- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1080

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Product name:

-

polishing machine

-

Color:

-

Can be paint on request.

-

Supplier by Area:

-

Asia

-

Supplier Types:

-

Supplier

-

Mgnt Certification:

-

ISO9001

-

Suppliers by Country/Region:

-

China

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HUMO

-

Power (kW):

-

5.5

-

Weight (KG):

-

1080

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Product name:

-

polishing machine

-

Color:

-

Can be paint on request.

-

Supplier by Area:

-

Asia

-

Supplier Types:

-

Supplier

-

Mgnt Certification:

-

ISO9001

-

Suppliers by Country/Region:

-

China

|

Model

|

LZG(B)100

|

LZG(B)150

|

LZG(B)200

|

LZG(B)300

|

LZG(B)400

|

LZG(B)600

|

|

Total volume(L)

|

100

|

150

|

200

|

270

|

480

|

660

|

|

Max overall dimension(mm)

|

1080

|

1170

|

1200

|

1370

|

1430

|

1860

|

|

Motor installation tube(mm)

|

φ460

|

φ460

|

φ530

|

φ630

|

φ630

|

φ900

|

|

Process bowl width(mm)

|

φ220

|

φ260

|

φ252

|

φ275

|

φ330

|

φ390

|

|

Unload width(mm)

|

250

|

210

|

250

|

320

|

380

|

470

|

|

Machine height(mm)

|

980

|

860

|

940

|

960

|

1270

|

1140

|

|

Unload height(kw)

|

800

|

710

|

770

|

760

|

1090

|

925

|

|

Media unload height(kg)

|

470

|

440

|

360

|

290

|

570

|

400

|

|

Motor(kw)

|

1.5/2.2

|

2.2

|

3.0

|

3.7/5.0

|

5.0

|

5.5/7.5

|

|

Weight(kg)

|

280

|

320

|

460

|

650

|

780

|

1180

|

Structure:

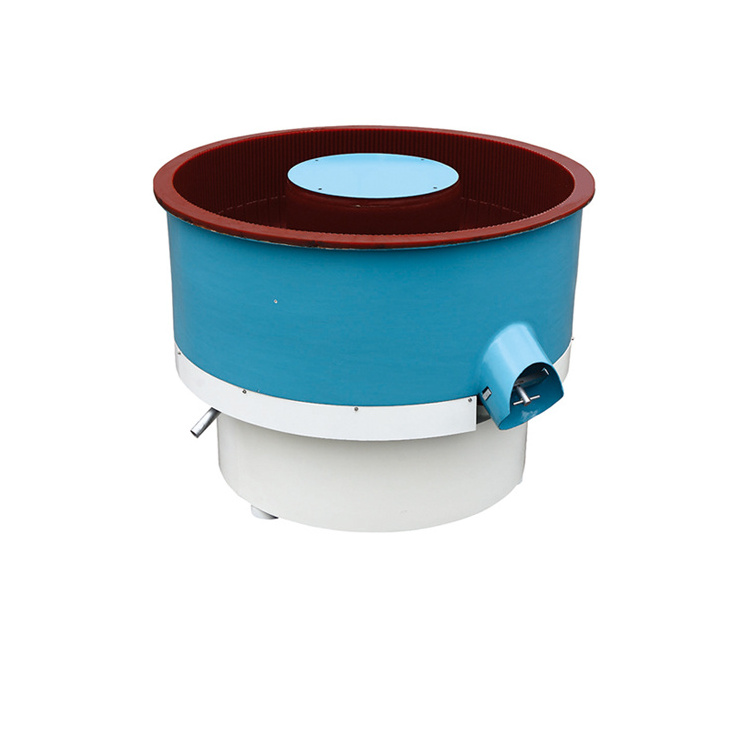

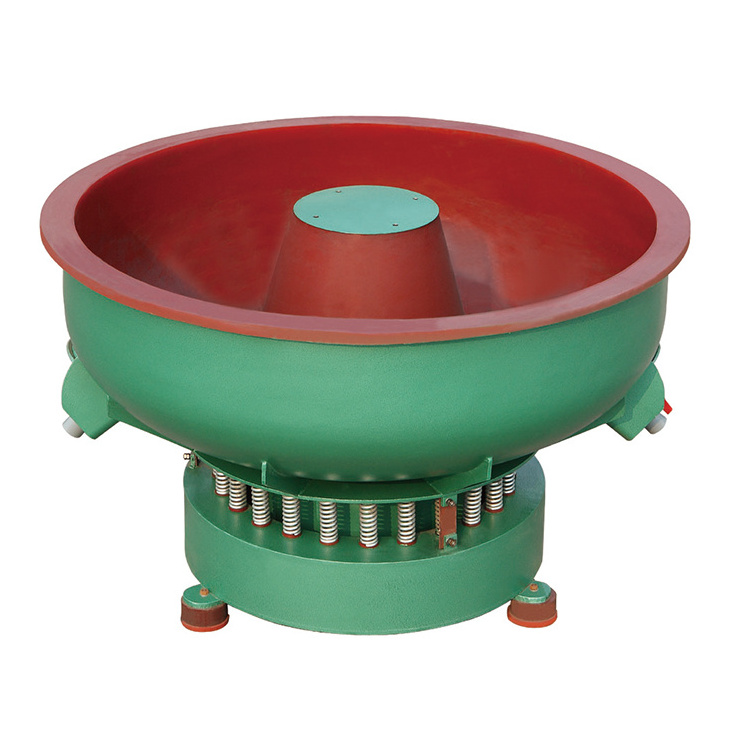

1)Humo Vibratory finishing machine is composed of inertial vibrator, vessel, electrical cabinet and basement.

2)Inertial vibrator: This is the vibrating source of the machine; it is composed Of vibratory motor, springs and eccentric blocks.

3)Vessel: The vessel is welded of annular steel plate. It is lined with high quality wearable Polyurethane, to weaken the noise and the bump of workpieces on vessel. (For VBA series, there is a separator on the vessel to separate the workpieces from the stones. )

4)Electrical cabinet: Operate the machine by buttons on the control panel.

5)Basement: It is weld of steel, and it has springs to hold the vessel.

Specifications:

Vibratory Metal Parts Glazing Machine

1. CE, ISO9001 certificated

2. High quality with best price

3. Metal parts finishing

1. Function:

Humo Vibratory finishing machines are suitable for deburring, descaling, edge radiusing, chamfering, polishing, surface improvement, pre plating finishing all types of components including fully machined parts in metals & plastics

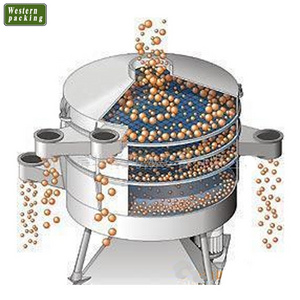

2. Working Principle

Humo Vibratory Finishing Machine for Metal Working has a ring chamber to hold abrasives (stones) and workpieces. When the machine is working, it makes three-D high frequency vibration. The grinding stones and the workpieces are rolling spirally forward and they are grinding each other during the rolling. This makes the workpieces de-burred, chamfered, polished and clean. To replace the traditional cloth-wheel polishing, the Vibratory Finishing Machine for Metal Working can save a lot of spending on manpower, and lower the cost of production. It can also be matched up with mass production, improve and stabilize the quality of the products.

3. Packing details

.

Humo Vibratory Finishing Machine is firmly packed in a plywood case in a whole. And the machine will be wrapped with thin films to protect the outside paint from scraping.

FAQ

Our laboratory services are available to you at no cost. Mass Finishing and determination of Process Capability allows you to use the right media to ensure consistent production capability and built-in reproducibility of your manufacturing processes. We will work with you to determine the best media and the best processes for your parts. This step can result in:

Reduced Cycle Times

Improved RMS Finishes

Reduced Finishing Costs

Access to Latest Technology

R & D for Special Process Media

Mass Finishing describes a mechanical process where large amounts of parts are economically processed to achieve one or several surface improvement functions. These surface improvement functions include:

Cleaning

Deburring

Surface refinement

Inhibiting

Drying

These functions are not independent of each other. It is common to have several or all of these functions take place in a single mass finishing process.

Process Capability is the measured, built-in reproducibility of the product turned out by the process. Such a determination is made using statistical data, not wishful thinking. Statistically determined limits are compared to specification limits to decide if a process can consistently produce acceptable product. Process capability is best established through closely monitored testing and recording of data over a set period of actually production.

Hot Searches