- Product Details

- {{item.text}}

Quick Details

-

Standard:

-

Military Standard

-

Material:

-

Engineering plastics PP

-

Process:

-

Injection Molded

-

External:

-

570*418*285mm (22.4"x16.5"x11.2")

-

Internal:

-

508*356*254mm (20"x14"x10")

-

Depth:

-

48+206 mm

-

Net Weight:

-

5.2 KG (11.46 lbs)

-

Color:

-

Black/Green or customized

-

Protective level:

-

IP67

-

Temperature Resistant:

-

-40~90°C

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Tricases

-

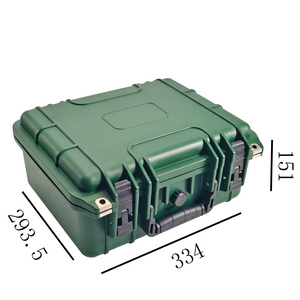

Model Number:

-

M2620

-

Standard:

-

Military Standard

-

Material:

-

Engineering plastics PP

-

Process:

-

Injection Molded

-

External:

-

570*418*285mm (22.4"x16.5"x11.2")

-

Internal:

-

508*356*254mm (20"x14"x10")

-

Depth:

-

48+206 mm

-

Net Weight:

-

5.2 KG (11.46 lbs)

-

Color:

-

Black/Green or customized

-

Protective level:

-

IP67

-

Temperature Resistant:

-

-40~90°C

China Tricases M2620 pelic cases

(1)The detail of M2620

(2)The application example of our products

(3)You can also choose our other products

Injection molded cases(M-series)

| Item | Material | Externalsize (mm) | Internal size(mm) | Depth(mm) | Color | Weight(kg) | Pull rod |

| M2100 | PP | 395*299*148 | 334*237*132 | 32+100 | B/Y/G | 1.78 | No |

| M2200 | PP | 413*328*168 | 381*267*152 | 48+104 | B/Y/O | 2.3 | No |

| M2360 | PP | 464*358*208 | 432*297*193 | 48+145 | B/Y/G | 2.86 | No |

| M2400 | PP | 493*395*185 | 462*334*170 | 48+122 | B/Y | 2.916 | No |

| M2500 | PP | 587*358*221 | 525*297*192 | 48+144 | B/Y | 4.95 | Yes |

| M2608 | PP | 570*418*228 | 508*356*220 | 48+172 | B/G | 4 | No |

| M2620 | PP | 570*418*285 | 508*356*254 | 48+206 | B/G | 5.2 | Yes |

| M2720 | PP | 624*498*285 | 563*437*254 | 48+206 | B | 7.5 | Yes |

| M2750 | PP | 624*498*353 | 563*437*323 | 48+275 | B | 8 | Yes |

| M2950 | PP | 802*522*298 | 741*461*267 | 78+189 | B | 8.9 | Yes |

19" Rack Cases (RU-series)

| Item | Material | External size(mm) | Frame size(mm) | Depth(mm) | Dampener | Wheels | Color |

| RU040 | LLDPE | 760*621*364 | 181*483*450 | 100+560 | 8 | 2/4 | Green |

| RU060 | LLDPE | 860*592*446 | 270.5*483*600 | 90+680 | 8 | 2/4 | Green |

| RU080 | LLDPE | 860*592*535 | 359.5*483*600 | 90+680 | 8 | 2/4 | Green |

| RU110 | LLDPE | 850*621*675 | 493*483*550 | 100+650 | 8 | 2/4 | Green |

Rotational Cases (RS-series)

| Item | Material | External size(mm) | Internal size(mm) | Weight(kg) | Wheels | Color | Level |

| RS820 | PE | 800*530*380 | 700*445*350 | 15 | Yes | Green | IP65 |

| RS830 | PE | 800*600*560 | 730*530*450 | 18 | No | Green | IP65 |

| RS860 | PE | 961*697*398 | 871*615*355 | 20 | Yes | Green | IP65 |

| RS870 | PE | 1100*530*360 | 1020*450*340 | 18 | Yes | Green | IP65 |

| RS880A | PE | 1200*800*620 | 1100*730*600 | 33 | No | Green | IP65 |

| RS880B | PE | 1200*800*700 | 1100*730*680 | 37 | No | Green | IP65 |

| RS890 | PE | 2120*1070*625 | 2000*960*600 | 65 | Yes | Green | IP65 |

Who we are?

We come form China,and located at the economic centre of China,Shanghai,we focus

on R&D and produce of protect cases,main product contain three types,that are

Injection Molded Hard Cases(M Series),Rotational Hard Cases(RS-Series),19 Inch

Rack Cases(RU-Series),we are committed to provide customers with best products

and now we have already become the supplier of the milit,also have many customers

abroad, America, Japan,Africa, MidEast,South Korea and so on .Adhering to the spirit

of "professional, high- quality, efficient, honest ", we make an succeed in market and

get priase from the customers.We hope make a good cooperation with you,and we

wait f or you in China.

Why choose us

1. We have rich experience in rotational molding processing, professional in the rotational moulding products.

2. We can offer the whole system services, from product & mould design to the finished plastic products.

3. Our experienced and highly skilled technical design team use advanced CAM software (like UG, Solidworks, Auto CAD , Pro/E) to translate your ideas, pictures, drawings and prototypes into high quality, accurate molds with no pinholes at all-ensuring that the end product has uniform wall thickness and smooth surface. Full design, manufacturing process control rotational mold, CNC machining ,allows us to efficiently ,durability complete rotational mold.

4. High-efficiency lead time-Generally speaking, we can finish one mould and the first sample in around 30 days. Even much shorter for the smaller projects.

5. OEM: We have high –tech equipments in mold workshop, such as rotational equipment,Rock and Roll, Pulveriser and so on.

How contact me?