movement, pulp mixing, less power consumption.

2.air after driving hollow shaft into the groove, and the blade agitation, air dispersion evenly.

3, compact structure, convenient maintenance.

4, to the bottom of the hollow shaft ventilation, air through it into the slot, uniform dispersion, small air bubbles.

5, the two new type of impeller, the impeller diameter, low speed, small power consumption, can reduce carbon wear.

6, stirring intensity, moderate groove pulp density, fineness distribution is consistent, can improve the rate of pass in and out of cyanide and charcoal adsorption rate.

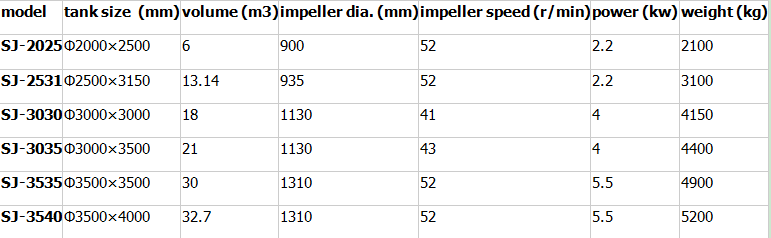

Technical Parameters of Double Impeller gold leaching tank with agitator

Gongyi Hengchang Metallurgy Building Material Equipments plant was built in 1992, is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments. The products are widely used in mineral processing, metallurgy, building materials, chemicals, electricity, petroleum, coal, transportation, fertilizer , gas industry etc.