- Product Details

- {{item.text}}

Quick Details

-

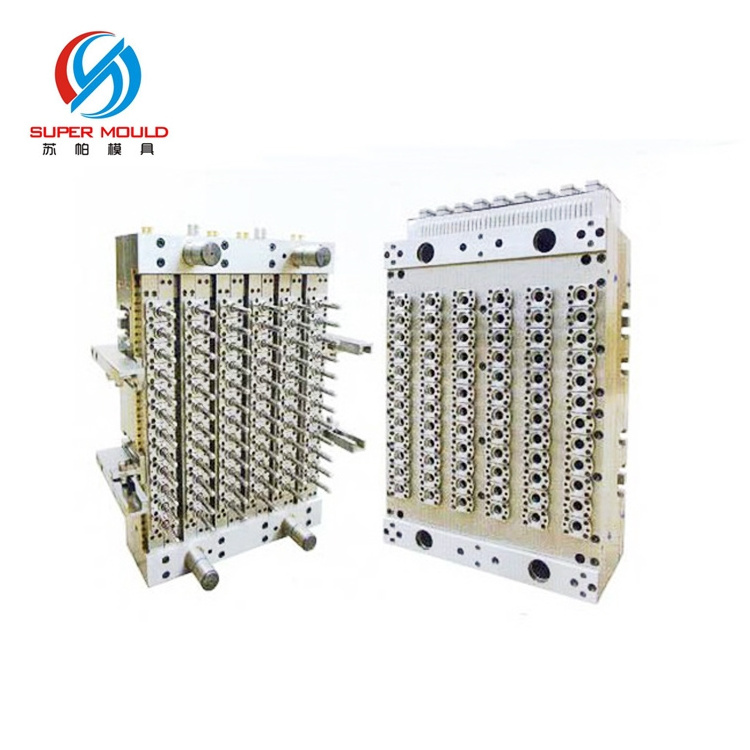

Model Number:

-

SP-44

-

Moldel Number ::

-

72 cavities

-

Shaping Mode::

-

Preform mould

-

Injection model::

-

Plastic mould

-

Runner::

-

Hot runner

-

48 cavities PET preform mould::

-

Preform

-

Neck size:

-

30mm

-

Lock type::

-

Self-lock

-

Lead time::

-

50 days

-

Material::

-

S136

-

Preform material::

-

PET PP

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SP-Mould

-

Model Number:

-

SP-44

-

Moldel Number ::

-

72 cavities

-

Shaping Mode::

-

Preform mould

-

Injection model::

-

Plastic mould

-

Runner::

-

Hot runner

-

48 cavities PET preform mould::

-

Preform

-

Neck size:

-

30mm

-

Lock type::

-

Self-lock

-

Lead time::

-

50 days

-

Material::

-

S136

-

Preform material::

-

PET PP

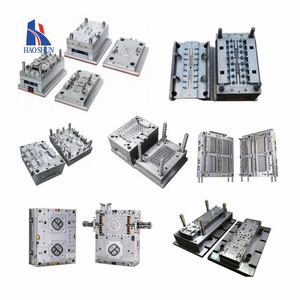

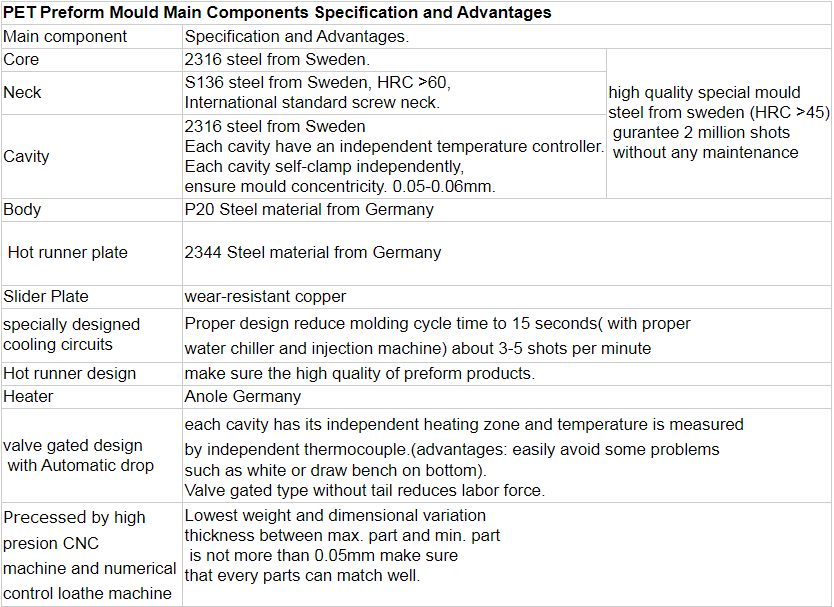

Products Description

|

Mould material

|

P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc

|

|

Runner

|

Cold runner. Hot runner: Yudo/DME/HASCO

|

|

Standard

|

HASCO, DME, LKM

|

|

Specification drawings

|

Pro/E, Auto CAD, Solidwork, CAXA UG, CAD/CAM/CAE.

|

|

Precision machining

|

CNC, milling machine, drilling machine, numerical lathe, all types of lathe

|

|

Surface finish process

|

polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, mirror polishing .

|

|

Shaping mould

|

injection mould

|

|

Service

|

OEM service available, good after-sales service .

|

|

Lead time

|

4-7 weeks, 40 days or according to the real situation .

|

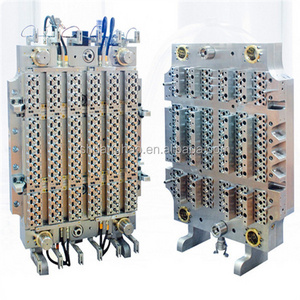

MOULD DATA

|

NO.of cavity

|

12cav.

|

16cav.

|

24cav.

|

32cav.

|

48cav.

|

72cav.

|

|

18g(cm)

|

62*38*43

|

79*38*43

|

88*46*45

|

86*68*48

|

105*68*55

|

110*78*58

|

|

Weight(kg)

|

630

|

810

|

1150

|

1750

|

2450

|

3100

|

|

28g(cm)

|

62*38*45

|

79*38*45

|

88*46*48

|

86*68*52

|

105*68*58

|

110*78*62

|

|

Weight(kg)

|

660

|

850

|

1250

|

1900

|

2600

|

|

|

40g(cm)

|

62*38*48

|

79*38*48

|

88*46*50

|

86*68*55

|

105*68*62

|

110*78*65

|

|

Weight(kg)

|

690

|

890

|

1350

|

2000

|

2750

|

3000

|

The thickness and weight of moulds are in accordance with the tubes,these measurments will change in case the products are improved.

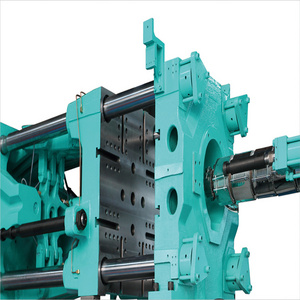

Productivity

Fast cycling due to specially designed cooling circuits

Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time

Standard interchangeable mold components,replacement parts available within 24 hours

Reliability

Rugged design for long life

Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers

Roller cams actuate both the opening and closing actions on the thread splits

Part quality

Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes

Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms.

Productivity

Fast cycling due to specially designed cooling circuits

Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time

Standard interchangeable mold components,replacement parts available within 24 hours

Reliability

Rugged design for long life

Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers

Roller cams actuate both the opening and closing actions on the thread splits

Part quality

Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes

Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms.

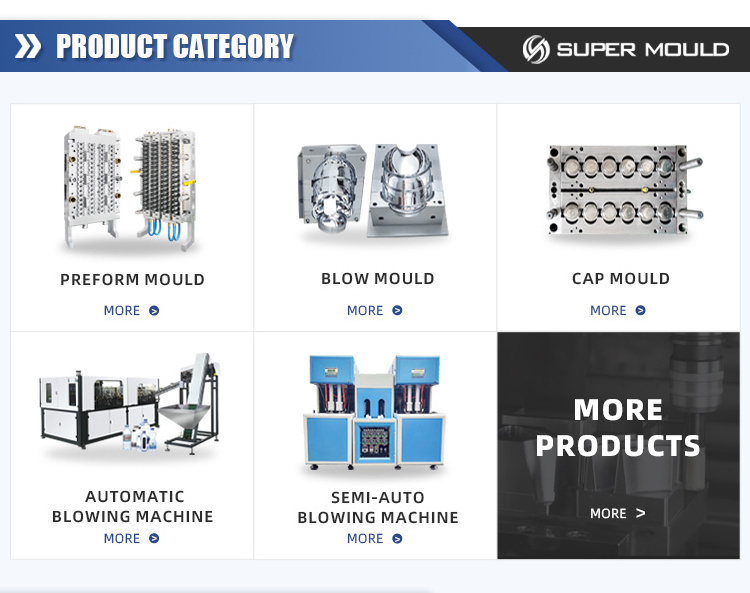

Recommend Products

Hot Searches