- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Echo

-

Dimension(L*W*H):

-

2900*2050*1650mm(L*W*H)

-

Weight:

-

2500KGS

-

Product name:

-

Vacuum Packaging Machinery

-

Usage:

-

Vaccum Packaging Machine

-

Chamber type:

-

Double Vacuum Chamber Sealer

-

Material:

-

SS304

-

Keyword:

-

Vacum Food Packs

-

Capacity (times/ min):

-

10-60 Bag/min

-

Payment Item:

-

TT30% down,70%balance before shipping

-

Bags Size:

-

W:80-160mm, L:100-240mm

-

Error:

-

≤±1%

-

Filling Volume:

-

20-1000g (Depending on type of products)

-

Certification:

-

CE Certificate

Quick Details

-

Packaging Type:

-

Bags, Pouch, Stand-up Pouch

-

Packaging Material:

-

Plastic, Paper

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Echo

-

Dimension(L*W*H):

-

2900*2050*1650mm(L*W*H)

-

Weight:

-

2500KGS

-

Product name:

-

Vacuum Packaging Machinery

-

Usage:

-

Vaccum Packaging Machine

-

Chamber type:

-

Double Vacuum Chamber Sealer

-

Material:

-

SS304

-

Keyword:

-

Vacum Food Packs

-

Capacity (times/ min):

-

10-60 Bag/min

-

Payment Item:

-

TT30% down,70%balance before shipping

-

Bags Size:

-

W:80-160mm, L:100-240mm

-

Error:

-

≤±1%

-

Filling Volume:

-

20-1000g (Depending on type of products)

-

Certification:

-

CE Certificate

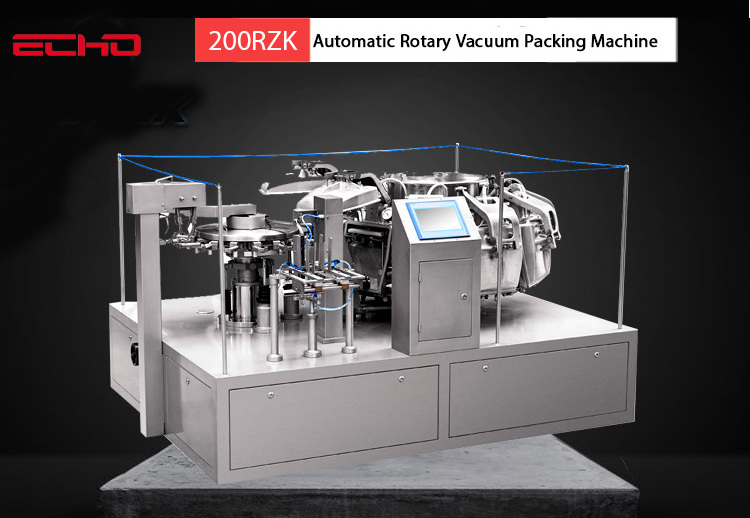

Automatic Chicken Meat Bar Vacuum Packing Machine

Machine Features:

1. Using high technology such as micro computer display and graphic touch panel, the machine can be easily operated and maintained.

2. Being high-performance and high-durability, the filling machine rotates intermittently to fill the product easily while vacuum machine rotates continuously to enable smooth running

3. The width of grippers in filling machine can be adjusted at once by a motor while those in the vacuum chambers are needn't to adjust. The main section of machine are made of stainless steel for excellent durability and hygiene.

4. All filling zone and vacuum chambers are washable.

5. Weighing machine and liquid&paste doser can be combined with this machine Status in the vacuum chamber can be checked through the transparent plastic vacuum shell lids.

We can customize the suitable one for you according to your requiredment.

Just Tell us : Weight or Bag Size required.

| The Main Technical Parameters | |

| Model | MR8-120ZK/MR8-200ZK/MR-160ZK |

| Bag Size | Width:70-120mm/120-200mm, Length:80-160mm/150-300mm |

| Filling Volume | 10-500g (Depending on type of products) |

| Capacity |

30-100bags/min (The speed depends on type of products and packaging material used) The highest can be 100 packs / minute Zipper Bag The heghest can be 40packs/minute |

| Package Accuracy |

Error≤±1% |

| Total Power | 2.5KW/5.5kw (220V/380V,3PH,50HZ) |

| Demension | 2100*1400*1700 mm/2600*1900*1700(Length*Width*Height) |

| Weight | 1600KGS/3000kgs |

| Compress Air Requirement | ≥0.8m³/min supply by user |

| Parts of Machine | ||||||||||

| Parts | PLC | Touch Screen | Frequency Conveter | Vacuum Pump | Printer | Main Motor | Temperature Controllor | Proximoty Swith |

Magnetic Value |

Cylinder |

| Brand | SIEMENS | SIEMENS | TOSHIBA | ORION | SHENG LONG | EVERGEAR | AISET | OMRON | FESTO | AIRTAC |

| Oringin | Germany | Germany | Japan | Japan | China | China | China | Japan | Germany | China |

| Can replace parts as needed | ||||||||||

| Pouch Type | All type of heat sealable performed side seal bags, Portable bag, edging bag 4 sides, edging bag 3 sides, etc. |

| Application Product |

1. Solid Product 2. Granule Product 3. Liquid Product 4. Thick liquid Product 5. Materials that can pack in bag |

| Work Process | |

|

Safety Measures |

1.No bag – no filling- no sealing, Bag opening miss- no filling-no sealing,machine alarm. 2.Machine stop or alarm when the air pressure is abnormal. 3.Error position display at the control panel 4.Control panel locate on the right side top of the machine. 5.Outside of the machine and all the parts which touch production all made by stainless steel. 6.There are several safety doors made by aluminum Profile Frame. 7.The doors are equipped with safety proximity sensors. 8.Machine surface can be washed by water and brushed by cloth. |

|

Product Process |

Station 1 Giving BagStation 2 Date Printing (option) Station3 Opening Bag Station4 Filling and consolidate 1 Station5 Filling and consolidate 2(Option) Station6 Buffering Station7 Vacuum and sealing Station8 Forming and Output |

|

Stations are based on customer requirements for adjusting. |

|

2.according to the special requirements of customers, personalized customized products;

3. Train technicians for customers free of charge;

4. Free professional technical engineers to plan the site on site and design the best process and plan.

6. Assist the client in drafting the construction plan;

ECHO have the trained team to follow your orders methodically to guarantee the products can be finished on time with high quality.

2. Parts Replacement , Don’t worry about the parts damaged or not sold after the machine is sold.we have a field factory with hundreds of enployees to serve you.

3. Engineer Asssignment , Lifelong maintentance,If your equipment breaks down,we will arrange engineers to repair it.

4. Online Instruction , We open online services,as long as your equipment failure,our engineers will be the first time for a one-to-one trou-bleshooting.

5. Feedback Survey, The engineer is required to bring a questionnaire to fill in the satisfaction with the engineer and the use of the equipment.