- Product Details

- {{item.text}}

Quick Details

-

Keywords:

-

dumpling/ momo/curry puff/samosa making machine

-

Application:

-

Restaurants/hotel

-

Material:

-

Stainless Steel

-

Final product:

-

dumpling/ momo/curry puff/samosa /spring roll

-

Function:

-

Produce Dumpling, etc

-

Usage:

-

Food Processing Industry

-

Feature:

-

cost effective

-

advantage:

-

high capacity and easy operation

-

Stuffing:

-

both meat and vegetable

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Free spare parts

-

Name:

-

dumpling wrapper machine/ curry pufff making machine

-

Keywords:

-

dumpling/ momo/curry puff/samosa making machine

-

Application:

-

Restaurants/hotel

-

Material:

-

Stainless Steel

-

Final product:

-

dumpling/ momo/curry puff/samosa /spring roll

-

Function:

-

Produce Dumpling, etc

-

Usage:

-

Food Processing Industry

-

Feature:

-

cost effective

-

advantage:

-

high capacity and easy operation

-

Stuffing:

-

both meat and vegetable

-

Certification:

-

CE

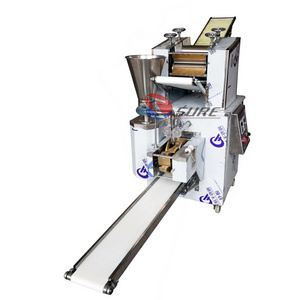

China factory supplied dumpling making machine/ curry puff make machine / samosa wrapper / spring roll machine/ ravioli maker/ gyoza making machine/ Japanese momo producction machine, etc.

This machine is calso called automatic imitation handmade dumpling making machine, it can make Chinese dumpling, Japanese momo, empanada , curry puff, samosa, spring roll etc pastry products by changing different molds. we can customize the mold according to your final product shape and sizes. with high capacity and multi-function, this machine is widely used in restaurant at home and abroad.

This machine mainly consist of dough feeder and roller,stuffing hopper, mold, conveyor, etc. The machine has two inputs namely dough input and stuffing input:

In the dough input, the dough is inserted to produce a skin layer with required thickness and weight. In the stuffing input, the core is inserted and produced according to weight (g) determined by the operator. During automatic operation, both dough and filling are running simultaneously. you can contro the dough and stuffing input speed by contro panel of machine.

The produced skin layer come out and rest on the dumpling/ curry-puff / samosa mold followed by the stuffing on top which come out of from hopper. The mould move forward, clamp tightly, re-open the mould and finally dropped onto conveyor directly. The operation repeats and finally the excess of the left skin layer will be collected for reuse.

|

Model |

JCJZ-130 |

JCJZ-150 |

JCJZ-200 |

|

capacity |

6000pcs/h |

8000pcs/h |

10000pcs/h |

|

power |

1.5kw |

2kw |

2kw |

|

weight |

200kg |

380kg |

450kg |

|

Size |

1200*600*1000mm |

1500*800*1100mm |

1900*800*1500mm |

If you are interested, please feel free to contact me by namecard below , or scan the QR code for quick talk on wechat . we are on service 24hrs .