- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Gyeonggi-do, South Korea

-

Brand Name:

-

Sunny Warm

-

Model Number:

-

SW-305Te, SW-305Me, SW-3065Te, SW-306Me

-

Using Voltage:

-

AC220V~230V

-

Thinkness:

-

0.338mm

-

Color:

-

Milky White(Flameproof PET), Transparent

-

Width:

-

50cm, 60cm

-

Certificates:

-

CE, RoHS, TUV, UKCA, EAC

-

Power Consumption:

-

220watt/square meter

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Return and Replacement, Other

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Gyeonggi-do, South Korea

-

Brand Name:

-

Sunny Warm

-

Model Number:

-

SW-305Te, SW-305Me, SW-3065Te, SW-306Me

-

Using Voltage:

-

AC220V~230V

-

Thinkness:

-

0.338mm

-

Color:

-

Milky White(Flameproof PET), Transparent

-

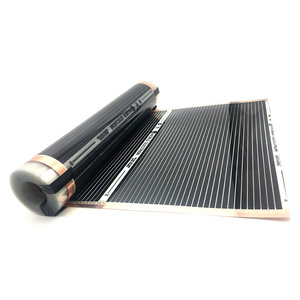

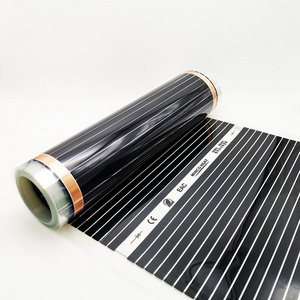

Width:

-

50cm, 60cm

-

Certificates:

-

CE, RoHS, TUV, UKCA, EAC

-

Power Consumption:

-

220watt/square meter

Smart & Intelligent PTC Heating Film!

Towtech Sunny Warm!

General Information

|

HS Code |

3921.90.6020 or 8545.90.9000 or 8516.29.0000 |

|

Order Unit |

1 roll (150m, 130m, 100m, 70m) |

|

Minimum Order Quantity |

SW30DC Series (Low Voltage Using) : 1,500meters (10rolls) SW300T / SW300M Series : 3,000meters SW400 Series : 5,000meters SW500 Series, SW600 Series : 10,000meters |

|

Daily Producing Quantity |

300 rolls per a day |

|

Certifications |

UL(cRus), CE, GOST, RoHS, ISO9001 , ISO14001 |

|

Warranty Period |

3 years after purchasing |

|

Payment Terms |

T/T, Irrevocable L/C, Money Gram Western Union, Pay Pal |

|

Basic Price Terms |

F.O.B. Busan Port / Incheon Airport, Korea |

|

Shipment Period |

Shipment will be completed within 10 days After Balance Payment |

|

Departing Port |

Busan Port or Incheon Port (Ocean Freight)

|

Towtech Sunny Warm!

Technology Generating Warmth!

Smart & Intelligent PTC Heating Film!

Towtech Co., Ltd., established in 2009, has developed a self-regulating PTC carbon paste first ever in Korea. In addition, Towtech Co., Ltd., has been manufacturing safer self-regulating PTC Sunny Warm heating films and electrostatic precipitation filters based on the latest production facilities and high-skilled experts.

Towtech Co., Ltd., has demonstrated its high-level technology complying to ISO9001, ISO14001 and to other overseas standards of electrical safety certification, such as CE, RoHS, TUV(NRTL), UKCA, EAC, etc.

With our technology and quality control, Towtech Co., Ltd., has been serving the clients in more than 20 countries including USA, Japan, UK, Poland, Norway, Germany and China. We are also striving to introduce Ondol which is Korean traditional floor heating system to the global partners.

Through our constant research, Towtech has been developing a variety of colors and designs in the manufacturing process of base film and Laminex film. We are now able to produce films of a variety of thickness by stacking layers of PET films with enhanced endurance.

Are you interested in electric heating materials?

Then, please consult with Towtech Co., Ltd.

We will make effort to become your successful business partner.

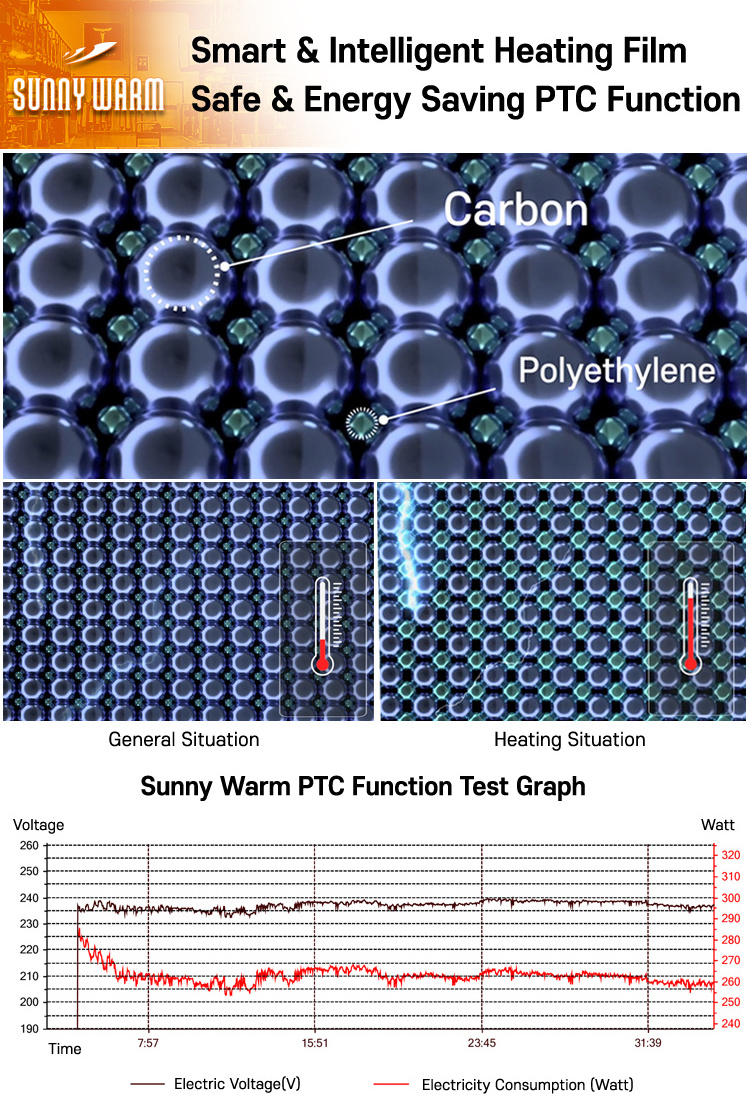

What is PTC function?

PTC is made from a carbon-nano compound, The compound is produced by incorporating carbon with polyethylene resin. In this case, carbon is used electrical conductor and polyethylene is used for its properties of contraction and expansion due to heat.

When the temperature goes up in one part of PTC heating film, the polyethylene resin expands. This increases PTC’s electric resistance then the power consumption is reduced.

So, PTC heating unit is very effective and safe to prevent any partial over-heating. It also generates more heat with low temperatures and reduces the power consumption as temperature goes up. It helps you to save energy.

Even in the same space, the temperature will vary according to the different conditions of lighting, humidity, and insulation.

But, as the whole part of PTC heating film self-controls the temperature, it keeps the optimal temperature by well-distributed heat with a minimum energy. Sunny Warm self-regulating PTC heating film helps your smart and intelligent heating. You now understand why this is the most effective electrical heating system.

How to choose a good heating film

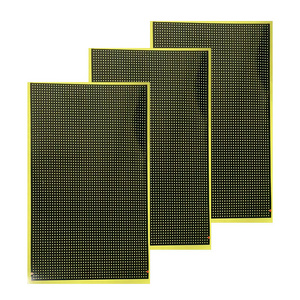

1. Carbon pattern for even heat distribution

2. Good adhesion between base film and Laminex film

3. Silver booth bar design that can deliver electricity evenly from copper foil to the carbon pattern

By reducing the thickness of the carbon paste print on the heating film and reducing the amount of silver paste to make a cheaper film, the difference in price can be US$0.30 at maximum.

However, thin carbon thickness and unstable silver booth bar can cause overheating of the heating film and cause a fire if such the heating film is used for a long time.

The carbon pattern is the same concept as the area of the heating element in heating film.

The even and wide carbon pattern means that heat is generated evenly over a large area in heating film and the heating efficiency is good.

However, if carbon is printed on the entire surface of the base film, the adhesive strength between the base film and Laminex film may be reduced. So, it is necessary to design a carbon pattern considering the adhesive strength of heating film.

The silver booth bar in the heating film is designed to stably supply electricity to the carbon pattern generating heat.

That is to say, the resistance values of carbon and copper foil are different. So, the silver booth bar with a low resistance value is printed on the carbon pattern in order to stably transfer the electricity transferred from the copper foil with a low resistance value to the carbon with a high resistance value.

Therefore, a good silver booth bar should have a concentration that makes the carbon pattern of the bottom invisible.

Also, the design of a good silver booth bar should have a straight line shape to evenly supply electricity to the carbon pattern.

In addition, if the silver booth bar is positioned on the carbon paste and the copper foil is placed at the same position, the rough surface of the copper foil can damage the silver booth bar and connected directly to carbon pattern cause an electrical spark. So, the ideal silver booth bar design is that carbon pattern and the copper foil are connected by the silver booth bar at a distance from each other.

Features of SUNNY WARM Heating Film

Energy Saving Effect

Prevention of Electromagnetic Wave

Antibacterial Effect

Deodorizing Effect

Far-infrared ray Emission

Overheating & Fire Prevention

SW30DC Series (DC Using & Sauna Film)

SW305T(e) is the sauna film which uses AC 220 voltage.

SW300T Series / SW300M Series

SW400 Series (Color PET & Color Laminex)

SW500 Series (Color PET & Color Laminex)

SW600 Series (Color PET & Non-Woven Fabric & Color Laminex)

Installation Procedure of SUNNY WARM Heating Film

1. Clean up the floor of installation area

Clean up the base floor and remove dusts on base floor. If the floor is wet, it also removes moisture.

2. Cutting insulation pad & fixating

Cover the floor with insulation according to the shape of the floor. Fixate insulation pad on floor with tape.

3. Cutting heating film & fixating

Cut heating film according to the floor size and place on the fixed insulation pad.

When cutting heating film, apply cutting to the places where there is scissors shape.

Allow 10 ~ 20cm of space from the wall and minimum 1cm between each heating film.

Then, fixate heating Film on the insulation pad using tapes.

3. Cutting heating film & fixating

Cut heating film according to the floor size and place on the fixed insulation pad.

When cutting heating film, apply cutting to the places where there is scissors shape.

Allow 10 ~ 20cm of space from the wall and minimum 1cm between each heating film.

Then, fixate heating Film on the insulation pad using tapes.

4. Insulation treatment of heating film

The cut side of the heating film that does not connect electric wires is insulated with insulation tape or butyl tape. Butyl tape is a kind of insulating tape.

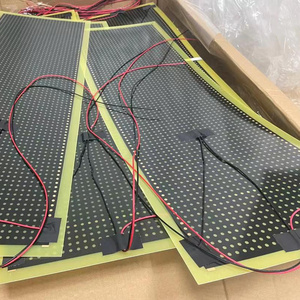

5. Connecting electric wires with terminals

Push a part of the pressure terminal on the copper foil part of the heating film into the empty space between the PET film and the laminex film and fix it firmly with a terminal presser."

Connect the electric wires in parallel to the terminals fixed on the heating film. Be careful not to twist the wires when connecting them.

6. Insulation treatment of electric wire connection area

Apply special insulation tape where the wire and film is connected.

When treat insulation, press the butyl tape strongly to prevent moisture from penetrating Organize electric wires using tapes.

7. Measurement of electric resistance & Calculation of electricity consumption

Measure total electric resistance of installed heating film with resistance tester.

Calculate the electricity consumption according to the formula.

8. Thermostat installation

Inspect connections of electric wire and circuit diagram of the installed heating film once again.

If there is no problem, connect the thermostat.

9. Check the temperature and Installation of finishing material

Turn on the power of thermostat ad, Check the surface temperature of heating film with infrared ray thermometer. If there are no problems, install the finishing material.

We are able to produce OEM products.

Possible to put buyers' brand and its logo in heating film

Possible to change PET and Laminex film color

Possible to manufacture special thickness or width of heating film

Possible to change carbon pattern

Possible to change silver booth bar position and width

Possible to change copper foil position and width

Possible to use tin coated copper foil

Possilbe to adjust electricity consumption per meter of heating film

Possible to make a heating film for special electric voltage such as; AC 380 voltage, DC(direct current) 5voltage, 12voltage, 24voltage and 48voltage etc.

Possible to supply pre-cut heating film according to the purpose of use

Possible to supply terminal connected heating film