- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Twist tie machine

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

10m*2m*2m

-

Power (kW):

-

40

-

Weight:

-

5000 KG

-

Raw material:

-

PE+steel wire

-

Inverter:

-

ABB

-

Automatic Grade:

-

Automatic

-

Certification:

-

CE

-

Power:

-

40kw

-

Marketing Type:

-

Hot Product 2023

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

25:1

-

Screw diameter (mm):

-

45

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Twist tie machine

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

10m*2m*2m

-

Power (kW):

-

40

-

Weight:

-

5000 KG

-

Raw material:

-

PE+steel wire

-

Inverter:

-

ABB

-

Automatic Grade:

-

Automatic

-

Certification:

-

CE

-

Power:

-

40kw

-

Marketing Type:

-

Hot Product 2023

Plastic twist tie extrusion machine

1. About Twist Tie

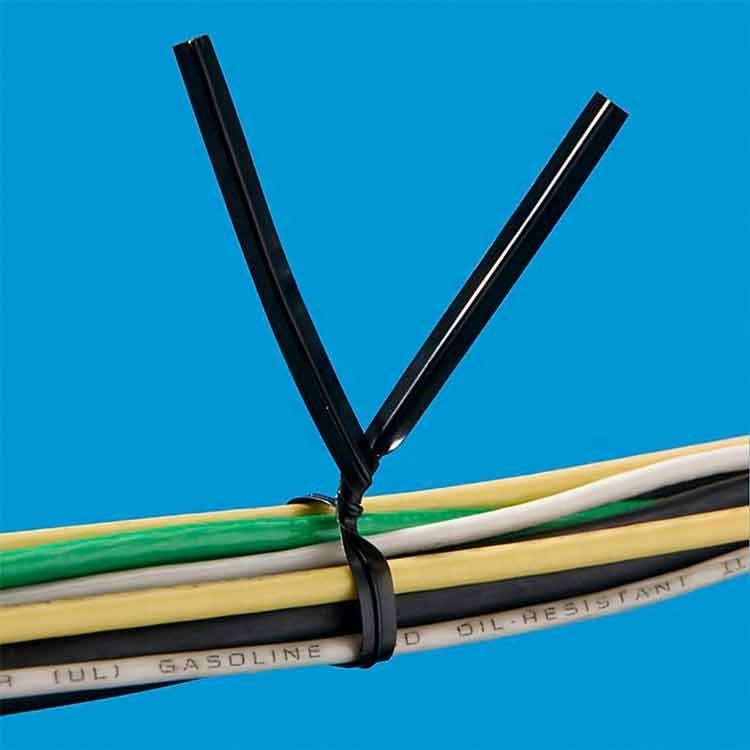

A twist tie is a metal wire that is encased in a thin strip of paper or plastic and is used to tie the openings of bags, such as garbage bags or bread bags . It is also called garden twist wire . A twist tie is used by wrapping it around the item to be fastened, then twisting the ends together (thus the name). They are often included with boxes of plastic food bags or trash bags , and are commonly available individually in pre-cut lengths, on large spools, or in perforated sheets called gangs.

The outer covering can be in a variety of colors with or without printing. Plain paper, metallic paper, plastic, poly, or custom coatings are popular for different applications. The plastic, poly, or metallic paper twist ties withstand water better than the uncoated paper versions. Different sizes and strengths are used for different applications, from a small closure for a bag of bread to a large, heavy tie to hold unwieldy garden hoses in place. A twist tie with a broad paper covering may also be used for labeling.

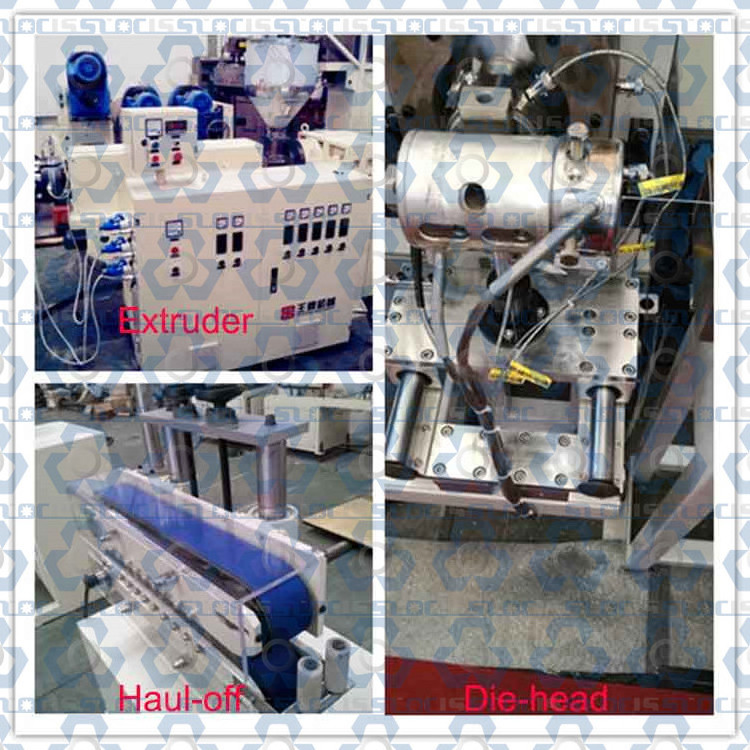

2. Technical process

Wire pay-off

⇓

Extruder⇒ Extrusion head⇒ Cooling tank ⇒ Haul off⇒ Winder

3. Technical configuration

| Item. | Equipment Name | Model |

| 1.1 | Automatic loader | JLD30 |

| 1.2 | Hopper dryer | GZ104 |

| 1.3 | Wire unwinding machine | CS-1 |

| 2.1 | PE/PP single screw extruder | BDSJ-30/28 |

| 2.2 | Volumetric type tube die | GM-30T |

| 3 | Cooling tank | VCW-220 |

| 4 | Synchronous strap puller | QYP-400 |

| 5 | Single-position winding machine | SJQ-1000D |

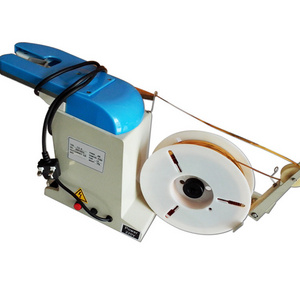

4. Machine picture