- Product Details

- {{item.text}}

Quick Details

-

Side Ground:

-

Included

-

Product Name:

-

Gear Rack

-

Tape:

-

Straight Rack

Quick Details

-

Place of Origin:

-

China Guangdong (Mainland)

-

Pressure Angle:

-

20 Degree

-

Tooth of treatment:

-

milled

-

Side Ground:

-

Included

-

Product Name:

-

Gear Rack

-

Tape:

-

Straight Rack

Product Description

Aodisi ZCCT ,Module 1.5-12, 106-27 Tooth, Hardened & Ground Steel Straight Gear Rack

Aodisi racks are made for high precision linear motion applications,

change rotational motion into linear motion.

We offer a large selection of racks with low cost ranging from module 1 to 12 and lengths from 100 to 3000 mm with our Impeccable intellectual equipment,huge R & D team,quality assurance that accurate to silk meter, Aodisi is your reliable partner.

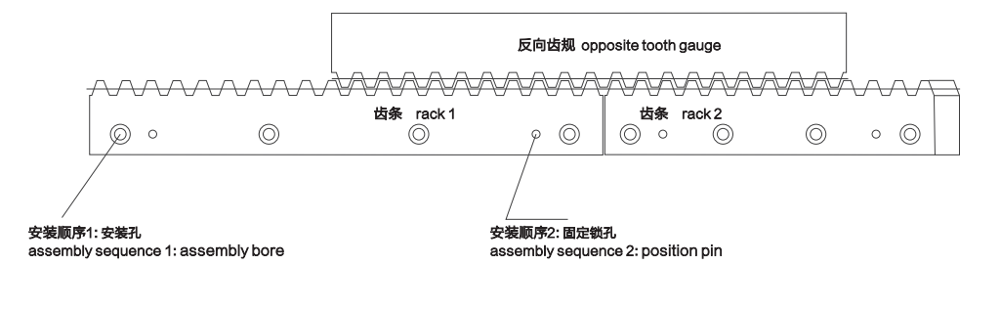

How to mount racks on a mounting base?

Pls. note instruction of rack assembly steps.

In order to assemble connected racks more smoothly, two ends of a standard rack would add half tooth which is convenient for next half tooth of next rack to be connected to a complete tooth.

The folloiwng drawing show how 2 racks connect and tooth gauge can control pitch position accurately.

with regard to coonection of helical racks, it can be connected accurately by opposite tooth gauge (joining gauge rack).

1. when connecting racks, we recommend lock bores on the sides of rack first and lock bores by the sequence of the foundation, with assembing the tooth gauge, pitch position of racks can be assembled accurately and completely.

2. last, lock the poisition pins on 2 sides of rack, the assembly is completed.

3. Test and run the pinion on the rack to confirm the following,

A.make no large vibrations and abnormal noise.

B.has appropriate backlash.

C.has no uneven teeth-contact occurred.

A.make no large vibrations and abnormal noise.

B.has appropriate backlash.

C.has no uneven teeth-contact occurred.

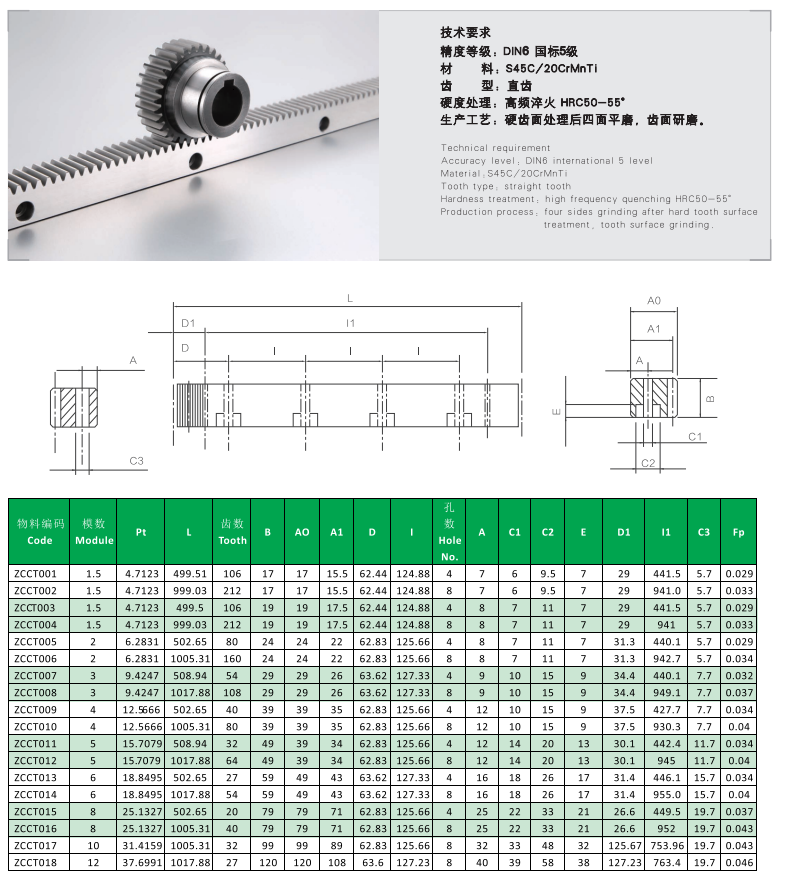

Technical Requirement

- Precision Grade: DIN Grade 6 , International Grade 5

- Material: S45C/20CrMnTi

- Tooth Type: straight tooth rack

- Heat Treatment: high frequency quenching HRC50-55°

- Production process: four sides grinding after hard tooth surface treatment, tooth surface grinding

- runs smoothly

- Large selections of modules and number of teeth are available here at Aodisi, length and mounting hole machining can be specified.

Main standard dimensions for your kind choice, other customized sku is available but need more production leadtime.

Hot sale

Contact us

Hot Searches