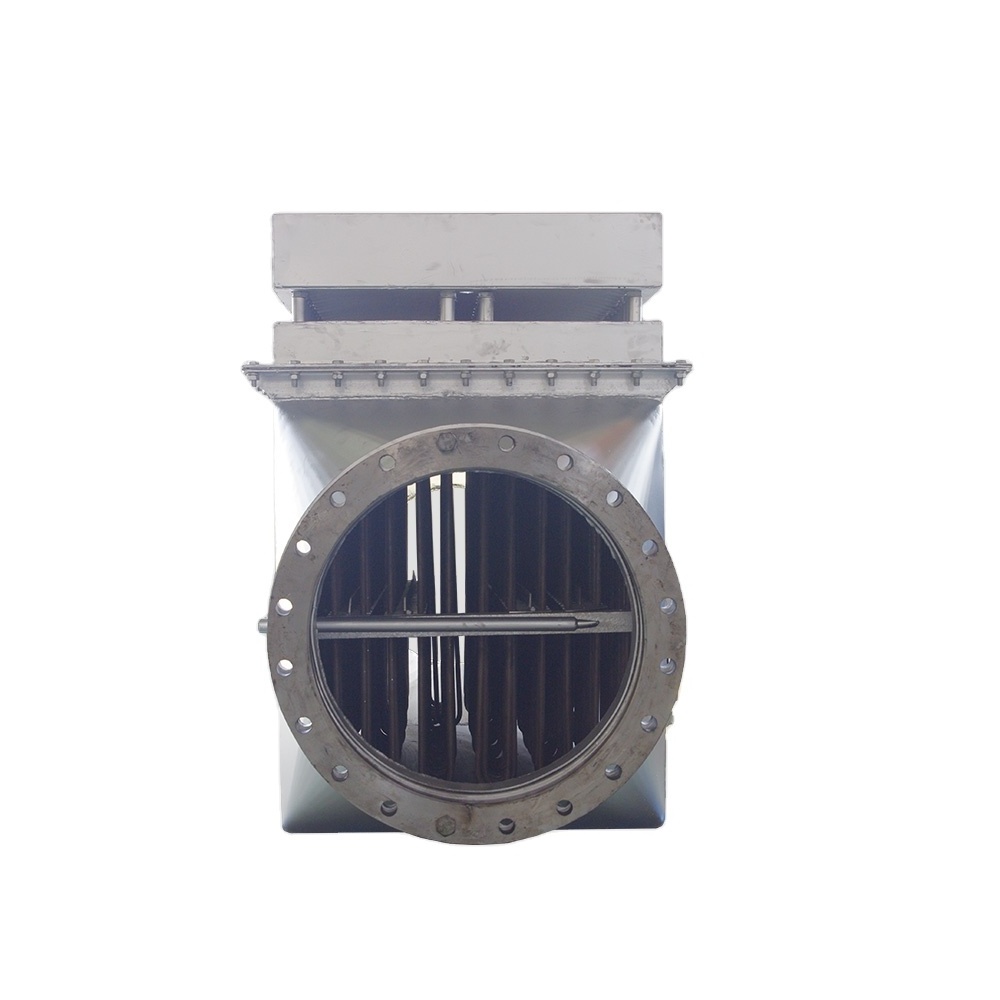

An air heater is an electric heating device that primarily heats a gas stream. The heating element of the air heater is a stainless steel electric heating tube, and the heater inner cavity is provided with a plurality of baffles to guide the gas flow

direction, prolonging the residence time of the gas in the inner cavity, so that make the gas even heating to improve heat exchange efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

RYAN

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

Customized

-

Working Temperature Range:

-

1 - 600 ℃

-

Core Components:

-

Accurate Temperature Control, heater furnace

-

Color:

-

Customized

-

Application:

-

Melt-Blown Nonwoven Industry

-

Material:

-

304 Stainless Steel

-

Certification:

-

CE

Quick Details

-

Type:

-

GYK

-

Power Source:

-

Electric

-

Voltage:

-

220V-380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

RYAN

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

Customized

-

Working Temperature Range:

-

1 - 600 ℃

-

Core Components:

-

Accurate Temperature Control, heater furnace

-

Color:

-

Customized

-

Application:

-

Melt-Blown Nonwoven Industry

-

Material:

-

304 Stainless Steel

-

Certification:

-

CE

Products Description

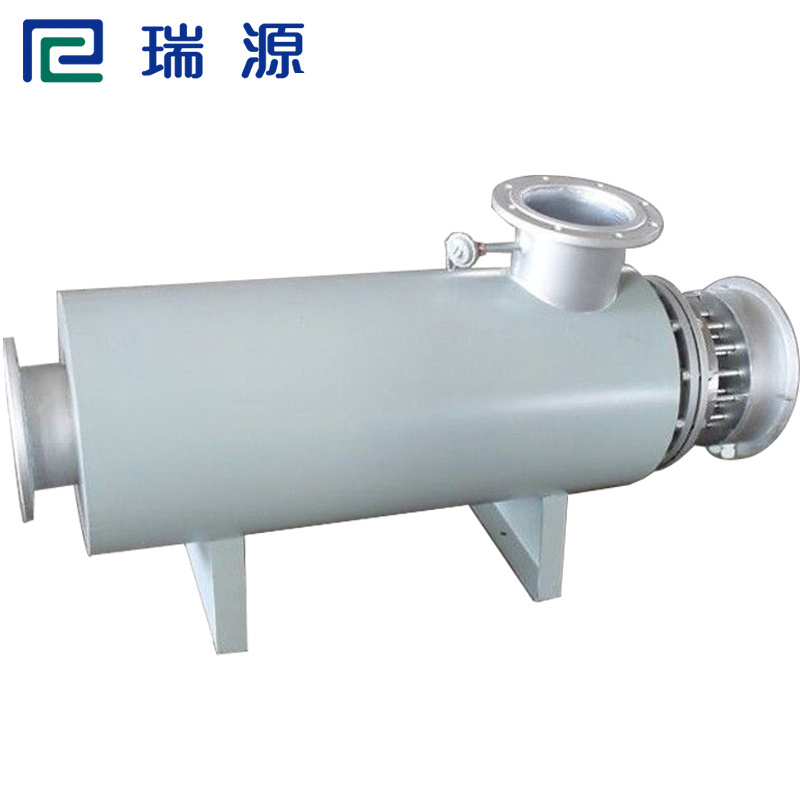

Air Heater

Pipe air heater has been widely used in many research and production laboratories such as aerospace, weapons industry, chemical industry, melt-blown non woven industry and higher education institutions. Particularly suitable for automatic temperature control and large flow high temperature combined system and accessory test.

Details Images

Product Features

|

Heat efficient more than 95%.

|

|

Fast heating and cooling.

|

|

Accurate regulation and stability.

|

|

Durable equipment, easy maintenance.

|

|

Short pipe distance against the loss of heat.

|

A. Mechanical part

1. Heating cylinder: 304 stainless steel for inner cylinder, carbon steel for shell.

2. Flange heater: 304 stainless steel and air inlet&outlet flange specification is DN150,1.6Mpa.

3. Sealing gasket: spiral wound gasket among flange.

4. Terminal box: A terminal box is set at top of the heating tank and the terminal box is equipped with a protective shell. The terminals of all heating pipes are arranged in the terminal box and the heating pipe terminal is drawn through the bronze plate.

5. Thermal insulation layer: the outside of the heating cylinder is installed with thermal insulation layer, alumina silicate

fiber, thickness≥100mm.

6. Welding: the type and size of the welded joint in accordance with HG20583-1998.

B.Electrical elements

1. Heating cylinder: 304 stainless steel for inner cylinder, carbon steel for shell.

2. Flange heater: 304 stainless steel and air inlet&outlet flange specification is DN150,1.6Mpa.

3. Sealing gasket: spiral wound gasket among flange.

4. Terminal box: A terminal box is set at top of the heating tank and the terminal box is equipped with a protective shell. The terminals of all heating pipes are arranged in the terminal box and the heating pipe terminal is drawn through the bronze plate.

5. Thermal insulation layer: the outside of the heating cylinder is installed with thermal insulation layer, alumina silicate

fiber, thickness≥100mm.

6. Welding: the type and size of the welded joint in accordance with HG20583-1998.

B.Electrical elements

1. Temperature controller: Omron

2. Air switch: Schneider

3. Contactor: Schneider

4. Indicator light: Schneider

5. Press-button: Schneider

6. Solid-state relay: Ximaden

7. Temperature detection: from Anhui Tiankang

8. Terminal strip: from Aoyu

2. Air switch: Schneider

3. Contactor: Schneider

4. Indicator light: Schneider

5. Press-button: Schneider

6. Solid-state relay: Ximaden

7. Temperature detection: from Anhui Tiankang

8. Terminal strip: from Aoyu

Why Choose Us

Hot Searches