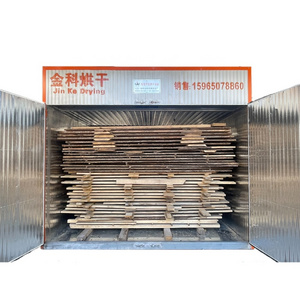

The design of headwind circulation mode, 1.0-meter away from the ceiling of the kiln, is an aluminum-type slab partition, which divides the space of the kiln into upper and lower parts. The upper part is the fan room, where the fan is installed, and the lower part is the drying kiln, which is used for wood installation.

The radiator is fixed on the two-storey shed. After the wind sent by the fan is heated through the radiator, it passes into and out of the wood pile from one side of the air duct and flows out from the other side, forming the air circulation loop in the kiln and making the wood heated and dried in the kiln.