Medium Frequency Induction Furnace(Aluminum Shell)

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Not standard

-

Weight (T):

-

1 T

-

Power (kW):

-

600

-

Applicable Industries:

-

Metal Process

-

Keyword:

-

Induction melting furnace

-

Capacity:

-

1T 1000kg

-

After-sales Service Provided:

-

Yes

-

Application:

-

Melting Metal

-

Max temperature:

-

500C - 2300C (custom Made)

-

Melting Material:

-

Aluminum Gold Silver Copper Brass Bronze

-

Melting Time:

-

50 Minutes

-

Frequency:

-

1000HZ

-

Cabinet:

-

Yes

-

Cooling tower:

-

Available

Quick Details

-

Place of Origin:

-

China

-

Core Components:

-

Electric Components

-

Brand Name:

-

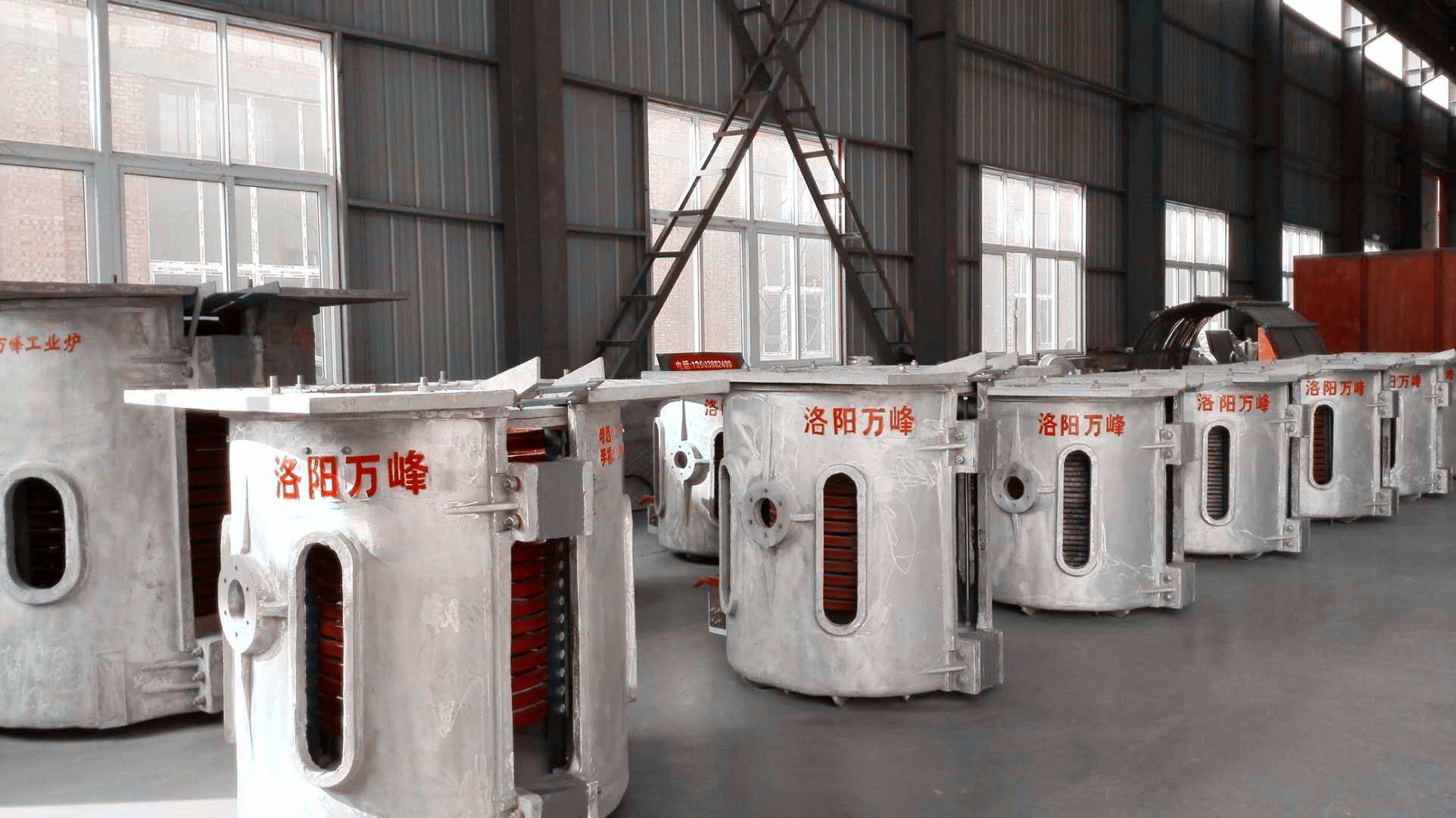

WANFENG

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Not standard

-

Weight (T):

-

1 T

-

Power (kW):

-

600

-

Applicable Industries:

-

Metal Process

-

Keyword:

-

Induction melting furnace

-

Capacity:

-

1T 1000kg

-

After-sales Service Provided:

-

Yes

-

Application:

-

Melting Metal

-

Max temperature:

-

500C - 2300C (custom Made)

-

Melting Material:

-

Aluminum Gold Silver Copper Brass Bronze

-

Melting Time:

-

50 Minutes

-

Frequency:

-

1000HZ

-

Cabinet:

-

Yes

-

Cooling tower:

-

Available

Product Description

We are a factory, we can produce

20KG-20T

Metal Smelting Furnace.

Medium Frequency Induction Furnace Mainly is used for

melting steel, iron, copper, aluminum,zinc,lead and alloy,etc.

The induction melting furnace has good electromagnetic stirring and melting metal is conducive to uniform temperature.

Technological Process

Casting Production Line

1.Metal Scrap---2.Melting Furnace---3.Casting Machine---4.Finished Product

Product Details

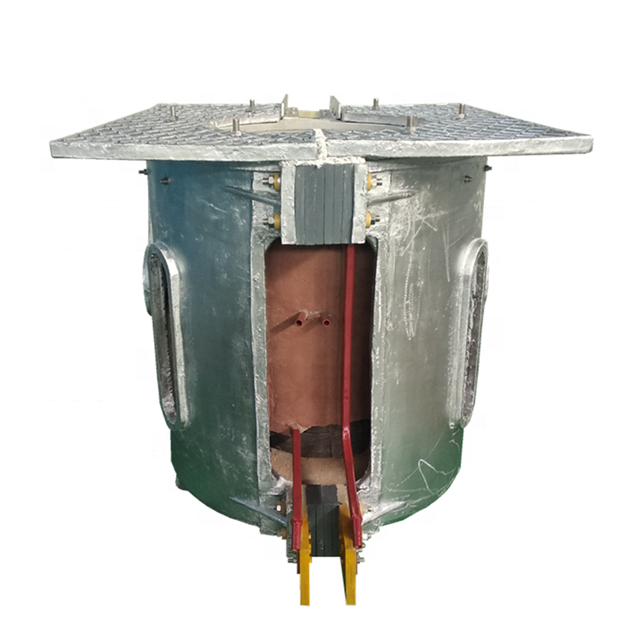

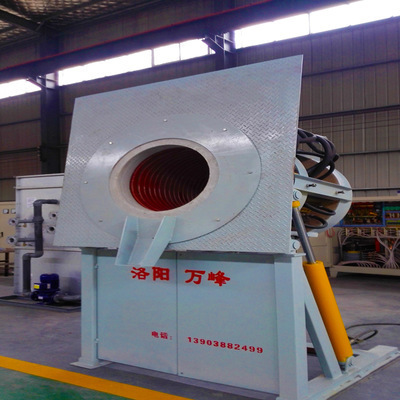

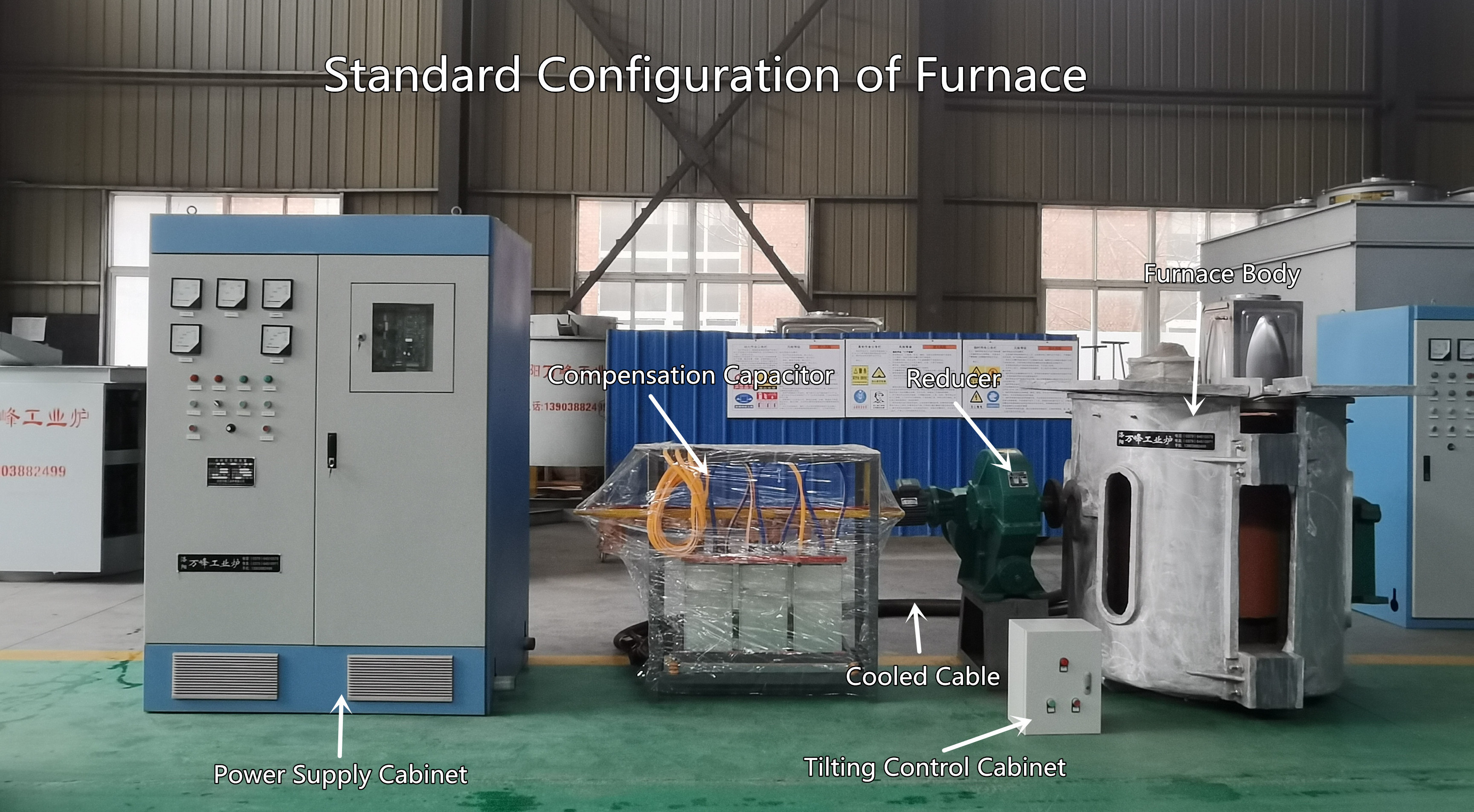

Furnace Body

---------------------------------------

1. The furnace body of Wanfeng induction furnace is made of aluminum alloy, and

the inductor outer layer is wrapped with refractory cement, protect the inductor, more durable, not easy to wear furnace. There is insulation board between the upper layer of inductor and asbestos board as support and protection, asbestos board is not easy to break and crack, reduce loss.

2.

The induction coil is made of thick wall oxygen free extruded copper tube. After multilayer insulation treatment, it has high strength and large current carrying capacity.

Induction Coil

Crucible Mold

Cooled Cable

Power Supply C

abinet

----------------------------------------

1.

Electronic components are well-known brands at home and abroad, stable operation, superior performance.

2.Built in water temperature alarm, water pressure alarm, phase failure alarm, leakage protection and other early warning systems.

3.All the components of the intermediate frequency power supply adopt scientific and reasonable patent structure layout, which greatly reduces the electromagnetic vibration and noise of the equipment and effectively reduces the electromagnetic interference.

Melting Management System

of

Power Supply Cabinet

----------------------------------------------------------------

Melting Management System

The melting management control system mainly monitors the operation of intermediate frequency furnace system online. The system integrates data acquisition and adjustment, waterway inspection, temperature control, remote diagnosis and other functions, and isolates the control function and status information from the main equipment, which is convenient and safe.

Data collection and adjustment: directly collect voltage, current, frequency and other electrical parameters of each link, display and save in real time, customers can realize remote control operation through remote control cabinet.

-------------------------------------------------------------------------------------------------

1.Waterway inspection:

monitor the cooling water temperature of variable frequency cabinet and furnace body to avoid burning of electrical parts.

2.Temperature control: PID temperature control system, real-time sensitive adjustment of melting temperature.

3.Remote diagnosis: For the operation state of the intermediate frequency furnace system, data retention and analysis are carried out in the "company headquarters" through the "Internet of things" to realize the remote diagnosis function. When there is a failure and shutdown, it can be dealt with in the first time.

2.Temperature control: PID temperature control system, real-time sensitive adjustment of melting temperature.

3.Remote diagnosis: For the operation state of the intermediate frequency furnace system, data retention and analysis are carried out in the "company headquarters" through the "Internet of things" to realize the remote diagnosis function. When there is a failure and shutdown, it can be dealt with in the first time.

Must-read!

Capacitor Compensation Cabinet

----------------------------------------

1.

Used to compensate the inductive reactive power of the induction furnace, the intermediate frequency power cabinet only needs to transmit the active power, which greatly reduces the capacity and cost of the inverter.

2. All electrical joints of intermediate frequency power supply and capacitor cabinet are made of tin plating technology, which is

not easy to oxidize and has low contact resistance, thus reducing heat of joints and improving electrical efficiency.

----------------------------------------

Furnace Tilting Reducer is used to control the rotary of the furnace body.The tilting reducer is equipped with three-stage turbine speed. With good self-locking and stable rotary performance.

Parameters

|

|

Rated capacity

|

Rated power(KW)

|

Rated frequency(Hz)

|

Input voltage(V)

|

|

Steel

Melting

Furnace

|

100kg

|

100

|

2500

|

3 phase, 50Hz,380V

|

|

|

150kg

|

160

|

1000

|

|

|

|

250kg

|

250

|

|

|

|

|

500kg

|

400

|

|

|

|

|

750kg

|

500

|

|

|

|

|

1T

|

1000

|

|

|

|

|

2T

|

1400

|

700

|

|

|

|

3T

|

2000

|

500

|

|

|

|

5T

|

2500

|

|

|

|

|

8T

|

4000

|

|

6 phase,50Hz,850V

|

|

Aluminum

Melting

Furnace

|

150kg

|

100

|

1000

|

|

|

|

300kg

|

200

|

|

|

|

|

500kg

|

300

|

|

|

|

|

750kg

|

400

|

|

|

|

|

1T

|

600

|

|

|

|

|

1.5T

|

750

|

700

|

6phase, 50Hz,380V

|

|

|

3T

|

1800

|

500

|

6phase, 50Hz,1000V

|

|

|

5T

|

2500

|

300

|

|

|

Copper

Melting

Furnace

|

150kg

|

100

|

|

3 phase, 50Hz,380V

|

|

|

250kg

|

160

|

|

|

|

|

350kg

|

160

|

|

|

|

|

500kg

|

300

|

|

|

|

|

750kg

|

400

|

|

|

|

|

1T

|

600

|

1000

|

3 phase, 50Hz,380V

|

|

|

2T

|

1000

|

700

|

6 phase, 50Hz,750V

|

|

|

3T

|

1600

|

500

|

750V/1000V

|

|

|

5T

|

2000

|

300

|

|

Customer Support

Customer Site Case

---------------------------------------------

Customer Visit

-------------------------------

Customer Praise

---------------------------------

Recommend Products

Why Choose Us

Rich

in 28 years manufacture

experience

Reliable

on 10 years exporting

experience

Reassuring

at turnkey project and 24hr

online support

Our Advantages

---------------------------------

Packing & Delivery

--------------------------------------

24H Customer Service

Online Service

Vedio Call Service

Oversea Service

Contact Us:

*Contacts

:

Marcia Xu

*

TEL/Whatsapp/Wechat:

+86 18039411986

*Email:

yorkzhang@wanf.cn

*Address:

The southern tip of Jianxi Industrial Park. Jianxi District, Luoyang, China

Hot Searches