This model automatic decapper is special equipment for 5-gallon retrieving barrel. It does not damage caps. It adopts computer

control and its capacity can be adjusted.Cap pulling organism from AIRTAC adopt pneumatic adjustment, which solves the problems oftolerance of barrel height and tolerance of barrel's mouth.And increases cap pulling success greatly. 304 stainless machine frame and machine body.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

within 1%

-

Voltage:

-

380v 50hz or by the other

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

xinmao

-

Dimension(L*W*H):

-

by the order

-

Weight:

-

3500 KG

-

Product name:

-

5 Gallon Water Filling Machine

-

Marketing Type:

-

Ordinary Product

-

Machine material:

-

SUS304/316L

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Online support

-

Bottle type:

-

5 Gallon Barrel Water Production Line

-

Motor:

-

Siemens

-

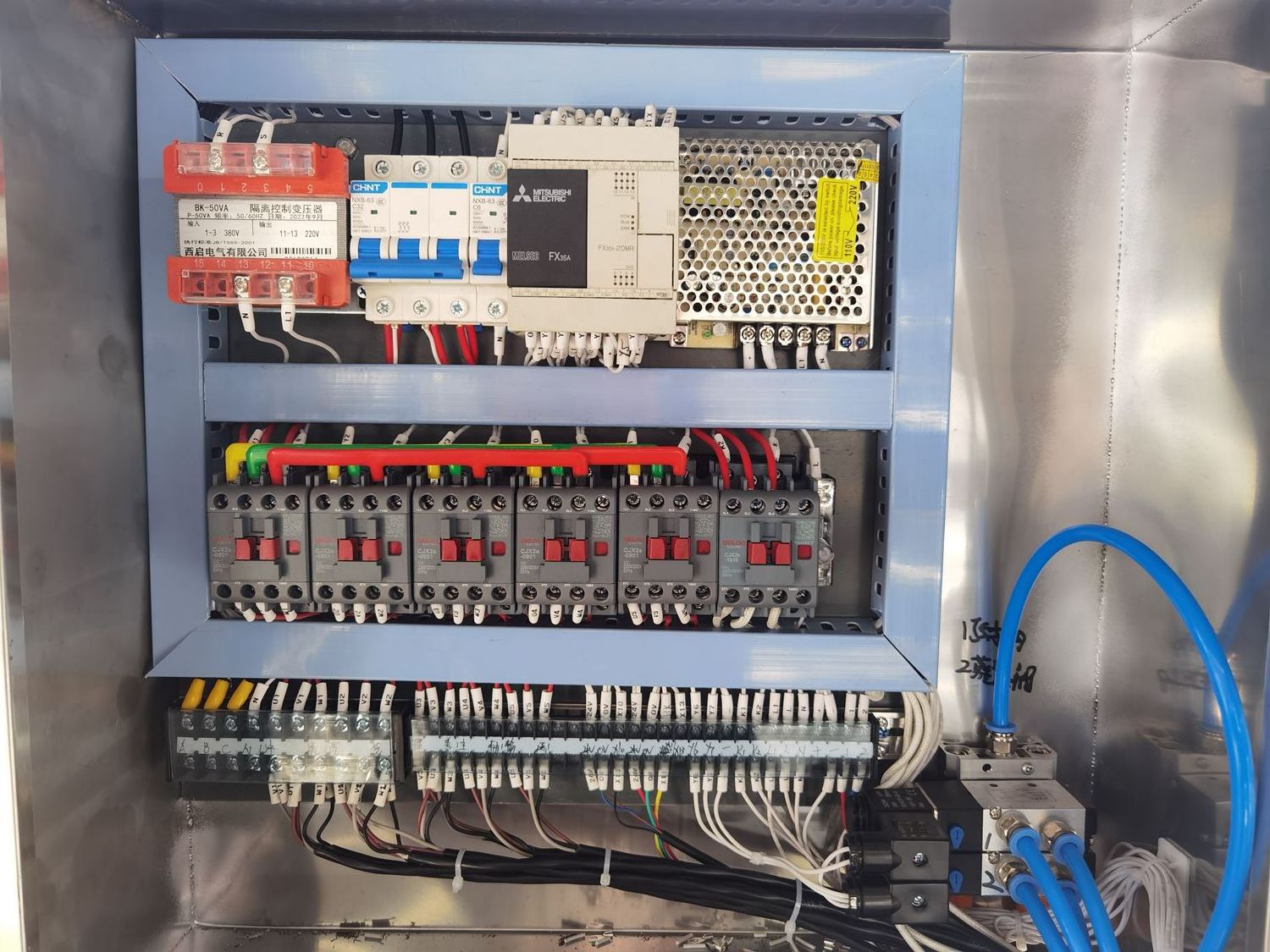

Control system:

-

PLC (Siemens, Mitsubishi)

-

Filling type:

-

ordinary pressure

-

Certification:

-

CE ISO

Quick Details

-

Machinery Capacity:

-

150BPH, 300BPH, 450BPH, 600BPH, 900BPH

-

Packaging Material:

-

Plastic, Wood

-

Filling Material:

-

Water

-

Filling Accuracy:

-

within 1%

-

Voltage:

-

380v 50hz or by the other

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

xinmao

-

Dimension(L*W*H):

-

by the order

-

Weight:

-

3500 KG

-

Product name:

-

5 Gallon Water Filling Machine

-

Marketing Type:

-

Ordinary Product

-

Machine material:

-

SUS304/316L

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Online support

-

Bottle type:

-

5 Gallon Barrel Water Production Line

-

Motor:

-

Siemens

-

Control system:

-

PLC (Siemens, Mitsubishi)

-

Filling type:

-

ordinary pressure

-

Certification:

-

CE ISO

Automatic 5 Gallon Liquid Production Line / 20 Liter Water Filling Machine For Purified Mineral Water

XINMAO QGF series 5 gallon filling machine is designed for producing 5 gallon barrel drinking water.This machine is consisted of rinser,filler and capper. The rinser has several sprays which can be used as for both clean water rinsing and disinfectant rinsing. The disinfectant can be recycled. The machine also has automatic capping device, and cap rinsing device. The wholeproduction line can automatic feeding barrel, rinsing, sterilizing, filling, capping, counting and output.QGF barrel production line is specially used for 5 Gallon barrel drinking water. This machine integrates washing/filling/capping into one unit. It is the good ideal for produce the mineral water/distilled water/pure water equipments. Whole machines are adopt the high quality stainless steel, It's erosion proof ability is strong, easy to washing.

Cap Decapper

Brusher Part

Function: clean the inside and outside of 5 gallon bottles with brush and water.

1. Rotary style to wash the bottle body.

2. Material of machine frame and body: all 304 Stainless Steel.

3. All 304 stainless steel pipeline , valve and connector, fine polish, no death corner

4. Linear washing style with ø350brush 1pc ø200 brush 3pcs 300*3 brush 20pcs

5. Water pump: with 304 stainless steel pump

1. Rotary style to wash the bottle body.

2. Material of machine frame and body: all 304 Stainless Steel.

3. All 304 stainless steel pipeline , valve and connector, fine polish, no death corner

4. Linear washing style with ø350brush 1pc ø200 brush 3pcs 300*3 brush 20pcs

5. Water pump: with 304 stainless steel pump

Washing Part

Filling Part

Capping Part

Online cap washer

Capping machine

Buffering Position

Product Paramenters

|

Model

|

QGF-150

|

QGF-300

|

QGF--450

|

QGF-600

|

QGF-900

|

|

Speed

|

150BPH

|

300BPH

|

450BPH

|

600BPH

|

900BPH

|

|

Power

|

5.3KW

|

5.3KW

|

8KW

|

10.6KW

|

15.9KW

|

|

Compressed Air

|

0.4-0.6mpa

|

0.4-0.6mpa

|

0.4-0.6mpa

|

0.4-0.6mpa

|

0.4-0.6mpa

|

|

Inside washing

|

18S*1

|

18S*1

|

18S*1

|

18S*1

|

18S*1

|

|

Outside washing

|

18S*1

|

18S*1

|

18S*1

|

18S*1

|

18S*1

|

Related Products

Water Treatment System

This water treatment system is made by the

raw water tank through the pretreatment to

reverse osmosis desalting device to get pure

water. Pretreatment is by silica sand filter,

activated carbon filter, sodium ion exchanger

and the precision filter composition. The

reverse osmosis device the core parts adopt

the world famous water pump and reverse

osmosis RO membrane. With a full set of

membrane and washing device.

raw water tank through the pretreatment to

reverse osmosis desalting device to get pure

water. Pretreatment is by silica sand filter,

activated carbon filter, sodium ion exchanger

and the precision filter composition. The

reverse osmosis device the core parts adopt

the world famous water pump and reverse

osmosis RO membrane. With a full set of

membrane and washing device.

Semi-Automatic PET Bottle Blow Molding Machine

The machine is also equipped with muffler and oiling system to lubricate the mechanical

part of the machine.It is very popular and well used in beverages,cosmetics,pharmaceutical industry.

part of the machine.It is very popular and well used in beverages,cosmetics,pharmaceutical industry.

Automatic Palletizing Machine For Barreled Water Filling Supporting Gantry Palletizing Equipment

In the increasingly tense situation in view of the labor, the drinking water treatment works, a large labor force resources, etc.,we are manufacturer for drinking water (water) of actual demand, in development and production of new type of numerical control for 3 to 5 gallons bottled water and automatic palletizing equipment through continuous improvement innovation, thus enable the equipment to achieve higher performance-price ratio, the equipment covers an area of less, low operating cost, Per hour can be 1200 barrels (output can be customized) bottled water according to the requirements of one to three layers (each layer 4*4=16 barrels can be customized multiple specifications), in order to facilitate transportation and storage, the whole equipment can be easily operated by one person, to a great extent, reduce the labor intensity of employees and reduce the entire production line staffing.

Main technical features:

1, the use of slide type self-gravity bucket, server state zero power consumption, low energy consumption; The built-in proximity signal detection mechanism automatically adjusts the palletizing speed according to the output to achieve matching with the filling bottle line.

2, the bucket system adopts the new design pneumatic opposite type bucket clip, does not hurt the barrel mouth and shrink film,does not drop the barrel, the gas consumption is small.

3, lifting system adopts linear bearing slider type soft connection structure, the equipment lifting speed is stable, the accident of mechanical failure protection mechanism and other functions, effectively ensure the protection function of the machine under special fault.

4. The machine can stack 1-3 layers, and the number of stacking layers can be adjusted arbitrarily on the touch screen to meet the different needs of customers.

5, manipulator lifting, translation position using numerical control technology detection and positioning, bucket, bucket position is quite concise and accurate, avoid the high fault rate caused by the excessive use of positioning switch. The bucket adopts servo system, the bucket in the process of lifting and translation at high, low and medium speed operation (low speed bucket clamping - high speed operation - low speed bucket unloading), so as to make the whole operation process coordinated, smooth operation.

6, the machine adopts microcomputer control, man-machine interface operation, running parameters and action process can be freely adjusted on the touch screen, with fault stop, alarm, and other functions.

7. Photoelectric detection and protection switch is set at the lifting and lifting position of the machine. When the machine is running, if abnormal phenomenon is detected at the detection part, the machine will stop immediately and alarm, which protects the safety of production personnel and equipment to a large extent.

Main technical features:

1, the use of slide type self-gravity bucket, server state zero power consumption, low energy consumption; The built-in proximity signal detection mechanism automatically adjusts the palletizing speed according to the output to achieve matching with the filling bottle line.

2, the bucket system adopts the new design pneumatic opposite type bucket clip, does not hurt the barrel mouth and shrink film,does not drop the barrel, the gas consumption is small.

3, lifting system adopts linear bearing slider type soft connection structure, the equipment lifting speed is stable, the accident of mechanical failure protection mechanism and other functions, effectively ensure the protection function of the machine under special fault.

4. The machine can stack 1-3 layers, and the number of stacking layers can be adjusted arbitrarily on the touch screen to meet the different needs of customers.

5, manipulator lifting, translation position using numerical control technology detection and positioning, bucket, bucket position is quite concise and accurate, avoid the high fault rate caused by the excessive use of positioning switch. The bucket adopts servo system, the bucket in the process of lifting and translation at high, low and medium speed operation (low speed bucket clamping - high speed operation - low speed bucket unloading), so as to make the whole operation process coordinated, smooth operation.

6, the machine adopts microcomputer control, man-machine interface operation, running parameters and action process can be freely adjusted on the touch screen, with fault stop, alarm, and other functions.

7. Photoelectric detection and protection switch is set at the lifting and lifting position of the machine. When the machine is running, if abnormal phenomenon is detected at the detection part, the machine will stop immediately and alarm, which protects the safety of production personnel and equipment to a large extent.

Real Picture Of Customer Factory

Hot Searches