- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

GN

-

Model Number:

-

CX-GWMP

-

Place of Origin:

-

Shanghai, China

-

Power:

-

400W

-

motor:

-

220VAC

-

Product name:

-

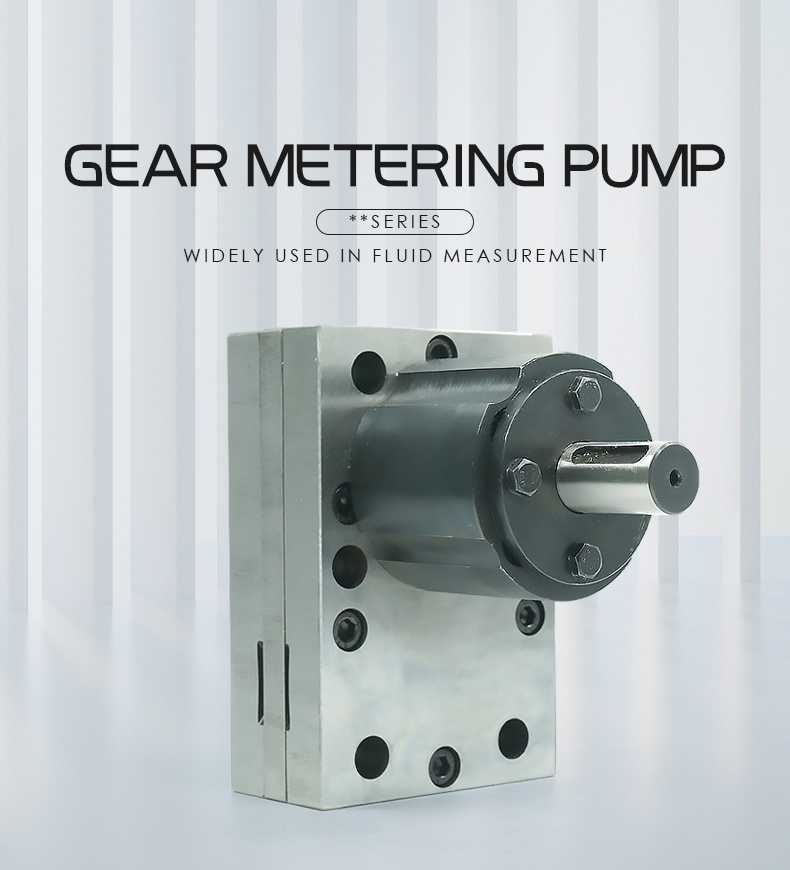

High Viscosity Gear Metering Pump

-

Material:

-

Stainless Steel

-

Keywords:

-

Liquid Transfer Pump

-

Feature:

-

Low Noise

-

Motor:

-

100% Copper Wire

-

Name:

-

Gear Pump Set

-

Function:

-

High Effeciency

-

Pump Type:

-

Electric Solenoid Metering Pump

-

Medium:

-

Chemical Fluid

-

Flow rate:

-

2-1100m /h

Quick Details

-

Application:

-

Drinking water treatment, Food and Beverage Industry, Industrial Utilities, Wastewater Transport and Flood Control, wastewater treatment, Water Distribution, Water Treatment Solutions

-

Pressure:

-

Low Pressure

-

Voltage:

-

220V

-

Brand Name:

-

GN

-

Model Number:

-

CX-GWMP

-

Place of Origin:

-

Shanghai, China

-

Power:

-

400W

-

motor:

-

220VAC

-

Product name:

-

High Viscosity Gear Metering Pump

-

Material:

-

Stainless Steel

-

Keywords:

-

Liquid Transfer Pump

-

Feature:

-

Low Noise

-

Motor:

-

100% Copper Wire

-

Name:

-

Gear Pump Set

-

Function:

-

High Effeciency

-

Pump Type:

-

Electric Solenoid Metering Pump

-

Medium:

-

Chemical Fluid

-

Flow rate:

-

2-1100m /h

Products Description

The design utilizes high standard external spur gears enclosed within a close tolerance housing assembly. This provides you the precise volume of fluid dispensed per shaft revolution. The housing is constructed from a precision ground and lapped three-plate assembly. This assembly is aligned with dowels to allow close control of operating clearances. This construction method in combination with several proprietary internal features is what ensures precise, pulseless and reliable flow under varying process conditions. When CIXI Instrument pumps are coupled with a pre-packaged, integrated, closed-loop speed control and a compact motor driver assembly (AC or DC), CIXI Instrument is able to provide the most precise and flexible metering gear pump system on the market.

|

Product Name

|

High Viscosity Glue Liquid Honey Flow Level Sensor Digital Display Fluid Dosing Metering Pump Food Grade Gear Pump

|

|

Displacement

|

0.05CC/R -150CC/R(±3%)

|

|

Bus board height

|

80mm-144mm

|

|

Total height

|

155mm-250mm

|

|

Min Inlet Pressure

|

<0.2Mpa

|

|

Working Speed

|

5~200 R/min

|

|

Medium

|

Fluid

|

|

Temperature

|

200℃

|

|

Max Outlet Pressure

|

<30Mpa

|

|

Flow Capacity

|

6-30(+/-30)CC/R

|

|

Sealing

|

Combined seal

|

Supporting use

Gear metering pumps are widely used in dispensing equipment, polyurethane equipment, Hot-melt adhesive equipment, spinning metering equipment, food filling equipment and other industries.

“36 years”

focus on the manufacturing of instruments and meters

Among them, the manufacturing of flow meters has entered the

“top 10”

nationwide

Served over "100+" countries and

"100000+"

customers

Has obtained the "100+" patent certificate and the "National High tech Enterprise Title"

Provide a one-stop solution with customer satisfaction of

"99%"

.

[Obtain Quotation]

[Contact Supplier]

Specifications

|

Model

|

Displacement

(CC/R) |

Pump plate height(B)

|

Total length of pump (A)

|

Min Inlet Pressure

|

Max Outpet Pressure

|

Accuracy

|

Temperature

|

|||||||

|

0.05CC

|

0.05

|

36.94

|

65.94

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

0.15CC

|

0.15

|

24

|

85

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

0.3CC

|

0.3

|

28

|

85

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

0.6CC

|

0.6

|

28

|

85

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

1.2CC

|

1.2

|

32

|

90

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

2.4CC

|

2.4

|

32

|

100

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

3.2CC

|

3.2

|

50

|

103

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

3.6CC

|

3.6

|

135

|

105

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

4CC

|

4

|

38.2

|

120

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

6CC

|

6

|

41.6

|

125

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

9CC

|

9

|

46.4

|

130

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

12CC

|

12

|

51.2

|

135

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

15CC

|

15

|

56

|

140

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

20CC

|

20

|

64

|

145

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

25CC

|

25

|

72

|

155

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

30CC

|

30

|

80

|

160

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

30ACC

|

30

|

83.3

|

215

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

40CC

|

40

|

90

|

215

|

<0.2Mpa

|

<30Mpa

|

+/-3%

|

200℃

|

|||||||

|

50CC

|

50

|

97

|

215

|

|

|

|

|

|||||||

|

60CC

|

60

|

104.4

|

215

|

|

|

|

|

|||||||

|

Note:

Direction of rotation: clockwise from the axis of rotation

|

|

|

|

|

|

|

|

|||||||

Product Show

|

Model

|

6CC

|

9CC

|

12CC

|

15CC

|

20CC

|

25CC

|

30CC

|

|

A

|

130

|

135

|

140

|

145

|

150

|

158

|

165

|

|

B

|

41

|

46

|

51

|

56

|

64

|

72

|

80

|

|

Model

|

0.15CC

|

0.3CC

|

0.6CC

|

1.2CC

|

2.4CC

|

3.2CC

|

3.6CC

|

|

A

|

83

|

85

|

85

|

90

|

100

|

103

|

105

|

|

B

|

28.1

|

30.2

|

32

|

34

|

42

|

47.6

|

50

|

|

Min Inlet Pressure

|

<0.2Mpa

|

|

Working Speed

|

5~200 R/min

|

|

Medium

|

Fluid

|

|

Temperature

|

200℃

|

|

Max Outlet Pressure

|

<30Mpa

|

|

Flow Capacity

|

0.15-3.6(+/-3%)cc/r

|

|

Sealing

|

Combined seal

|

Matching selection tips:

For situations with PLC, it is recommended to choose:

A. Pump+coupling+reducer+servo motor;

B. Pump+coupling+stepper motor;

C. Low viscosity and low speed can be optionally equipped with a stepper motor

Suggested options for situations without PLC: pump+coupling+variable frequency motor+frequency converter

Flammable and explosive locations must be equipped with explosion-proof motors

Hot Searches