- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.2%

-

CrO Content (%):

-

0.2%

-

SiC Content (%):

-

98%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

sic

-

Brand Name:

-

XINLI

-

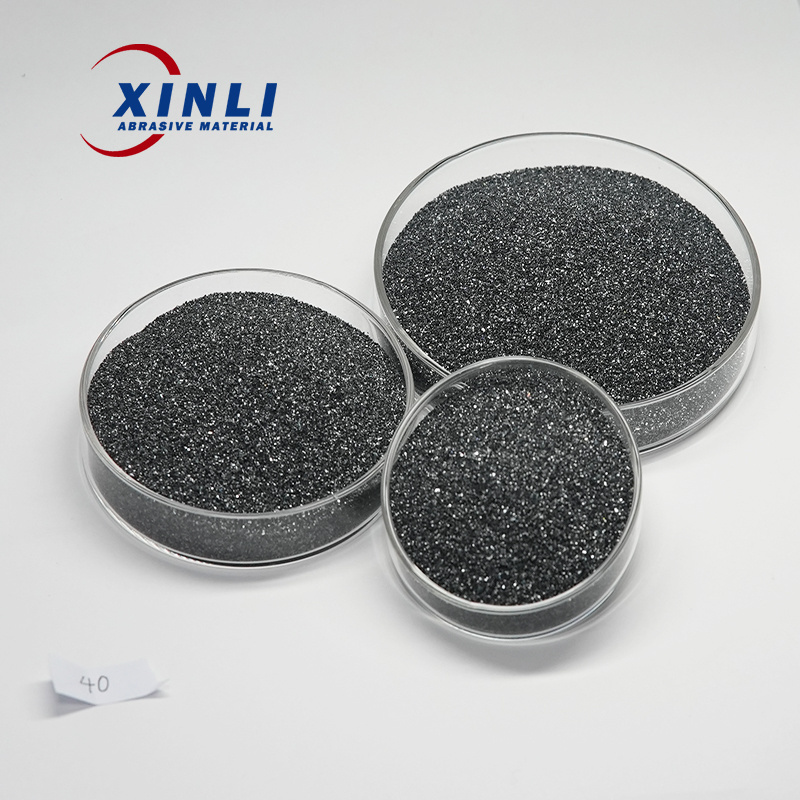

Abrasive Grain Sizes:

-

Sic 12-2000#

-

Usage:

-

Sand blasting, polishing, resin bonded

-

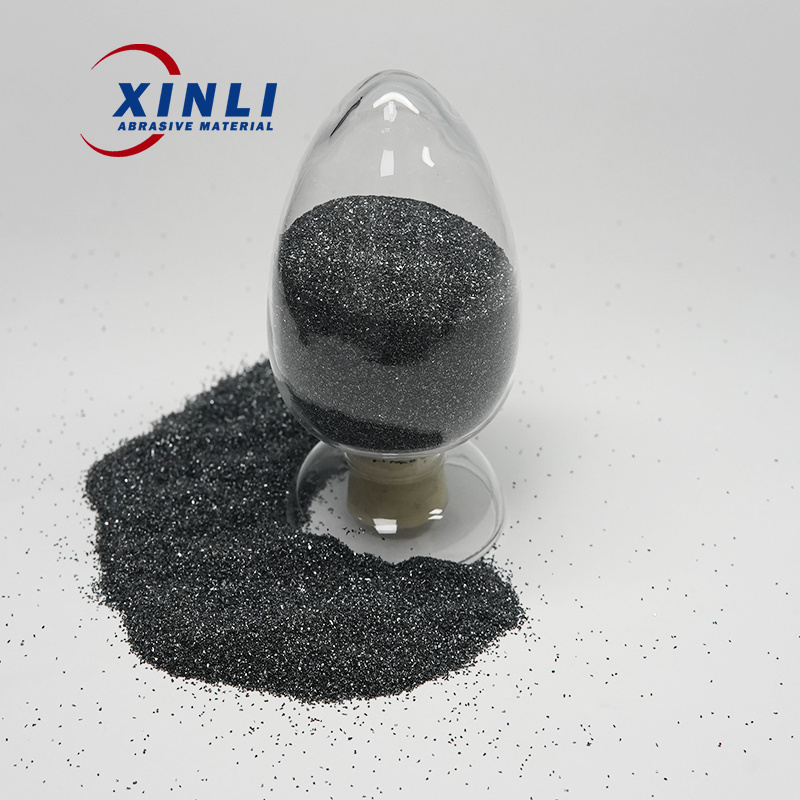

Color:

-

Black

-

SiC Content:

-

98.5% Min

-

Bulk density:

-

1.45-1.56g/cm3

-

Ture density:

-

3.12 g/cm3

-

Crystalsystem:

-

Hexagonal

-

Micro Hardness:

-

HV3100-3280

-

Certification:

-

ISO9001

Quick Details

-

SiO2 Content (%):

-

0.3%

-

Al2O3 Content (%):

-

0.3%

-

MgO Content (%):

-

0.15%

-

CaO Content (%):

-

0.2%

-

CrO Content (%):

-

0.2%

-

SiC Content (%):

-

98%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

sic

-

Brand Name:

-

XINLI

-

Abrasive Grain Sizes:

-

Sic 12-2000#

-

Usage:

-

Sand blasting, polishing, resin bonded

-

Color:

-

Black

-

SiC Content:

-

98.5% Min

-

Bulk density:

-

1.45-1.56g/cm3

-

Ture density:

-

3.12 g/cm3

-

Crystalsystem:

-

Hexagonal

-

Micro Hardness:

-

HV3100-3280

-

Certification:

-

ISO9001

1. Black Silicon Carbide Introduction

Because of the rarity of natural moissanite, most silicon carbide is synthetic. It is used as an abrasive, and more recently as a semiconductor and diamond simulant of gem quality. The simplest manufacturing process is to combine silica sand and carbon in an Acheson graphite electric resistance furnace at a high temperature, between 1,600 °C (2,910 °F) and 2,500 °C (4,530 °F). Fine SiO2 particles in plant material (e.g. rice husks) can be converted to SiC by heating in the excess carbon from the organic material. The silica fume, which is a byproduct of producing silicon metal and ferrosilicon alloys, also can be converted to SiC by heating with graphite at 1,500 °C (2,730 °F).

2. Black Silicon Carbide Chemical Composition (%)

| Grit | Sic | F.C. | Fe 2 O 3 |

| F12-F90 | ≥98.50 | <0.20 | ≤0.60 |

| F100-F150 | ≥98.00 | <0.30 | ≤0.80 |

| F180-F220 | ≥97.00 | <0.30 | ≤1.20 |

| F230-F400 | ≥96.00 | <0.40 | ≤1.20 |

| F500-F800 | ≥95.00 | <0.40 | ≤1.20 |

| F1000-F1200 | ≥93.00 | <0.50 | ≤1.20 |

| P12-P90 | ≥98.50 | <0.20 | ≤0.60 |

| P100-P150 | ≥98.00 | <0.30 | ≤0.80 |

| P180-P220 | ≥97.00 | <0.30 | ≤1.20 |

| P230-P500 | ≥96.00 | <0.40 | ≤1.20 |

| P600-P1500 | ≥95.00 | <0.40 | ≤1.20 |

| P2000-P2500 | ≥93.00 | <0.50 | ≤1.20 |

3. Black Silicon Carbide Physical Index

| Grits |

Bulk Density

g/cm 3 |

High Density

g/cm 3 |

Grits |

Bulk Density

g/cm 3 |

High Density

g/cm 3 |

| F16 ~ F24 | 1.42~1.50 | ≥1.50 | F100 | 1.36~1.45 | ≥1.45 |

| F30 ~ F40 | 1.42~1.50 | ≥1.50 | F120 | 1.34~1.43 | ≥1.43 |

| F46 ~ F54 | 1.43~1.51 | ≥1.51 | F150 | 1.32~1.41 | ≥1.41 |

| F60 ~ F70 | 1.40~1.48 | ≥1.48 | F180 | 1.31~1.40 | ≥1.40 |

| F80 | 1.38~1.46 | ≥1.46 | F220 | 1.31~1.40 | ≥1.40 |

| F90 | 1.38~1.45 | ≥1.45 |

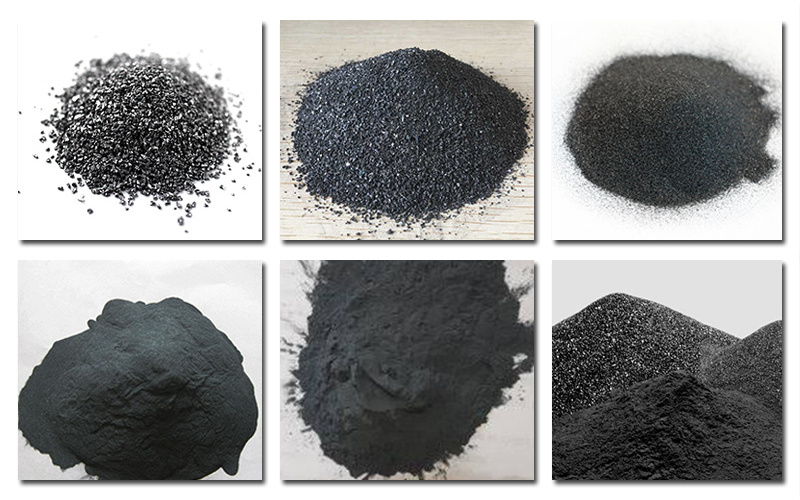

4. Black Silicon Carbide Size Available

F12-F1200, P12-P2500

0-1mm, 1-3mm, 6/10, 10/18, 200mesh, 325mesh

Other special specifications could be supplied on request.

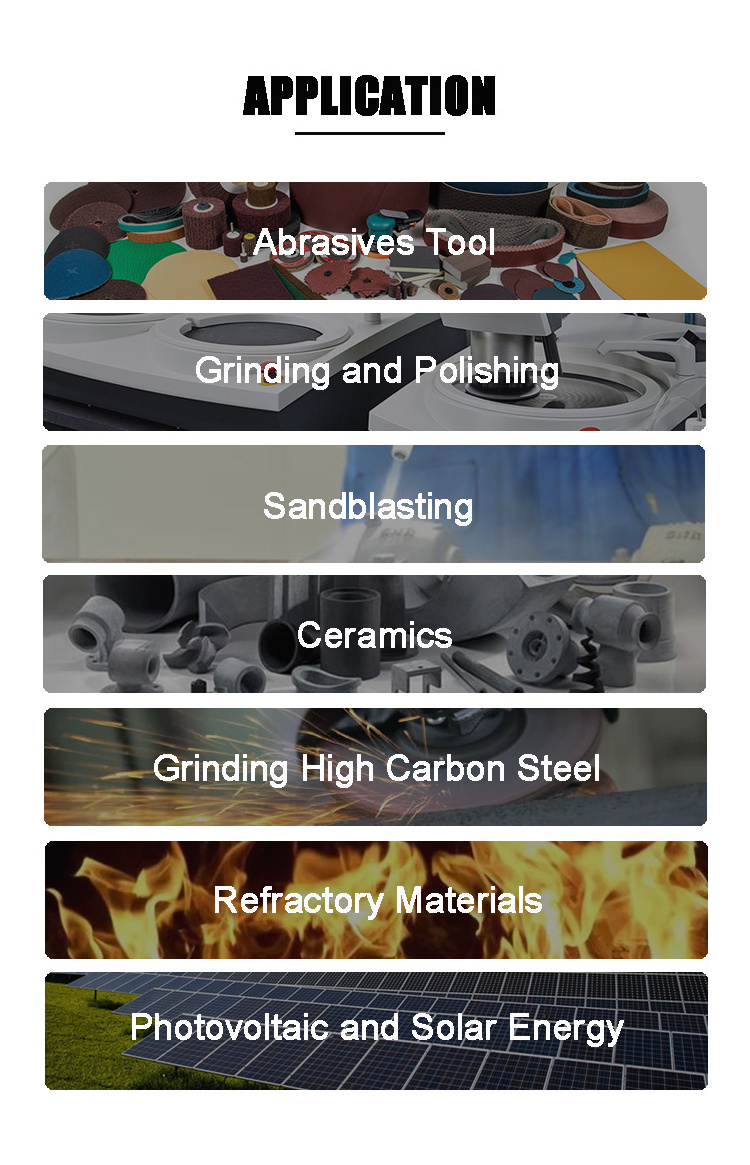

5. Black Silicon Carbide Applications

For abrasive: Lapping, Polishing , Coatings, Grinding , Pressure blasting.

For refractory: Refractory media for casting or metallurgical linings ,Technical Ceramics.

For new-type application: Heat exchangers ,Semiconductor process equipment , Liquid filtration.

6. Black Silicon Carbide acking

1. 25kg woven bag, 40 woven bags/jumbo bag.

2. 25kg woven bag, 40 woven bags/pallet

3. 25kg paper bag, 40 paper bags/pallet

4. 25kg paper bag, 40 paper bags/paper box