- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

Q195 Q235 SAE1006 SAE1008

-

Place of Origin:

-

Tianjin, China

-

Model Number:

-

003

-

Brand Name:

-

BO YI DA

-

Delivery Time:

-

7-35 day's

-

Product name:

-

Galvanized wire

-

Material:

-

High Carton Steel 82B/77B

-

Diameter:

-

2.5mm

-

MOQ:

-

10 Tons

-

Key word:

-

Wire Galvanizad

-

Surface treatment:

-

Hot-dip Galv

-

Wire Gauge:

-

1-12MM

-

Surface:

-

Galvanised Zinc

-

Length:

-

Customized Length

Quick Details

-

Steel Grade:

-

Q195 Q235 1006 1008

-

Type:

-

galvanized

-

Tolerance:

-

±1%

-

Grade:

-

Q195 Q235 SAE1006 SAE1008

-

Place of Origin:

-

Tianjin, China

-

Model Number:

-

003

-

Brand Name:

-

BO YI DA

-

Delivery Time:

-

7-35 day's

-

Product name:

-

Galvanized wire

-

Material:

-

High Carton Steel 82B/77B

-

Diameter:

-

2.5mm

-

MOQ:

-

10 Tons

-

Key word:

-

Wire Galvanizad

-

Surface treatment:

-

Hot-dip Galv

-

Wire Gauge:

-

1-12MM

-

Surface:

-

Galvanised Zinc

-

Length:

-

Customized Length

Specifications:

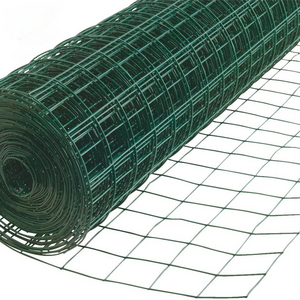

Product Introduction:

Galvanized wire is a metal cord that is coated with zinc to protect it from corrosion. This process is called galvanization, and it creates a barrier that prevents water and oxygen from reaching the steel. The zinc coating makes galvanized wire resistant to rust and damage. It's also solid and robust, protecting the wire from scratching, cutting, and chipping. High Tensile GALVANIZED HT WIRE 1.6mm 1200m is flexible and easy to use. It is coated with Zinc to make it rust-resistant. Ideal as a "weaving" wire, it is shiny, versatile, and available in a variety of gauges. Our galvanized steel strand products have excellent mechanical properties. .

Galvanized wire As tying wire in agriculture for vines and orchards, as weaving wire in the fencing and netting industry, as material for packaging of products and other daily uses. Welding fabrications before and after galvanizing is common. Requirements to allow for this are relatively simple to implement. Both welding before and after galvanizing are compatible with the objective of providing superior corrosion protection. AWS D-19.0 calls for welds of galvanized steel on areas free of zinc. Thus, for galvanized structural fabrications, the zinc coating should be removed at least 1-4 (2.5-10 cm) from either side of the intended weld zone and on both sides of the piece. The most common and preferred removal method is grinding back the zinc coating, but burning the zinc away or pushing it back from the weld area are also effective.

Advantage:

Galvanized wires are resistant to long-term damage such as scratching and breaks that would typically cause many problems. Because galvanized metal is considerably harder to damage, you won't need to spend money or time repairing wires that suffered from harm; they won't lose their effectiveness.