The fiber laser cutting machine adopts Shanghai Weihong control system. This system is based on Windows XP Chinese and English operation interface. It has high reliability, high performance, intelligence and network, etc. It is cost-effective, easy to operate and easy to use.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Weihong

-

Cutting Area:

-

1500*6000mm

-

Cutting Thickness:

-

Stainless steel 10mm;Carbon steel 20mm

-

Control Software:

-

Weihong

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jiaxin

-

Weight (KG):

-

5000 KG

-

Product name:

-

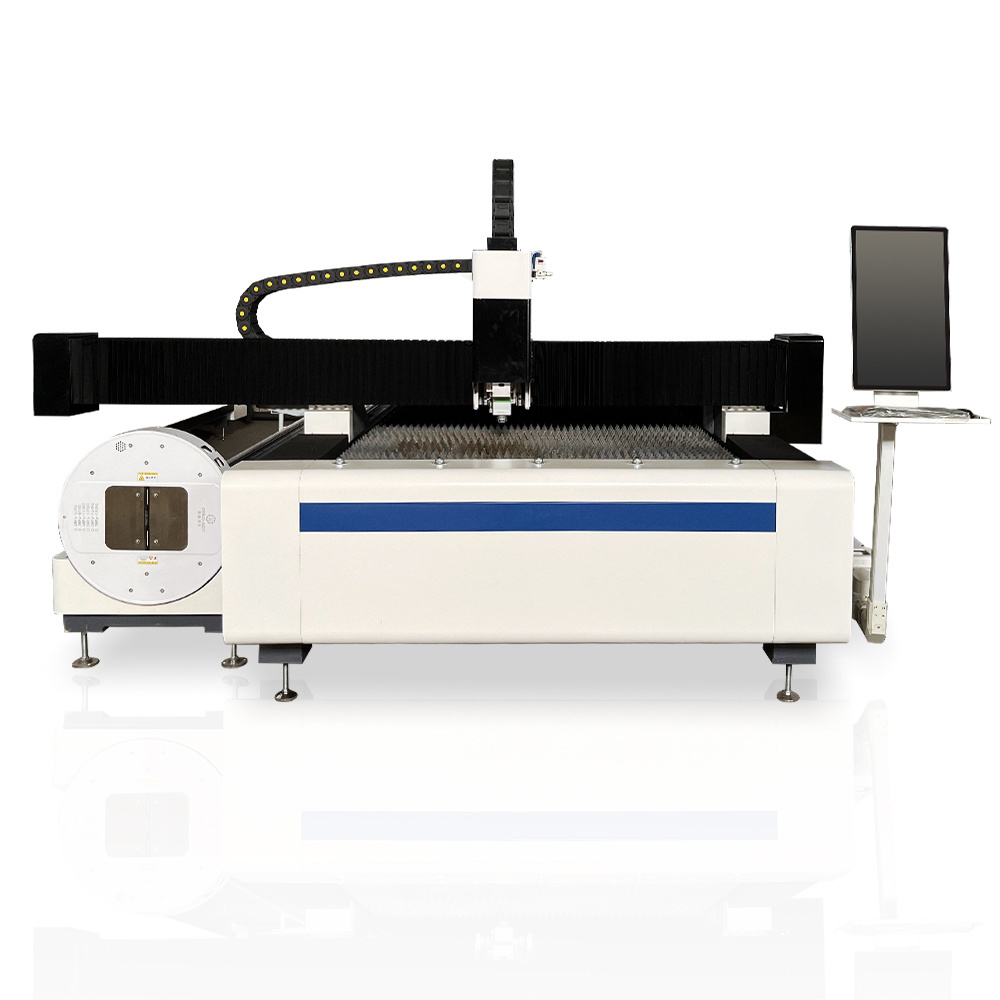

1560 CNC Laser Cutting Machine

-

Cutting thickness:

-

Stainless steel 10mm;Carbon steel 20mm

-

Cutting speed:

-

0-32000mm/min

-

Working area:

-

1500*6000mm

-

Control system:

-

Weihong

-

Move precision:

-

±0.05

-

Lifting stroke:

-

0-150mm

-

Input power:

-

AC380V/50Hz;AC220V/50Hz

-

Laser wavelength:

-

1080mm

-

Drive Way:

-

Precision rack bilateral drive

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

32000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Weihong

-

Cutting Area:

-

1500*6000mm

-

Cutting Thickness:

-

Stainless steel 10mm;Carbon steel 20mm

-

Control Software:

-

Weihong

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jiaxin

-

Weight (KG):

-

5000 KG

-

Product name:

-

1560 CNC Laser Cutting Machine

-

Cutting thickness:

-

Stainless steel 10mm;Carbon steel 20mm

-

Cutting speed:

-

0-32000mm/min

-

Working area:

-

1500*6000mm

-

Control system:

-

Weihong

-

Move precision:

-

±0.05

-

Lifting stroke:

-

0-150mm

-

Input power:

-

AC380V/50Hz;AC220V/50Hz

-

Laser wavelength:

-

1080mm

-

Drive Way:

-

Precision rack bilateral drive

Product Description

fiber laser cutting machine cnc laser cutting machine for aluminum metal sheet

The feature of fiber laser cutting machine:

1) Mechanical structure adopts gantry styles, cross girder and lather bed are made of welding structure.

2) Its laser cutting CNC control system is easy to learn and simple to operate.

3) Its servo motor-driving system adopts rack transmission and straight line-guiding to ensure the runing speed and reliability of the system.

4) Its racks adopt the fully enclosed protection device to avoid dust pollution, which improves the lifetime of transmission parts and ensure its motion accuracy.

Detailed Images

Full-function Control System

Cutting Head

Adopting the German Precitec self-adjusting focusing fiber laser cutting head, the performance is stable and reliable, and the cutting speed is achieved while ensuring the best cutting quality

Laser

The fiber-optic laser has high electro-optical conversion efficiency, and the conversion efficiency is more than 30%, which can greatly save power consumption during operation, save operating cost, and achieve the highest production efficiency

Nesting software

1). a variety of parts import method

2). fast conversion and file batch processing

3). efficient automatic layout function

2). fast conversion and file batch processing

3). efficient automatic layout function

Taiwan Taida Motor

Taiwan Shangyin Rail

YYC7 Grade Rack

Size Information

JX-6015 500W 1000W Fiber Laser Cutting Machine

|

Mainframe structure

|

Double drive gantry structure

|

|

|

Working table width

|

1525 mm

|

|

|

Working table length

|

6050 mm

|

|

|

Cutting steel plate thickness

|

Carbon steel≤16mm,Stainless steel≤8mm

|

|

|

X, Y axis drive mode

|

Imported precision rack and pinion (helical)

|

|

|

X-axis effective cutting range

|

1525 mm

|

|

|

Y-axis effective cutting range

|

6050 mm

|

|

|

X/Y axis maximum linkage positioning speed

|

100m/min

|

|

|

X, Y axis maximum acceleration

|

1.1G

|

|

|

Power Parameters

|

|

|

|

Phase No.

|

3

|

|

|

Power supply rated voltage

|

380V

|

|

|

Frequency

|

50Hz

|

|

|

Total power protection level

|

IP54

|

|

|

Weight and size

|

|

|

|

Worktable maximum load

|

1500kg

|

|

|

Machine weight

|

3800Kg

|

|

|

Dimension(length×width×height)

|

6600mm×2450mm×2230mm

|

|

|

Remark

|

Cutting area can be customized as per clients.

|

|

Cutting Data Reference for Optical Fiber Laser Cutting Machine

|

Power

|

Carbon steel plate

|

Stainless steel plate

|

Copper

|

Aluminium

|

Red copper

|

|

300W

|

0.5-3mm

|

0.5-1.5mm

|

|

|

|

|

500W

|

0.5-6mm

|

0.5-3mm

|

|

|

|

|

750W

|

0.5-8mm

|

0.5-4mm

|

|

|

|

|

1000W

|

0.5-12mm

|

0.5-6mm

|

1-3mm

|

1-3mm

|

1-2mm

|

|

1500W

|

1-16mm

|

0.5-8mm

|

1-5mm

|

1-6mm

|

1-2mm

|

|

2000W

|

1-16mm

|

1-8mm

|

1-5mm

|

1-8mm

|

1-3mm

|

|

3000W

|

1-20mm

|

1-10mm

|

1-6mm

|

1-8mm

|

1-4mm

|

|

4000W

|

1-20mm

|

1-12mm

|

1-8mm

|

1-10mm

|

1-5mm

|

|

6000W

|

1-25mm

|

1-14mm

|

1-8mm

|

1-12mm

|

1-6mm

|

Working pictures

The fiber laser cutting machine focuses the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach

the melting point or boiling point, while the high-pressure gas coaxial with the beam blows away the molten or vaporized metal.

As the relative position of the beam and the workpiece moves, the material will finally form a slit, so as to achieve the purpose of cutting. Laser cutting processing is to replace the traditional mechanical knife with an invisible beam. It has

the characteristics of high precision, fast cutting, not limited to the cutting pattern, automatic typesetting, saving materials, smooth cutting, and low processing cost. It will be gradually improved or replaced.

Traditional metal cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece, and will not scratch the surface of the workpiece during work; the laser cutting speed is fast, the incision is smooth and flat, and generally does not need subsequent processing; the cutting heat affected zone is small, the plate deformation is small, and the slit is narrow ( 0.1mm~0.3mm); the incision has no mechanical stress, no shearing burr; high processing accuracy, good repeatability, and no damage to the surface of the material; CNC programming, can process any plan, and can cut large-format whole plates without Opening the mold saves time and economy.

The laser cutting machine focuses the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, while the high-pressure gas coaxial with the beam blows away the molten or vaporized metal.

As the relative position of the beam and the workpiece moves, the material will finally form a slit, so as to achieve the purpose of cutting.

Cutting Sample

Related Products

Packing&Shipping

One machine picked in 2 or 3 wooden cases. Shipped by sea by LCL, or by truck, by air.

Company Introduction

Shandong Jiaxin Machinery Equipment Co.,Ltd.located in the hometown of Confucius and Mencius-Jining City, northwest of excellent transport location for communication between business and customers to provide a great convenience and fast.

Science and technology are primary productive forces"continuous advancement of technology is the development of the eternal source of power. The factory after nearly 20 years of development from a roller mold factory into a large-scale production of cold. Hot-rolled steel processing equipment. CNC steel processing equipment five series more than thirty kinds of products manufacturer enterprises.

We have always adhered to the "integrity of management, quality first” business philosophy; customer for Gud's business objectives. Through a nationwide sales and service network, improve the pre-sale, selling service and after sale service; sincere cooperation by providing quality products and efficient service for you.

Our Services & Strength

1.Pre-Sales Service:

1)Inquiry and consulting support.

2)We provide you the friendly English user manual and testing video free.

3)24 hours technical support by email or calling.

2.After-Sales Service:

1)Video of operating the machine are available.

2)12 months warranty quality guarantee and charge free technical support forever.

3)Free training to make sure you master the operating of machine.

FAQ

Q: What's the delivery time?

A: 10-15 working days to delivery port.

Q: What's the usually delivery terms?

A: FOB, CNF, CIF, Exworks will be OK.

Q: What's the MOQ?

A: 1 set.

Q: What’s the payment term?

A: We accept T/T, L/C or Cash.

Q: What's your delivery port?

A: Usually Qingdao port, Shanghai port.

Q: What's the packing?

A: Iron Pallet and Plywood cases or carton or depending on your requires.

Q: Can I change the motor to my local voltage and frequency, Is thereany extra charge?

A: Yes, we can supply motor with frequency and voltage according to local standard. Such as 220V/380V/410V/415V/440V, and 50HZ/60HZ without extra charge.

Q: Can you place OEM orders?

A: Yes,OEM orders are acceptable. We can manufacture machines according to your requirement with your design,logo,color,materials or brand information.

Q:Where is your factory located? How can I visit there?

A:Our factory is located in Jining City, Shandong Province, China, about 2 hours from Beijing, 3 hours from Shanghai.

Hot Searches