- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FS77H, YTFS

-

Thickness:

-

1.5-100mm

-

Size:

-

Custom Size, Custom Size

-

Color:

-

colors

-

Application:

-

Machinery

-

Surface:

-

smooth

-

Hardness:

-

70-95A

-

Sample:

-

Avaliable

Quick Details

-

Processing Service:

-

Moulding

-

Place of Origin:

-

Shandong, China, Shandong, China

-

Brand Name:

-

FS, FUSHUN

-

Model Number:

-

FS77H, YTFS

-

Thickness:

-

1.5-100mm

-

Size:

-

Custom Size, Custom Size

-

Color:

-

colors

-

Application:

-

Machinery

-

Surface:

-

smooth

-

Hardness:

-

70-95A

-

Sample:

-

Avaliable

Advantages of urethane

Urethane is a unique material that offers the elasticity of rubber combined with the toughness and durability of metal. Because urethane is available in a very broad hardness range, it allows the engineer to replace rubber, plastic, and metal with the ultimate in abrasion resistance and physical properties. Polyurethane can reduce plant maintenance and OEM product cost. Many applications using this ultra-tough material have cut down-time, maintenance time, and cost of parts to a fraction of the previous figures. The following are other advantages polyurethane has to offer:

· Abrasion resistant

· Oil and solvent resistant

· Load bearing capacity

· Tear resistant

· Excellent noise abatement properties

· Flex-Life

U rethane have better abrasion and tear resistance than rubbers, while offering higher load bearing capacity.

Compared to plastics, polyurethane offer superior impact resistance, while offering excellent wear properties and elastic memory.

Urethane have replaced metals in sleeve bearings, wear plates, sprockets, rollers, and various other parts, with benefits such as weight reduction, noise abatement, and wear improvements being realized.

a

dvantages of urethane Sheet

Urethane Sheet is often used as a replacement for rubber components and provides an obvious upgrade over the traditional material. Polyurethane Sheet has a much improved resistance to wear and can out last other materials by as much as four times. Another advantage is the performance during load and compression, Polyurethane will out perform rubber which will often permanently deform much sooner resulting in the associated components, often vehicle suspension parts becoming loose and causing lack of control and often expensive damage. Its resistance to ageing or perishing, rubber will often degrade over sometimes a short period of time, but this can often be accelerated in UV exposure and the contact with oils and fuels. Polyurethane Sheet is also much more resistant to cutting with sharp edges and is also much more impact resistant.

|

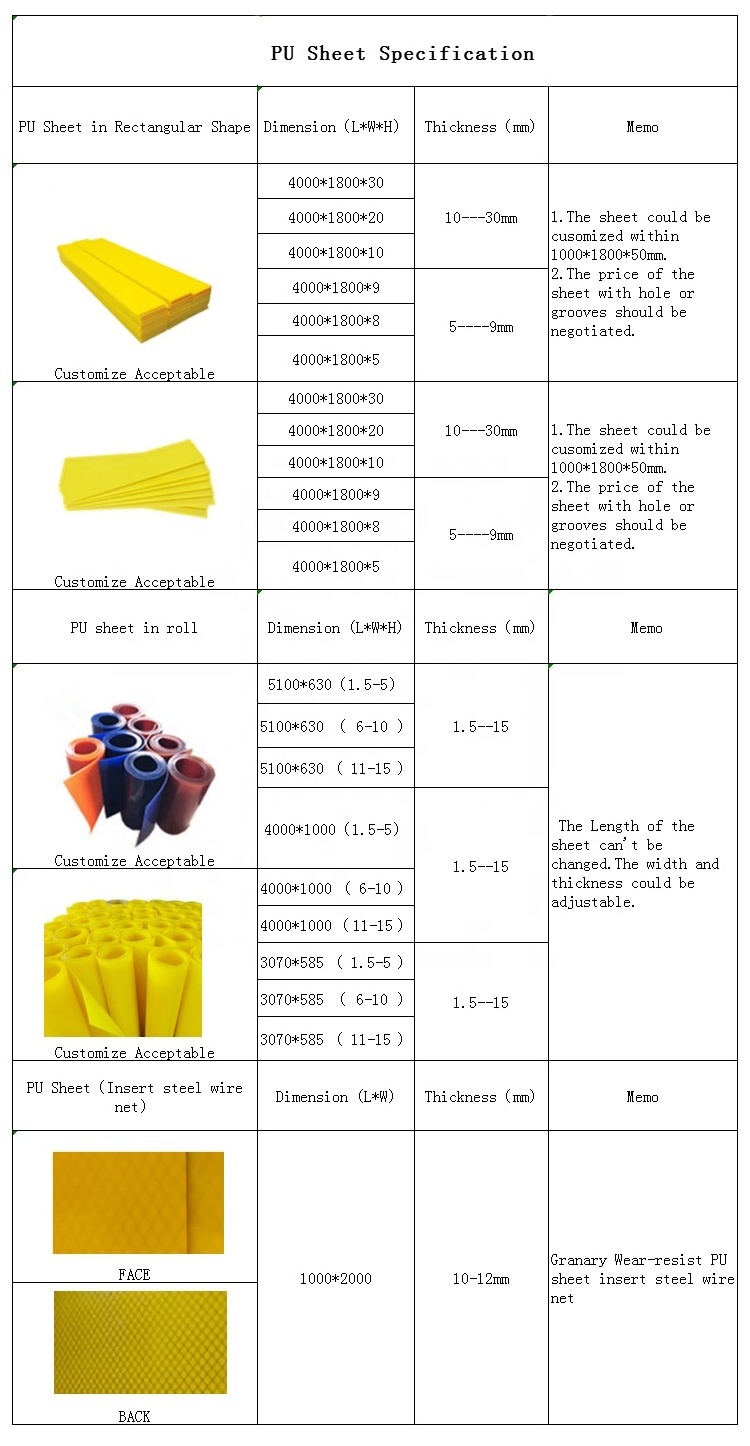

Length X width(mm) |

Color |

Minimum order |

|

|

1.5 ~1 00 mm |

300X300mm,500X500mm 1000X1000mm or customized |

Transparent, light green red, coffee, brown |

100 KG |

|

Density (g/cm³) |

1.15 , 1.25 |

|

|

Color |

Transparent, Translucent, Yellow, Red, Green White, or Custom |

|

|

Sheets Thickness (mm) |

1.5-100mm |

|

|

Regular Size (width × length mm) |

1000*4000mm, 585*3070mm,631*5100mm etc |

|

|

Hardness (shore) |

65~95A |

|

|

Elongation rate |

530%~600% |

|

|

Tensile strength |

255~380 kg/cm² |

|

|

Sample |

1.sample time: within 5-10 days |

|

|

2.Sample charge: According to product details |

||

|

3.Send sample: Via TNT, UPS, Fedex, DHL |

||

|

4.Free sample provided if you need our stock for testing the quality |

||

|

Payment |

T/T , Western Union |

|

|

Delivery Time |

7-15 days according to quantity |

|

|

Shipping Port |

Qingdao port |

|

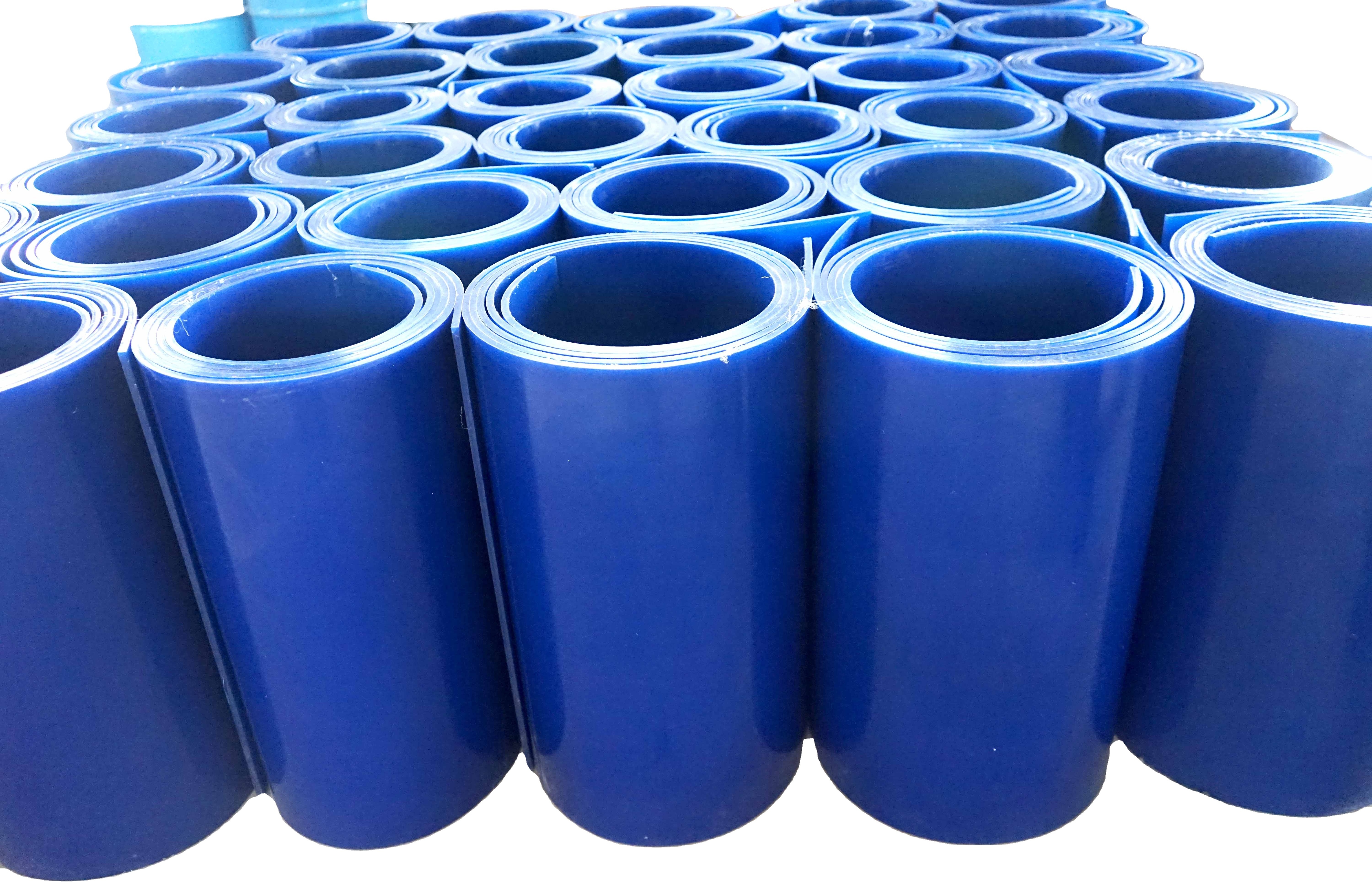

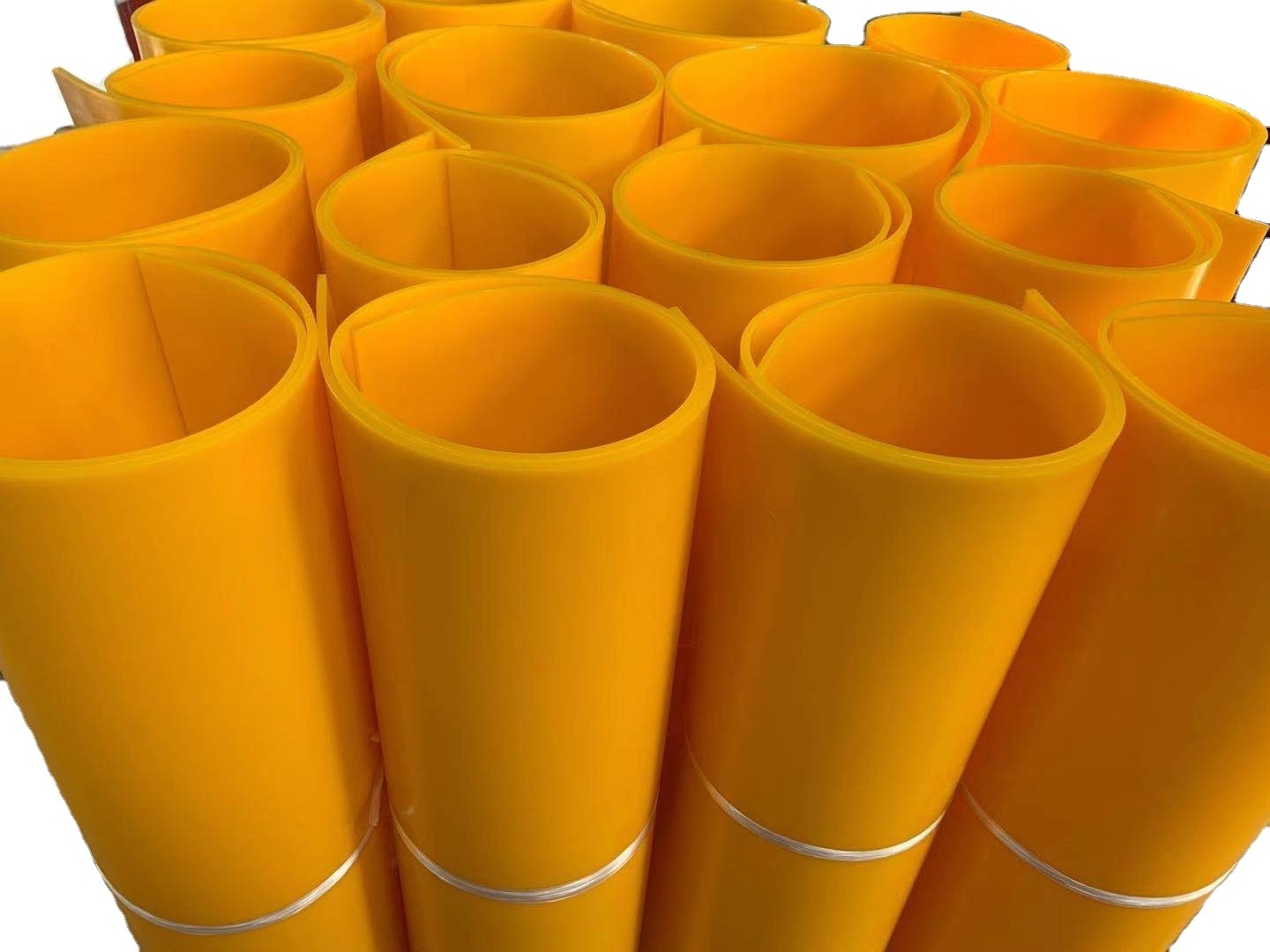

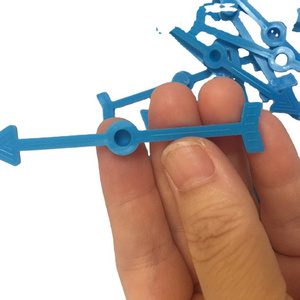

Pictures

Packaging & Shippin g

|

Packaging |

1. Wooden pallet with carton. |

|

2. P lywood pallet with carton. |

|

|

3. Wooden wooden pallet with wooden case. |

|

|

4. According to customer requirements. |

|

|

Delivery |

1. Stock size 3-5 working days. |

|

2. Custom size 8-15 working days. |

FAQ

1. Q:Why Choose us ?

1) Competitive Prices

• Manufacturing's key strength is its ability to manufacture products based on optimal economies of scale,

offering you the most competitive prices in the market.

• With our own in-house engineering design, tooling and fabrication abilities we manufacture a wide range of high quality products including tooling and pre -production prototyping.

Our in-house services allow us to keep costs to a minimum and give us the freedom to cust omized our products to your needs.

2) In Stock

• With a wide range of stock at our warehouse as well as easily accessible stock at our own international production facilities,

we are able to meet your requirements whenever you need it.

3)Customi z ed Products

• We stock a wide range of engineering pu for general engineering applications and offer manufacturing and machining services.

• Customi z ed engineering products, machining and cut to size services are also available.

2. Q: How quickly can a product be produced or repaired?

A: Depending on the workload and the job itself, there is normally a five to ten workday lead-time before a product is made.

We do give priority to breakdowns, especially if they are for regular clients who cannot continue aspects of their business without the plastic repairs being carried out.

We understand that some of our products are used in machines that operate constantly, are in hard-to-reach places within a system,

or are vital to the general running of an operation. Get in touch with us to discuss your needs.

3. Q: What type of cutting services are available ?

A: Here is a great way to save time, we can cut any of our standard items into your custom sizes using our on-site cutting facilities.

We have various levels of service depending on the quantity required. All you need to do is choose your material and then go to "Cutting Service" to choose the level of service you require.

We provide loose cut of any sizes, rollers, fabrications, profiles and mould to suit your needs.

Where special sizes or shapes are required by our customers, we are able to customize these products according to individual requirements.