- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

60

-

Weight (KG):

-

100 KG

-

Place of Origin:

-

ZHENGZHOU

-

Brand Name:

-

Xianglu

-

Voltage:

-

110V/220V/380V/440V

-

Dimension(L*W*H):

-

110* 80*140cm

-

Power (kW):

-

2.2 kW

-

Size (cm):

-

110* 80*140

-

Power(kw):

-

2.2

-

Rotating speed:

-

13-14

-

Single mixing capacity:

-

35kg

-

Weight(kg):

-

100kg

Quick Details

-

Barrel Volume (L):

-

60L

-

Max. Loading Volume (L):

-

60 L

-

Range of Spindle Speed(r.p.m):

-

1 - 14 r.p.m

-

Max. Loading Capacity:

-

60

-

Weight (KG):

-

100 KG

-

Place of Origin:

-

ZHENGZHOU

-

Brand Name:

-

Xianglu

-

Voltage:

-

110V/220V/380V/440V

-

Dimension(L*W*H):

-

110* 80*140cm

-

Power (kW):

-

2.2 kW

-

Size (cm):

-

110* 80*140

-

Power(kw):

-

2.2

-

Rotating speed:

-

13-14

-

Single mixing capacity:

-

35kg

-

Weight(kg):

-

100kg

Production Process

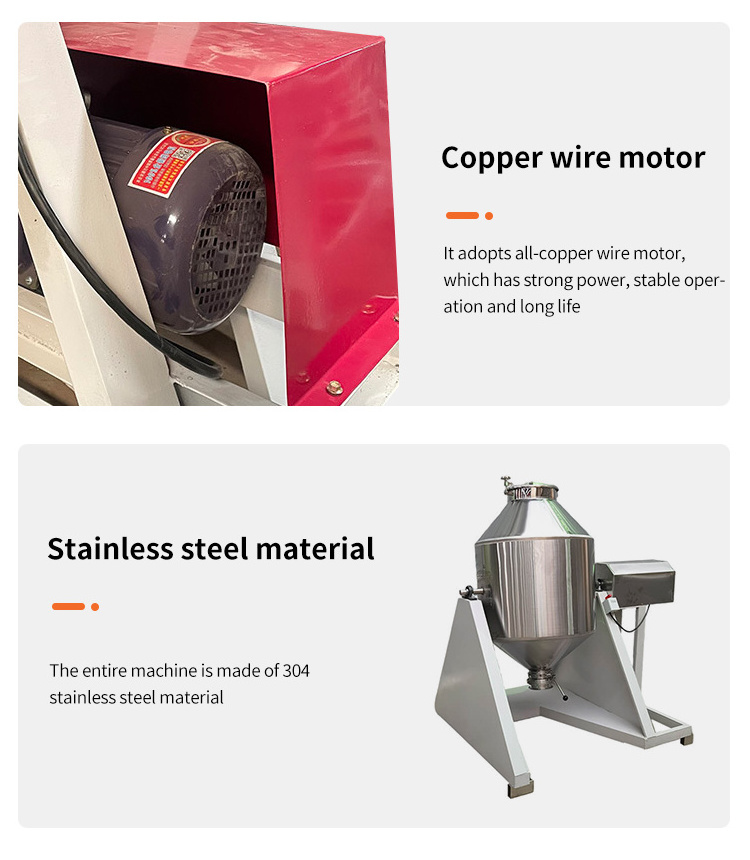

Stainless steel drum dry powder mixer is a new type, fine container rotation, stirring type mixing equipment, used for uniform mixing of various powdery and granular materials, with a high degree of mixing, and can also have a good mixing degree for ingredients with little addition.

This machine adopts mechanical seal, the powder will not leak, and the bearing service life is long: the machine has high mixing efficiency, high work efficiency, low labor intensity and convenient operation; It can be used in magnetic powder, ceramics, chemical, pharmaceutical, feed and other industries.

This machine adopts mechanical seal, the powder will not leak, and the bearing service life is long: the machine has high mixing efficiency, high work efficiency, low labor intensity and convenient operation; It can be used in magnetic powder, ceramics, chemical, pharmaceutical, feed and other industries.

Features of stainless steel drum dry powder mixer:

The waist drum type stainless steel mixer has the characteristics of simple structure, reasonable structure, convenient

maintenance, small power, reliability, high mixing uniformity, no residue and good sealing.

It is suitable for the mixing of powder additives and trace elements in many industries, clean and hygienic and non-oxidizing.

The waist drum type stainless steel mixer has the characteristics of simple structure, reasonable structure, convenient

maintenance, small power, reliability, high mixing uniformity, no residue and good sealing.

It is suitable for the mixing of powder additives and trace elements in many industries, clean and hygienic and non-oxidizing.

Stainless steel drum dry powder mixer use:

1 metal powder: aluminum. Lead, zinc, copper, iron, nickel, alloys, magnetic materials and other metals are powder;

2. Chemical chemical materials such as resin, plastic, rubber additives, dyes, pesticide fillers, etc.;

3. Food designed in line with health indicators: flour, cocoa, coffee, condiments, additives, etc.;

4. Chinese and Western APIs, Western medicines, and proprietary Chinese medicines designed according to GMPS requirements;

5. Grain grains, corn, beans, sesame and other crops, hulling, impurities;

6. Abrasives: glass powder beads, alumina, corundum, chlorine carbon, emery, quartz sand and other abrasive materials;

7. Feed processing powders, granules, additives, etc.;

8. Raw material screening of fertilizers and fine screening of other finished products;

9. Screening of various mineral raw powders in minerals and their processed finished products;

10. Dimension: wood, activated carbon, carbon black and other fiber materials;

11. Recycling of various materials and resources such as electric solder, refractory materials, phosphors, etc.

1 metal powder: aluminum. Lead, zinc, copper, iron, nickel, alloys, magnetic materials and other metals are powder;

2. Chemical chemical materials such as resin, plastic, rubber additives, dyes, pesticide fillers, etc.;

3. Food designed in line with health indicators: flour, cocoa, coffee, condiments, additives, etc.;

4. Chinese and Western APIs, Western medicines, and proprietary Chinese medicines designed according to GMPS requirements;

5. Grain grains, corn, beans, sesame and other crops, hulling, impurities;

6. Abrasives: glass powder beads, alumina, corundum, chlorine carbon, emery, quartz sand and other abrasive materials;

7. Feed processing powders, granules, additives, etc.;

8. Raw material screening of fertilizers and fine screening of other finished products;

9. Screening of various mineral raw powders in minerals and their processed finished products;

10. Dimension: wood, activated carbon, carbon black and other fiber materials;

11. Recycling of various materials and resources such as electric solder, refractory materials, phosphors, etc.

|

Model

|

Size (cm)

|

Power(kw)

|

Rotating speed

|

Single mixing capacity

|

Weight(kg)

|

|

XLGS-30P

|

110* 80*140

|

2.2

|

13-14

|

35kg

|

100kg

|

|

XLGS-50P

|

117*87*140

|

3

|

13-14

|

55kg

|

105kg

|

|

XLGS-100P

|

135*100*155

|

3

|

13-14

|

150kg

|

150kg

|

|

XLGS-200P

|

155*120*175

|

3

|

13-14

|

220kg

|

210kg

|

|

XLGS-300P

|

163*121*185

|

3

|

13-14

|

260kg

|

260kg

|

Factory

Hot Searches