- Product Details

- {{item.text}}

Quick Details

-

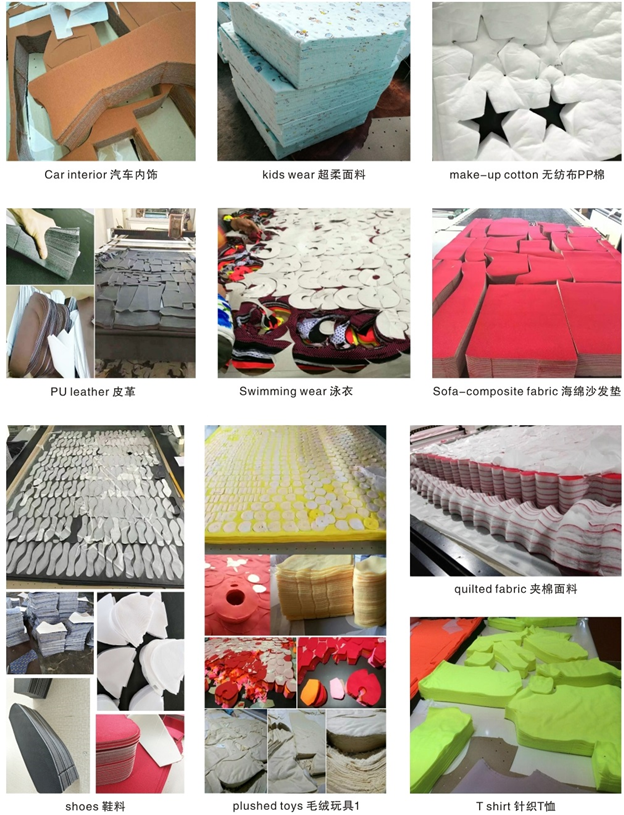

Application:

-

garment/cloth/textile/leather

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YINENG

-

Power:

-

24kw / 27kw / 32kw

-

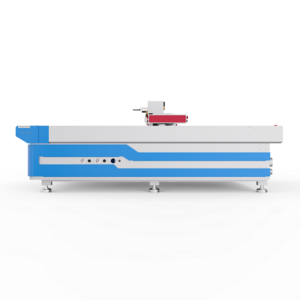

Dimension(L*W*H):

-

5760x2900x2500

-

Weight:

-

4500 KG

-

Features:

-

High Speed, Patented

-

Warranty:

-

One Year

-

Material Capabilities:

-

Polyester Fabric

-

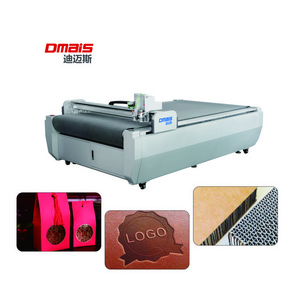

Type:

-

Hydraulic Fabric Press Machine

-

sharpen way:

-

double gear derogatory method

-

Standard Model sizes:

-

Customzied

-

Cutting thickness::

-

Max 80mm

-

Name:

-

Auto Cutter

-

Certification:

-

ISO

Quick Details

-

Production Capacity:

-

60m/min

-

Voltage:

-

380V/220V

-

Marketing Type:

-

Hot Product 2021

-

Application:

-

garment/cloth/textile/leather

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YINENG

-

Power:

-

24kw / 27kw / 32kw

-

Dimension(L*W*H):

-

5760x2900x2500

-

Weight:

-

4500 KG

-

Features:

-

High Speed, Patented

-

Warranty:

-

One Year

-

Material Capabilities:

-

Polyester Fabric

-

Type:

-

Hydraulic Fabric Press Machine

-

sharpen way:

-

double gear derogatory method

-

Standard Model sizes:

-

Customzied

-

Cutting thickness::

-

Max 80mm

-

Name:

-

Auto Cutter

-

Certification:

-

ISO

|

Model No.

|

KP-X1725

|

KP-X2025

|

KP-X2325

|

KP-X1733

|

KP-X2033

|

KP-X2333

|

|||||

|

Cutting area

|

1700*2500

|

2000*2500

|

2300*2500

|

1700*3300

|

2000*3300

|

2300*3300

|

|||||

|

|

63"*98"

|

75"*98"

|

87"*98"

|

63"*130"

|

75"*130"

|

87"*130"

|

|||||

|

Cutting thickness

|

Max.70mm

|

|

|

|

|

|

|||||

|

Cutting materials

|

Garment cloth(knitted and woven),nonwoven fabric, plush toys, shoes, leather,sofa cushion,car interior decorative fabric, bras, medical gause, composite fabric, car seat,ect.

|

|

|

|

|

|

|||||

|

Max cutting speed

|

60m/min(according cutting materials)

|

|

|

|

|

|

|||||

|

Cutting accuracy

|

≤±1mm

|

|

|

|

|

|

|||||

|

Power

|

30KW

|

|

|

|

|

|

|||||

|

Max speed

|

4000rpm/min

|

|

|

|

|

|

|||||

|

Cutting style

|

Straight Knife Continous Up-down Cutting

|

|

|

|

|

|

|||||

|

Cooling System

|

Auto Air Cooling System

|

|

|

|

|

|

|||||

|

Control System

|

KP-ACS Copyright system well compatibility with any version CAD software

|

|

|

|

|

|

|||||

|

Software

|

Multi-language ACS software,auto change

|

|

|

|

|

|

|||||

|

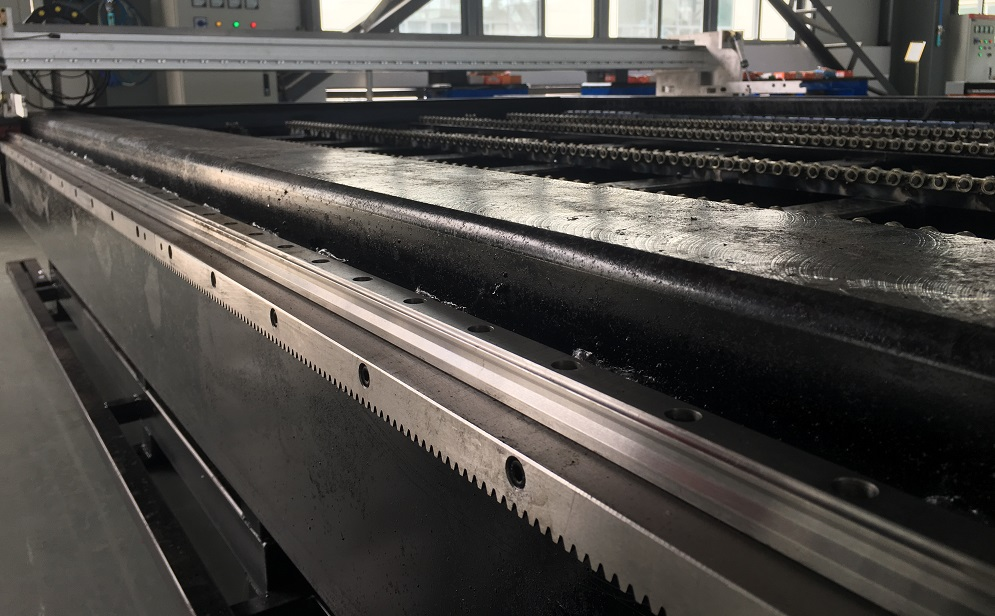

Sharpen way

|

double gear derogatory method

|

|

|

|

|

|

|||||

|

Air pressure supply

|

7KPS

|

|

|

|

|

|

|||||

|

Motor/driver

|

apanese Panosonic Servo motors&Drivers

|

|

|

|

|

|

|||||

|

Machine power

|

AC380V/50HZ

|

|

|

|

|

|

|||||

|

Weight(kgs)

|

3300

|

3500

|

3700

|

3700

|

3900

|

4100

|

|||||

|

Machine out size(mm)

|

5900*2650*1500

|

5900*2950*1500

|

5900*3250*1500

|

7500*2650*1500

|

7500*2950*1500

|

7500*3250*1500

|

|||||

1.The machine body is whole body with full welding.

2.machine body is been milled by the Large five-axis milling machine with one time fine milling.

3.The machine body adopt the advance steel plate seamless connection of square box with high-speed machine bed structure

developed by us, we own its copy right, it can accept 98% cloth CAD software and different file format PLT, DXF, CUT,TAC and so on.

cutting.

- Packaging Details : Cutting Machine with water-proof film and standard wooden case

- Port : Shanghai, Shenzhen

- Lead Time : within 30 working daya after deposit

A.Free sample making: For free sample making/testing, please send your samples or products CAD Graphics to our company in China.Try before you buy.

B. Progressing solution design

One-year after-sales service includes:

A. We will offer some of the parts for free in the first year.

B. In the first year, if the buyer needs our engineers to come to the local to fix some problems of

the machine that they cannot fix by themselves; we will send our engineers for free. The buyer needs to pay the flights,

housing and meals for the engineers in the local.

C. We will offer our service through email and phones and online service if the buyer needs any help

on technical problems.

3. Installation and technical training includes:

We will send our engineers to customer’s factory for the local training and the installation, and this is free. The buyer needs to pay hotel and meals for the engineers in the local.

In-time golden services

A. Parts supply intime

we produce on order, Parts in warehouse for over 30 sets to guarantee the delivery of order and maintenance.

B. Release clients worry about big equipment service; supply the part with bare cost.

Standardized service management system, including: customer contact management, customer troubleshooting management, customer equipment regular maintenance, inspections management, customer records management and other accessories reviews.

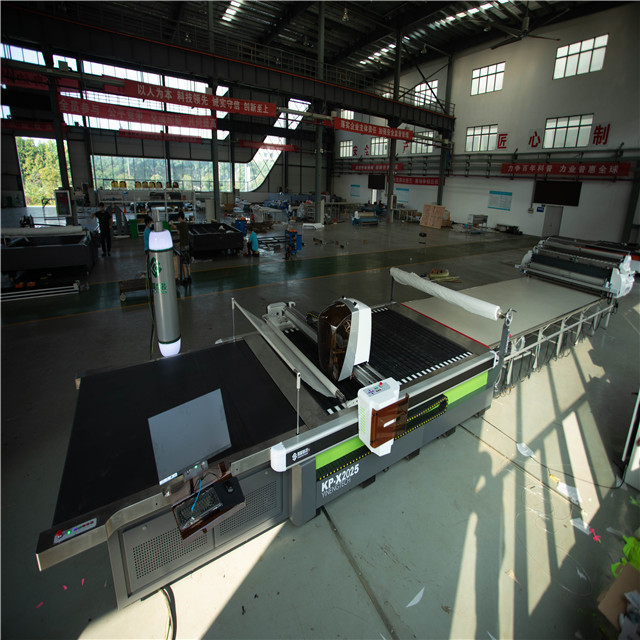

Wuhan King Suntime CNC Equipment Co., LTD is established in 2002, we are professional in reaching, manufacturing full set of automatic cutting system, the production include automatic multiply fabric cutting machine & Mono layer cutter &spreading machine. We are striving to provide you the machine based on our several years of practical production experience.

Our main product is automatic fabric cutter, the sales volume has reached the top five in the world till 2007, we will try our best to reach top 3 in future 3years.

Now our whole heart is commted to solve the cutting system for all kinds of software materials, to make it intelligent, simplicity and worldwide.