- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ROSEWOOL

-

Model Number:

-

1260, 1430

-

Application:

-

Heat Insulation, Refractory & Heat Insulation & Sealing

-

Dimensions:

-

Customer Requestion

-

Working Temperature:

-

1050℃--1350℃

-

Fiber Diameter:

-

3-5um

-

Thermal Conductivity:

-

0.075

-

Shrinkage (1800℉, 3h):

-

3%(24 hours)

-

Product name:

-

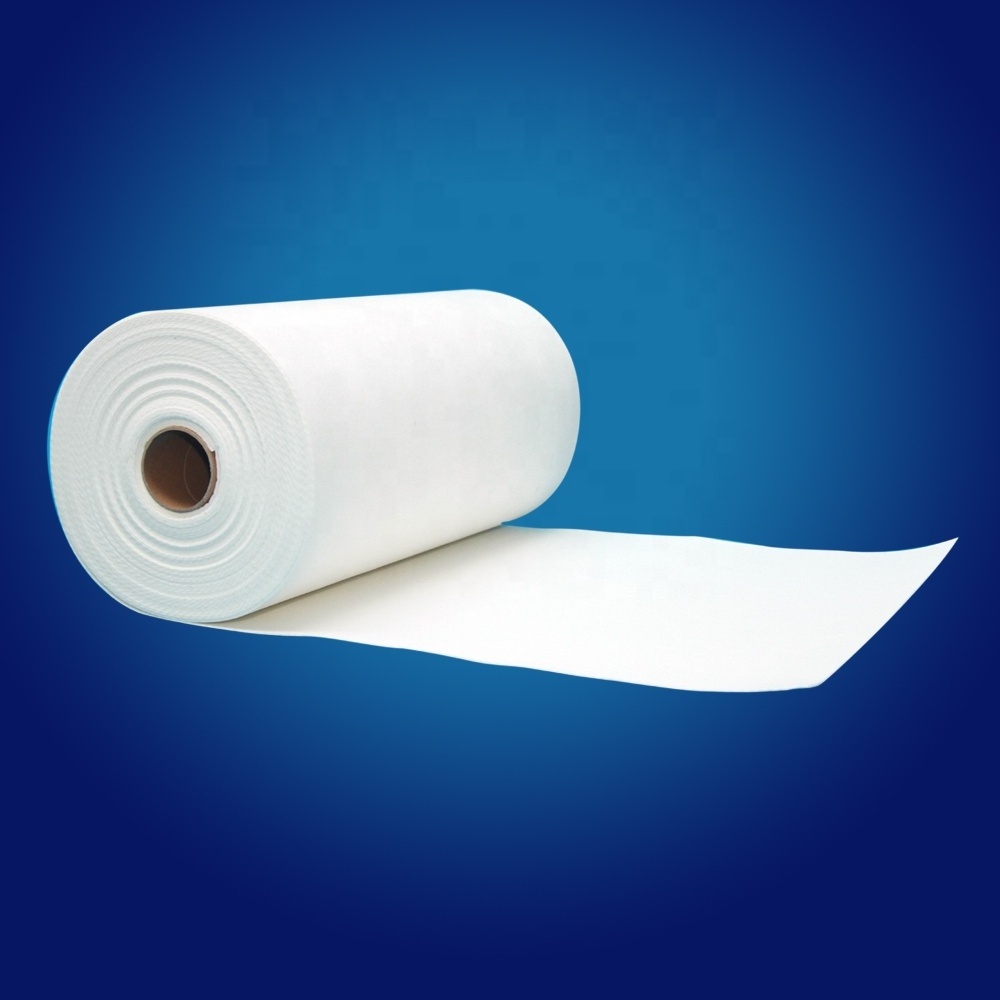

Ceramic Fiber Paper

-

Certificate:

-

CE ISO

-

Color:

-

White

-

Material:

-

High Alumina wool

-

Classification temperature:

-

1050℃/1260℃/1350℃/1430℃/1600℃

-

SIZE:

-

0.5-6mm

-

Character 1:

-

low thermal conductivity

-

Character 2:

-

heat insulation

-

Density:

-

200-250 kg/m3

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.5

-

Density (kg/m³ ):

-

180 kg/m3-220 kg/m3

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ROSEWOOL

-

Model Number:

-

1260, 1430

-

Application:

-

Heat Insulation, Refractory & Heat Insulation & Sealing

-

Dimensions:

-

Customer Requestion

-

Working Temperature:

-

1050℃--1350℃

-

Fiber Diameter:

-

3-5um

-

Thermal Conductivity:

-

0.075

-

Shrinkage (1800℉, 3h):

-

3%(24 hours)

-

Product name:

-

Ceramic Fiber Paper

-

Certificate:

-

CE ISO

-

Color:

-

White

-

Material:

-

High Alumina wool

-

Classification temperature:

-

1050℃/1260℃/1350℃/1430℃/1600℃

-

SIZE:

-

0.5-6mm

-

Character 1:

-

low thermal conductivity

-

Character 2:

-

heat insulation

-

Density:

-

200-250 kg/m3

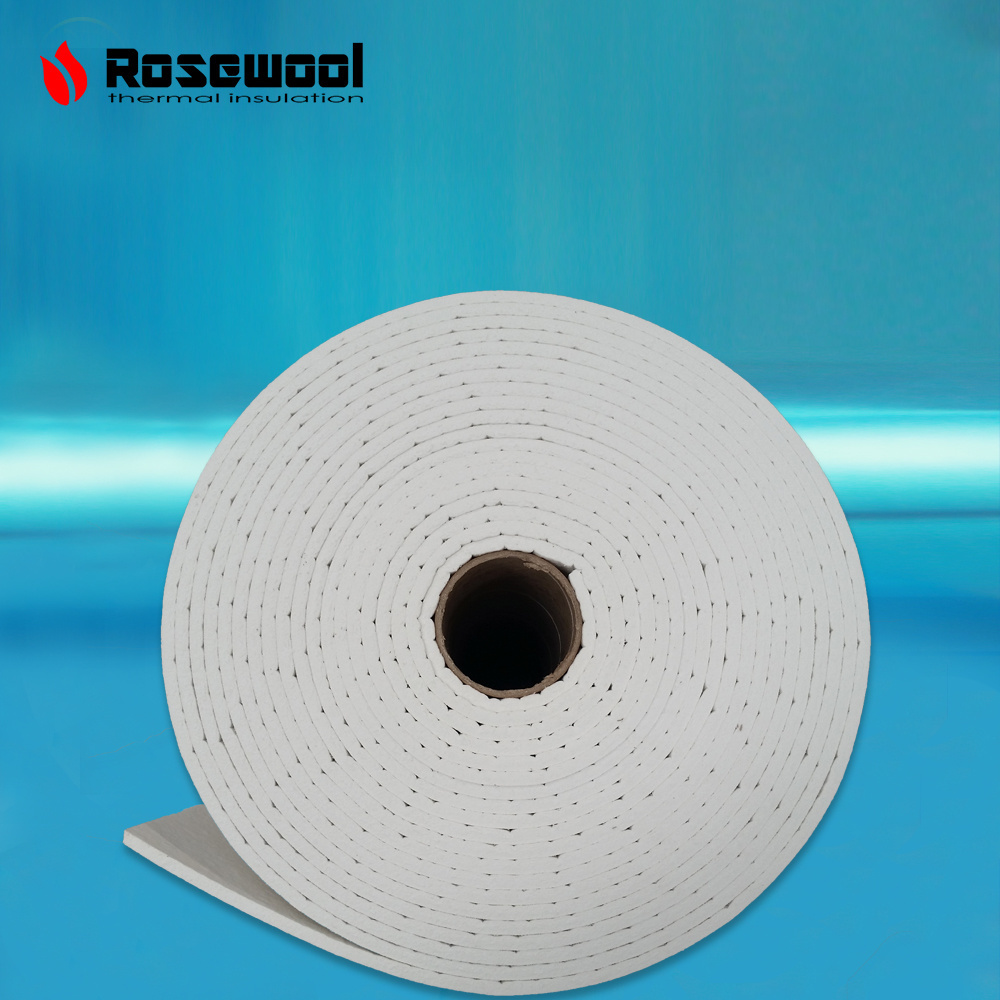

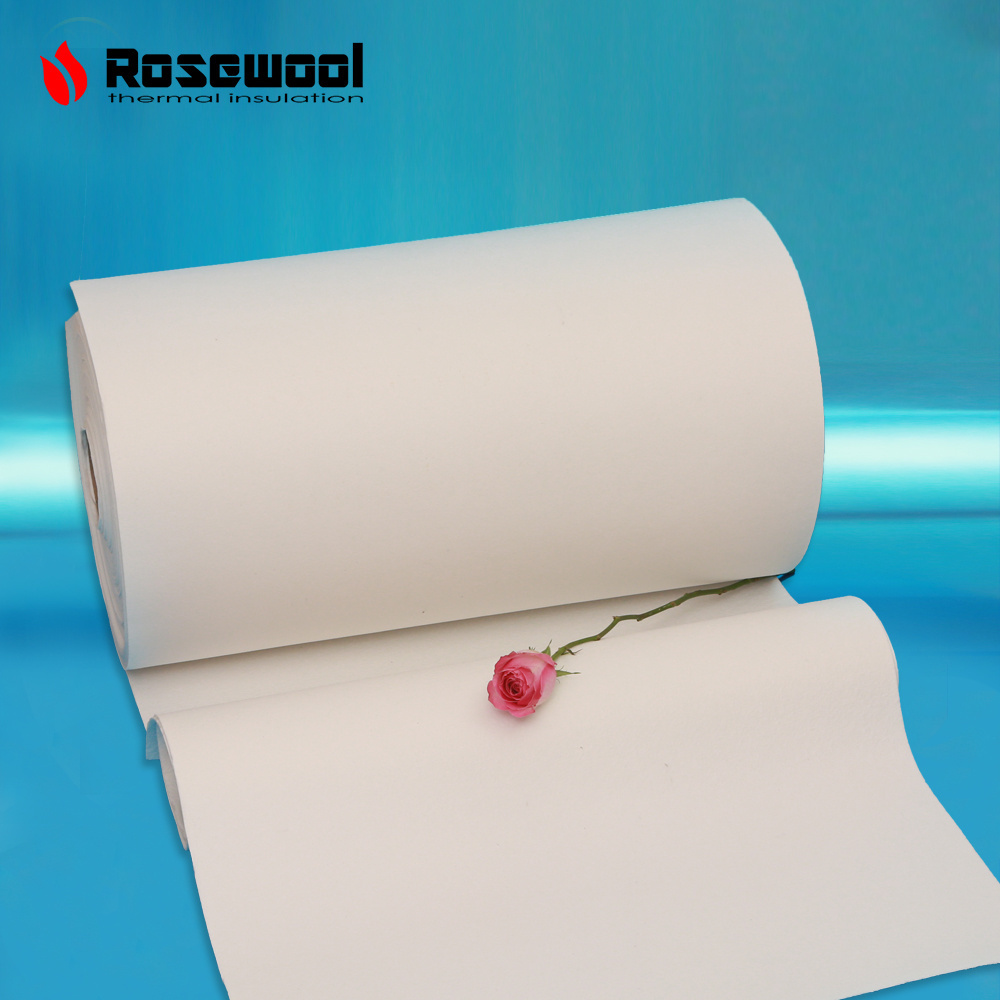

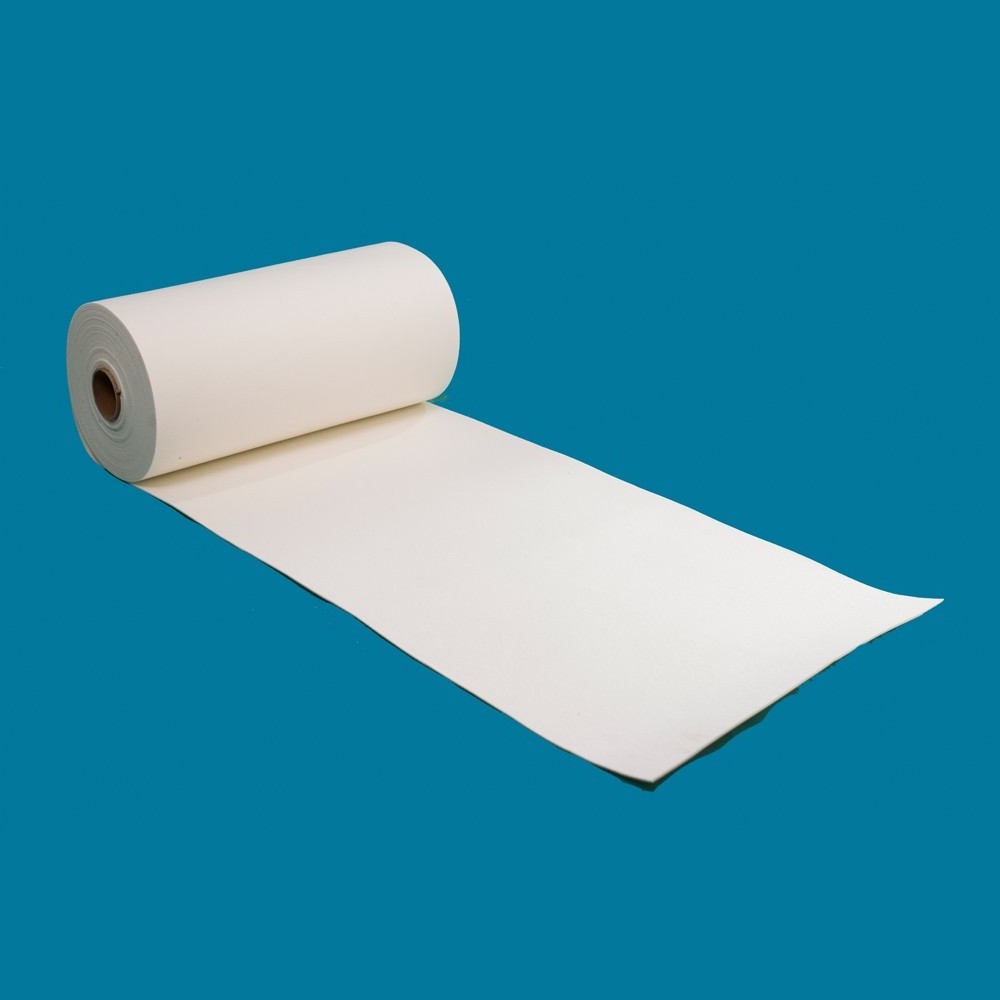

Ceramic Fiber Paper Introduction:

Density: 200-250 kg/m³ (13-16 lb/ft³)

Raw materials: Ceramic Fiber Bulk

Thickness: 0.5-6 mm

Asbestos: 100% Non Asbestos

Function: Refractory & Heat Insulation & Sealing

Blending with high quality ceramic fibers and binders, additives, ROSEWOOL ceramic fiber paper is proved to be a flexible and uniform sheet in handing heat treatment. Our paper has a highly uniform structure due to its well-controlled weight and thickness, assuring homogeneous thermal conductivity and a clean,smooth surface.

Ceramic Fiber Paper Technical Data:

| Classification Temperature |

1260℃

(2300℉) |

1430℃

(2600℉) |

|

| Bulk density (kg/m3) |

200-250

(13-16 lb/ft3) |

||

| Organic content(%) | 6-8 | ||

| Thermal conductivity(w/m.k) | 0.075-0.085 (200℃ /392℉) | ||

| 0.115-0.121 (400℃/752℉) | |||

| 0.165-0.175 (600℃/1112℉) | |||

| Moisture Content(%) | ≤1 | ≤2 | |

|

Chemical composition

(%) |

Al 2 O 3 | 45-46 | 38-47 |

| SiO 2 | 51-52 | 51-52 | |

| ZrO 2 | 15-17 | ||

| Size(mm) | 100000*610/1220*0.5(24′/48′ width) | ||

| 60000*610/1220*1(24′/48′ width) | |||

| 30000*610/1220*2(24′/48′ width) | |||

| 20000*610/1220*3(24′/48′ width) | |||

| 15000*610/1220*4(24′/48′ width) | |||

| 12000*610/1220*5(24′/48′ width) | |||

| 10000*610/1220*6(24′/48′ width) | |||

| Packing | By Carton with plastic bag | ||

Ceramic Fiber Paper Application:

1. Asbestos paper replacement

2. Investment cast mold wrap insulation

3. One-time consumable insulating applications

4. Back-up lining for metal troughs

5. Hot top lining

6. Applications where low binder content is required

7. Thermal and electrical insulation

8. Upgrade for fiber glass paper and blanket products

Ceramic Fiber Paper Features :

1. Easy to cut, wrap or form

2. Low thermal conductivity and heat storage

3. Excellent thermal shock and flame resistance

4. Light weight

5. Resilient

6. Excellent hydrophobic property

7. Good dielectric strength

8. Free of asbestos