- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

nitinol tube

-

Material:

-

nickel titanium alloy, nitinol, Nitinol Ti-Ni Alloy

-

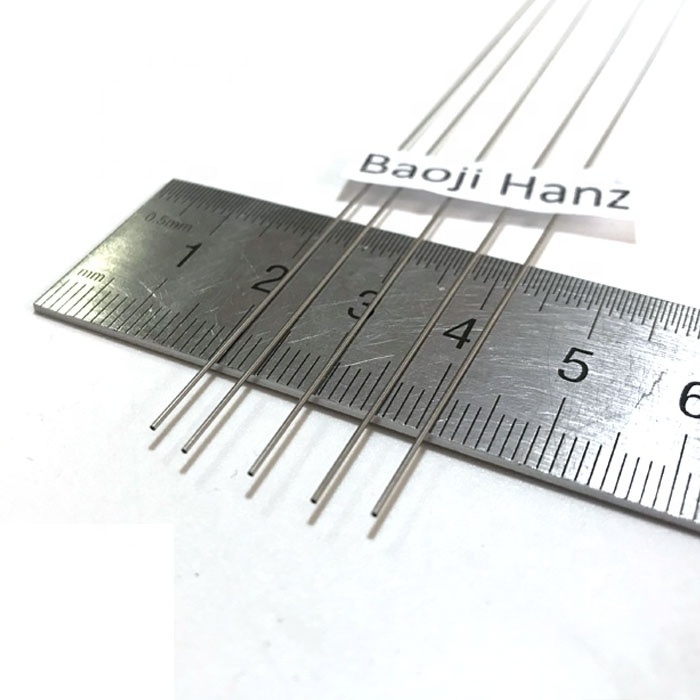

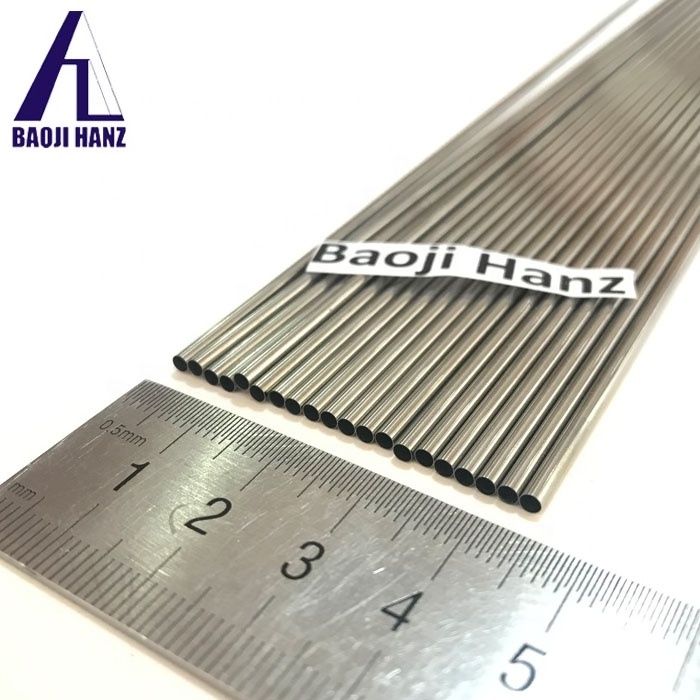

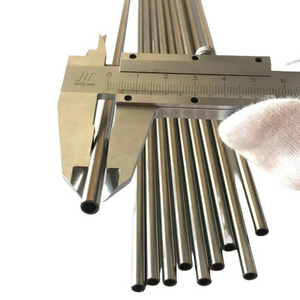

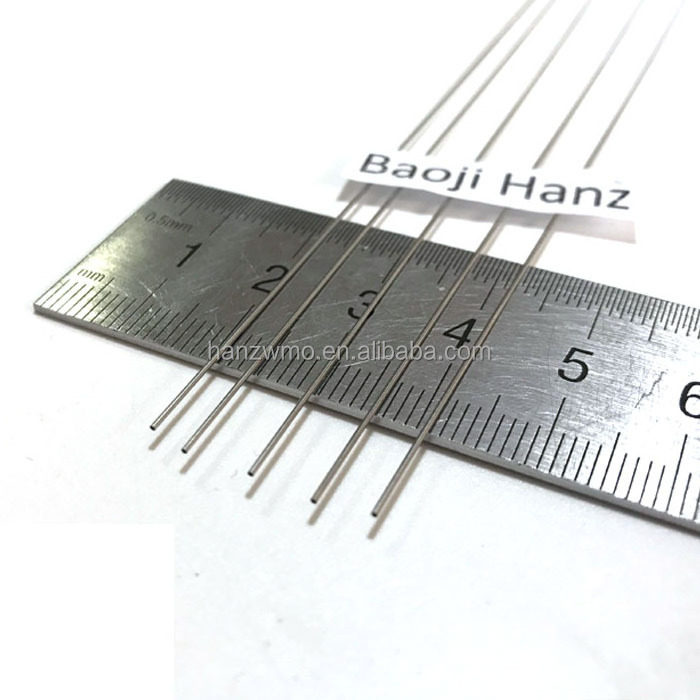

Outer Diameter:

-

3mm~114mm

-

Length:

-

≤6000mm

-

Application:

-

Chemical Industry medial

-

Grade:

-

nitinol., nickel titanium alloy

-

Wall Thickness:

-

0.1mm~15mm

-

Inside Diameter:

-

≥1.8mm

-

Product Name:

-

Buy confluent cut nitinol capillary tube from China

-

MOQ:

-

3 METERS

-

Shape:

-

CURVED

-

Nickel:

-

55-57%

-

CERTIFICATION:

-

ISO9001:2008

-

Advantage:

-

Excellent Corrosion Resistance

-

Feature:

-

Shape memory, superelastic

-

Surface Treatment:

-

Polishing Brushing Acid-pickling

Quick Details

-

Standard:

-

ASTM F2063, ASTM F2633-07

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Baoji Hanz

-

Model Number:

-

nitinol tube

-

Material:

-

nickel titanium alloy, nitinol, Nitinol Ti-Ni Alloy

-

Outer Diameter:

-

3mm~114mm

-

Length:

-

≤6000mm

-

Application:

-

Chemical Industry medial

-

Grade:

-

nitinol., nickel titanium alloy

-

Wall Thickness:

-

0.1mm~15mm

-

Inside Diameter:

-

≥1.8mm

-

Product Name:

-

Buy confluent cut nitinol capillary tube from China

-

MOQ:

-

3 METERS

-

Shape:

-

CURVED

-

Nickel:

-

55-57%

-

CERTIFICATION:

-

ISO9001:2008

-

Advantage:

-

Excellent Corrosion Resistance

-

Feature:

-

Shape memory, superelastic

-

Surface Treatment:

-

Polishing Brushing Acid-pickling

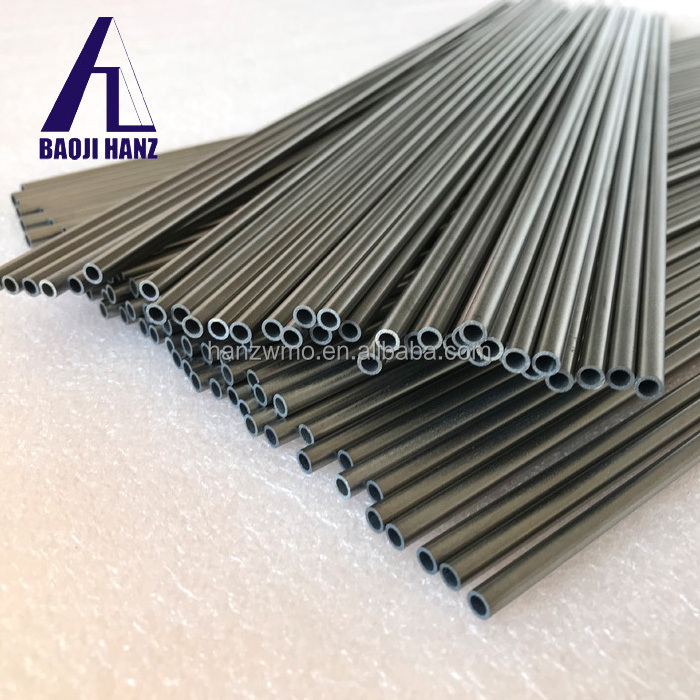

Buy confluent cut nitinol capillary tube from China

Buy confluent cut nitinol capillary tube from China

1. Basic information Of Nitinol shaple memory nitinol alloys tubes manufacturer

1,Nitinol alloy tube

2,Standards: ASTM, ASTM F2633-07

3,high-precision

4,Deep hole working

5,Large diameter and thin wall

6,Outside diameter: Max=300mm, Min=20mm

7,Thickness: ≥ 0.08mm(machined )

Length: ≤1000mm(determined by outside diameter and thickness)

Surface: Ra( inside≤1.2μm, outside≤0.6μm)

9,Typical Applications:shell of Oil well logging,sports,power,automotive components,marine corrosin,chemical plant

10,Technique: Seamless or Welding

Superelastic nitinol pipe shape memory tube medical use

2.Surface State Options for nitinol tube

♣ Black oxide surface

♣ As cleaned surface

♣ Medical grade polished surface

♣ Centerless ground surface

Superelastic nitinol pipe shape memory tube medical use

3. Chemical composition nitinol

Ni: 55.4% --56.2% C≤0.07 H≤0.005 O≤0.050 N:≤ 0.05

Superelastic nitinol pipe shape memory tube medical use

4.Standard for nitinol

ASTM F2063-05 Q/XB1516 Customer specified or Industry Standard

|

Alloy |

Chemical composition |

Af (Fully annealed) |

Min. elongation to failure [%] |

Max. Residual elongation after 6% strain [%] |

Main Applications |

|

|

Superelastic Ni-Ti alloy |

TiNi-SS |

Ti-50.8at% |

-5°C ± 5°C. |

10 |

0.1 |

Eyeglass Frames, Cellular Phone Antennae, Bra Underwire |

|

TN3 TNC |

TiNiVAl TiNiCr |

-40°C ~50°C |

10 |

0.1 |

||

|

Body temperature Ni-Ti alloy |

TiNi-YY |

Ti-50.7at%Ni |

Functional Af=33 ± 3 |

15 |

0.1 |

Implantable devices,Bone staples Vascular Stents |

|

Ti-Ni-01 |

55.6~55.8 wt%Ni |

20 - 40 |

15 |

0.1 |

Guide wires, Stents Orthodontic Arches |

|

|

High temperature Ni-Ti alloy |

Ti-Ni-02 |

54.8~55.5wt%Ni |

45 - 95 |

10 |

0.1 |

Implantable active devices, Surgical tools, Thermostats Coffeepots |

|

TiNiCu |

TiNiCu |

As-Ms ≤ 5 |

10 |

0.1 |

||

5. Application of nitinol

Chemical Composition:

|

|

||||||||||||||||||||||

Mechanical / Superelastic Tubes Properties:

Note: The Mechanical / Superelastic Properties are only for orientation and can be changed if necessary. |

|||||||||||||||||||||||

Physical Tube Properties:

|