Our manufacturing facilities are certified to the ISO TS16949 standard. We are also an approved supplier to many large OEM equipment manufacturers in the mobile industry. Mainly serving North America and beyond, we offer high quality products at very affordable pricing. We take pride in our flexible delivery programs and offer a competitive warranty, be assured, we stand by our product.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HCIC

-

Place of Origin:

-

Shandong, China

-

Pressure:

-

hydraulic

-

Structure:

-

hydraulic

-

Weight:

-

5

-

Rod Diameter:

-

25-1000

-

Outer Tube Diameter:

-

40-1550

-

color:

-

customized

-

Brand:

-

HCIC

-

Standard or Nonstandard:

-

nonstandard

-

After Warranty Service:

-

Online support

Quick Details

-

Warranty:

-

1 Year

-

Maximum Stroke:

-

15500

-

Inner Tube Diameter:

-

38-1500

-

Brand Name:

-

HCIC

-

Place of Origin:

-

Shandong, China

-

Pressure:

-

hydraulic

-

Structure:

-

hydraulic

-

Weight:

-

5

-

Rod Diameter:

-

25-1000

-

Outer Tube Diameter:

-

40-1550

-

color:

-

customized

-

Brand:

-

HCIC

-

Standard or Nonstandard:

-

nonstandard

-

After Warranty Service:

-

Online support

Product Description

HCIC is a professional hydraulic manufacturer, mainly engaged in hydraulic system design, manufacture, installation, transformation, commissioning and hydraulic components brand sales and technical services.

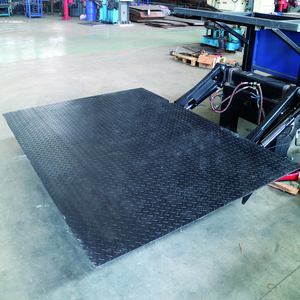

Details Images

Manufacturing Technique

Designing

If we develop, design and also manufacture most of the components ourselves, then it is obvious we are the best choice to assemble them. The assembly of hydraulic components and systems places high demands on accuracy , precision and hygiene. At HCIC you will find committed technicians that have vast knowledge and experience of hydraulic assembly

Machine processing

Precision and flexibility in its sharpest form. At our plant in Jinan, we have a number of CNC controlled machines with automatic tool exchange and up to five axes that permit rational processing on all six sides of a work piece at once. Our skilled operators produce components with tolerance demands down to a few hundredths of a millimeter, which is a prerequisite for our own developed hydraulic components.

Crome Plating

Once the cylinder is engraved, it is clean coated with a final layer of chromium.

Welding

We have all the welding expertise necessary to produce customized solutions. We weld components and complex designs in stainless steel and structural steel, both manually and in robots. Large recurring welding work is handled in our robot installations to streamline production and ensure continuous quality.

DESIGN

Complete design system, comply with ISO standards.

MATERIAL

Purchase from listed steel comapny that is guaranteed.

MACHINING

CNC Machining Center and CNC Lathe&Milling to ensure the TOLERANCE.

CHROME-PLATING

Owned plating plant, coating thickness and quality assurance.

SHOT-BLASTING SURFACE

Provide surface spray adhesion, for longer service life.

PANASONIC WELDING ROBOT

Full weld, high strength and quality parts.

SEAL KIT

Heracles, Parker, NOK, HALLITE. etc

CLEAN MACHINE

Clean all parts then do the assembly.

ASSEMBLY AND TEST

Pressure test each one after assembly.

Performance Test

HCIC have professional performance testing before delivery.The hydraulic cylinder testing capabilities include cylinder friction test, cycle test, impulse endurance test, drift rate test (piston seal leakage), proof pressure test (apply 150% rated pressure in 5 minutes). The hydraulic cylinder test system can be configured for testing single-acting and double-acting hydraulic cylinders.

Product packaging

PLYWOOD BOX

Suitable for packing small hydraulic cylinders with standard shape and large quantity.

IRON FRAME BOX

Suitable for hydraulic cylinders with larger weight and size.

Contact

Hot Searches