- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

AZS Series

-

Brand Name:

-

RongSheng

-

Application:

-

Refractory Material

-

Bulk density:

-

3.8-5.2

-

Cold crushing strength(mpa):

-

350

-

ZrO2:

-

≥33%

-

Product name:

-

Zirconium Corundum Bricks

-

Raw material:

-

Zirconium Corundum

-

Usage:

-

Furnace Liner

-

Keyword:

-

Fused Cast AZS Blocks

-

Certificate:

-

CE ISO

-

Feature:

-

High Temperature Resistant

Quick Details

-

SiO2 Content (%):

-

0.3-15

-

Al2O3 Content (%):

-

≥80%

-

MgO Content (%):

-

0.8-1.2

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

AZS Series

-

Brand Name:

-

RongSheng

-

Application:

-

Refractory Material

-

Bulk density:

-

3.8-5.2

-

Cold crushing strength(mpa):

-

350

-

ZrO2:

-

≥33%

-

Product name:

-

Zirconium Corundum Bricks

-

Raw material:

-

Zirconium Corundum

-

Usage:

-

Furnace Liner

-

Keyword:

-

Fused Cast AZS Blocks

-

Certificate:

-

CE ISO

-

Feature:

-

High Temperature Resistant

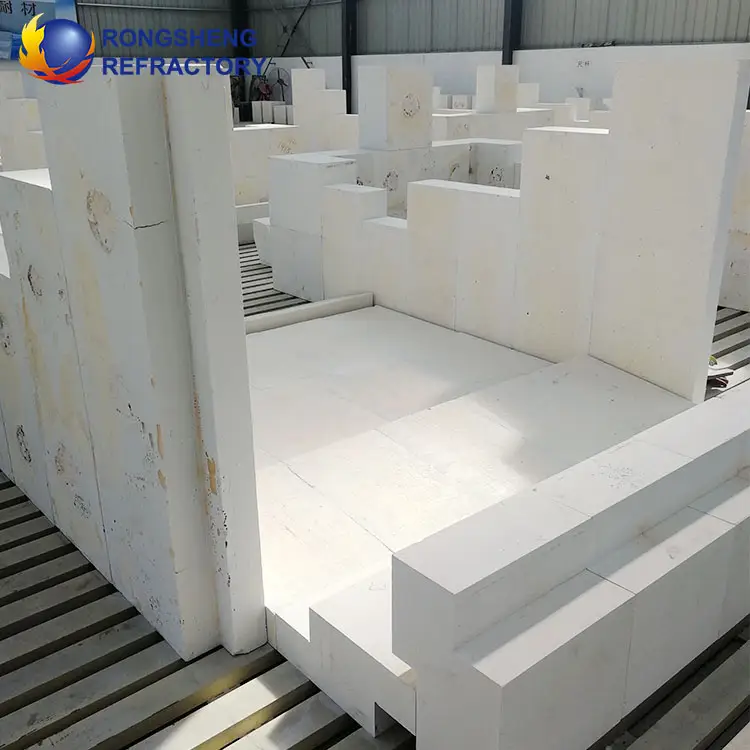

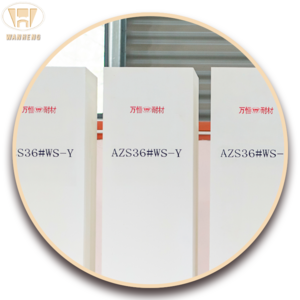

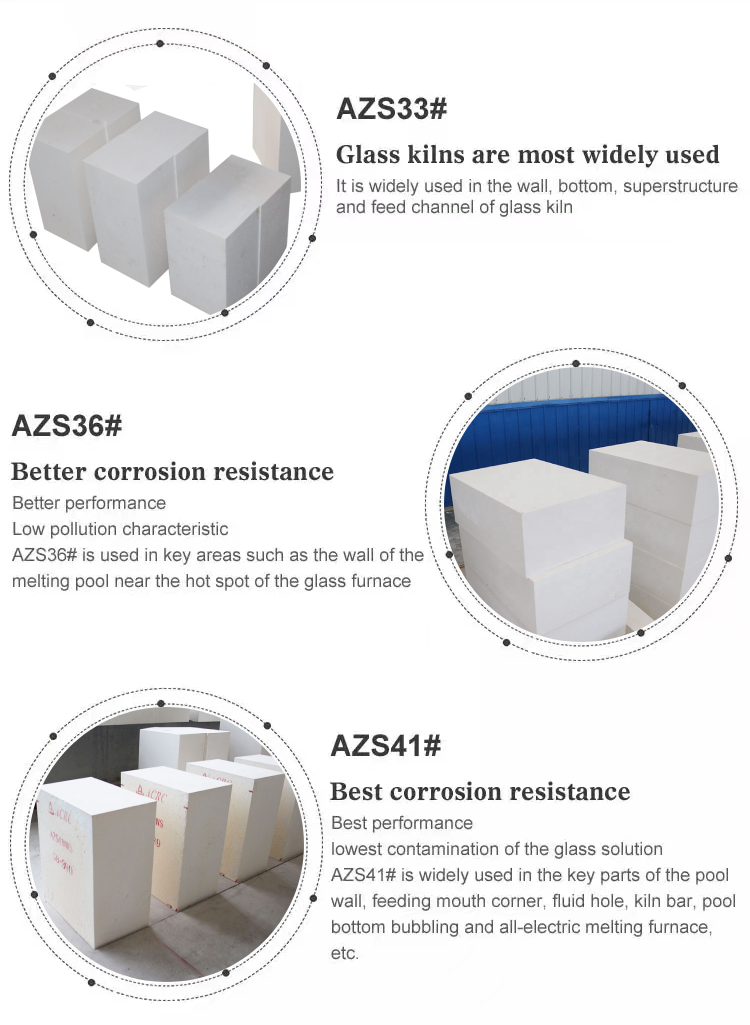

AZS bricks, also known as fused zirconia corundum bricks, are made by carefully selected zircon sand and industrial aluminum oxide powder in a 1:1 ratio, with a small amount of flux added, mixed evenly, melted at 1800~1900 ℃, and then cast into shape. Generally, zirconium corundum bricks can be divided into several grades according to the content of ZrO2, such as three grades of 33%, 36% and 41%. They have high melting point, good chemical stability, and strong corrosion resistance to acid and alkaline media, especially molten glass.

Zirconia Corundum Brick Feature

1. High refractoriness and high refractoriness under load.

2. Good wear-resistance,slag-resistance and alkali corrosion resistance.

3. Good thermal stability.

4. High compression strength.

5. Long service life.

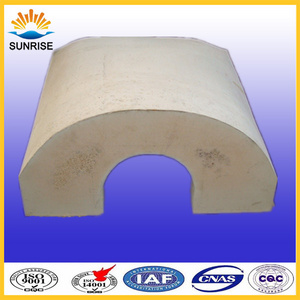

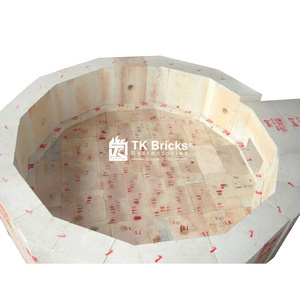

Zirconia Corundum Brick Application

AZS bricks are used in industrial furnaces, such as glass furnaces, Sodium silicate furnace, ceramic frit furnace,chemical industrial, metallurgical furnaces,etc.

|

Chemical composition |

AZS-33 |

AZS-36 |

AZS-41 |

|

ZrO2 |

≥33 |

≥35 |

≥40 |

|

SiO2 |

≤16.0 |

≤14 |

≤13.0 |

|

Al2O3 |

a little |

a little |

a little |

|

Na2O |

≤1.5 |

≤1.6 |

≤1.3 |

|

Fe2O3+TiO2 |

≤0.3 |

≤0.3 |

≤0.3 |

Physical Properties

|

Bulk density(g/cm3): |

3.5-3.6 |

3.75 |

3.90 |

|

|

Cold crushing Mpa |

350 |

350 |

350 |

|

|

Thermal expansion coefficient (1000°C) |

0.80 |

0.80 |

0.80 |

|

|

Exudation temp. of glass phase |

1400 |

1400 |

1400 |

|

|

Corrocion resistance of glass melt(mm/24h) |

1.6 |

1.5 |

1.3 |

|

|

Density |

PT QX |

3.40 |

3.45 |

3.55 |

|

WS ZWS |

3.60 |

3.70 |

3.8 |

|

Phase composition ( % )

|

Baddeleyite |

32 |

35 |

40 |

|

Glass phase |

21 |

18 |

17 |

|

A- corundum |

47 |

47 |

43 |