- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

Ace-Filling

-

Dimension(L*W*H):

-

3700*2100*2400

-

Weight:

-

3700 KG

-

Keywords:

-

filling plant

-

Function:

-

Bottle Washing Filling Capping

-

Usage:

-

Beverage Filling Packaging

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

3000-10000BPH

-

Material:

-

Stainless Steel 304/316

-

Suitable for:

-

Carbonated Drink Filling Line

-

Processing Types:

-

Gas Drinks

-

Filling range:

-

200-2000ml

-

Product name:

-

Automatic 3 In 1 Carbonated Drink Production Line

Quick Details

-

Machinery Capacity:

-

Other, 10000BPH, 3000BPH, 5000BPH, 7000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Carbonated drink

-

Filling Accuracy:

-

99%

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

Ace-Filling

-

Dimension(L*W*H):

-

3700*2100*2400

-

Weight:

-

3700 KG

-

Keywords:

-

filling plant

-

Function:

-

Bottle Washing Filling Capping

-

Usage:

-

Beverage Filling Packaging

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

3000-10000BPH

-

Material:

-

Stainless Steel 304/316

-

Suitable for:

-

Carbonated Drink Filling Line

-

Processing Types:

-

Gas Drinks

-

Filling range:

-

200-2000ml

-

Product name:

-

Automatic 3 In 1 Carbonated Drink Production Line

Ace-filling Machine.

Ace-filling (Suzhou) Packaging Machinery Co., Ltd. is a professional manufacturer of liquid beverage packaging solutions. We supply water treatment, water filling production line, carbonated drink making filling production line, juice making filling production line, 5 gallon filling production line, labeling machine and shrink packing machine.

Product Description

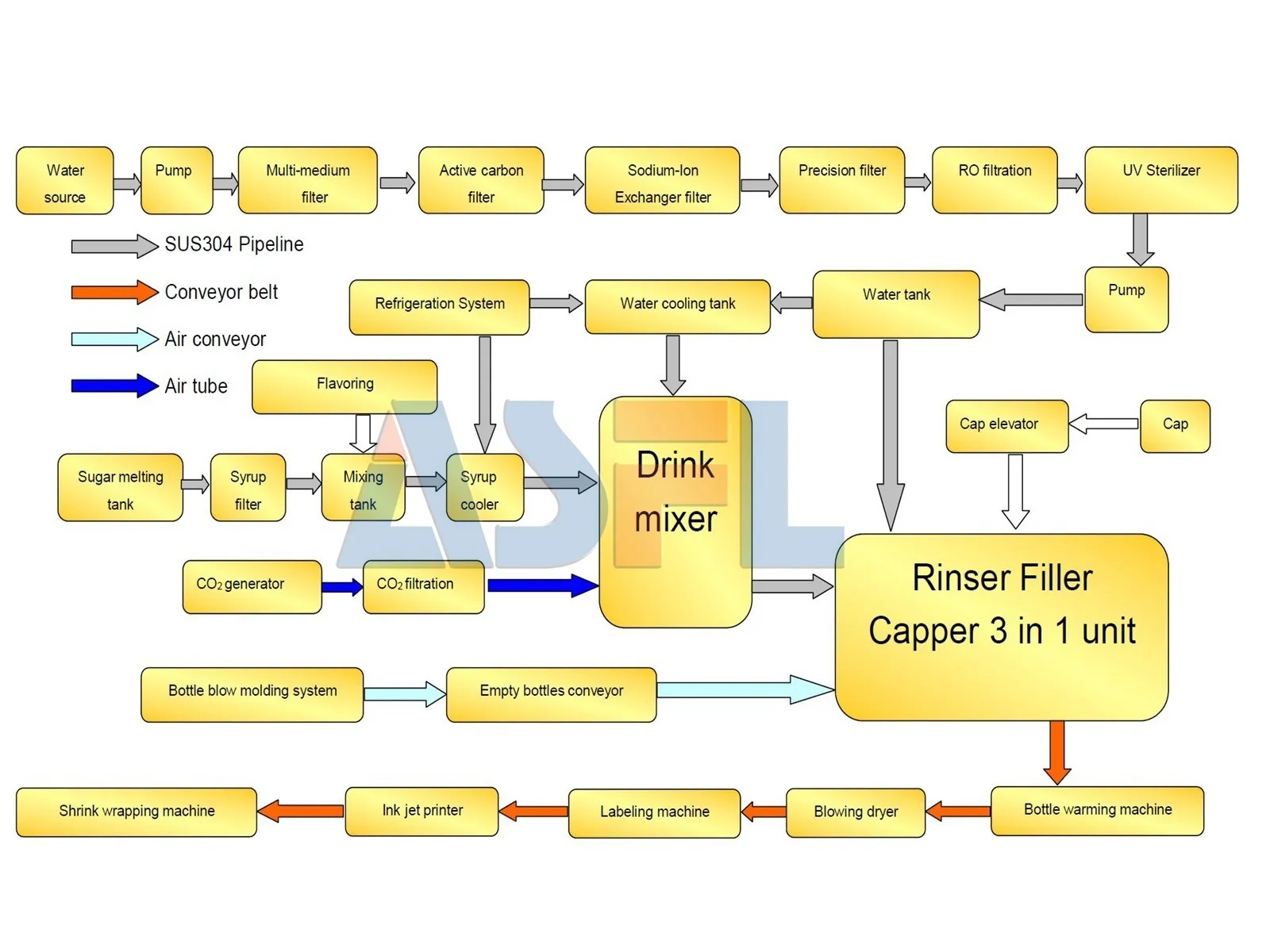

Factory Layout-CSD Filling Line

ACE-Filling Carbonated Soft Drink Filling Line

Fully automatic carbonated soft drink filling machine adopts isobaric filling technology ,the filling machine generally

maintains a certain filling pressure in the storage tank.When the bottle enters the filling machine ,the bottles is filled with gas firstly.T he gas can be compressed air or carbon dioxide gas.Carbon dioxide gas is the best .When the pressure in the bottle is the same as that in the storage tank,it is filled with the weight of the liquid through the open filling valve .In the filling process,the gas in the container should be exported smoothly and returned to the storage tank or the gas chamber.

maintains a certain filling pressure in the storage tank.When the bottle enters the filling machine ,the bottles is filled with gas firstly.T he gas can be compressed air or carbon dioxide gas.Carbon dioxide gas is the best .When the pressure in the bottle is the same as that in the storage tank,it is filled with the weight of the liquid through the open filling valve .In the filling process,the gas in the container should be exported smoothly and returned to the storage tank or the gas chamber.

Final Products

|

Equipment Type

|

Automatic

|

|

Bottle Type |

PET round or square bottle

Volume 200 - 2000ml Bottle diameter 50-115mm Bottle height 160-320mm |

|

Output

|

up to 24,000 bph

|

|

Your product

|

carbonated soft drink / cola / soda water and so on.

|

Product Details

Rinsing system

The machine is rotary rinsing machine, mainly used for rinsing beverage bottles etc. The new bottle enters into the

equipment through bottle distribution screw and star wheel, and its neck is clipped to mouth down by the clamp and turner device,dry after rinsing, and turn to mouth up automatically, then enters into the filling machine through bottle-outlet star wheel conveyor.

equipment through bottle distribution screw and star wheel, and its neck is clipped to mouth down by the clamp and turner device,dry after rinsing, and turn to mouth up automatically, then enters into the filling machine through bottle-outlet star wheel conveyor.

Filling system

PET bottled liquid bottle filler design of filling structure is reasonable and hygiene dead angle, the run of equipment is stable,it can control the material from the bottleneck, the control accuracy is within ±2mm (subject to bottle design).The filling valve material is SUS304.The filling system has liquid level automatic control.Filling valve elevator, after filling valve contact the bottle neck, it starts to fill.Bottle is conveying by the wheel in the filling part.

Capping system

The capping is magnetic capping, with overload protection function, stable and reliable capping torque. Import motor gear box, reduce the secondary pollution of the bottle cap, 304 stainless steel cap chute tank, cap silo and cap chute tank with electronic capless inspection system, automatic control cap conveyor machine and running speed for the machine.

Related Products

1 / High-shear emulsifying tank + Plate heat exchanger

2 / Mixing tank

3 / UHT sterilizer + homogenizer machine + Buffer tank

4 / Hot water system + Hot water tank

5 / CIP cleaning system

2 / Mixing tank

3 / UHT sterilizer + homogenizer machine + Buffer tank

4 / Hot water system + Hot water tank

5 / CIP cleaning system

3 - Blow Molding Machine

1 / Blower : Industry-leading blower performance with patented control and self-regulation systems for repeatable and consistently high bottle quality

2 / Production flexibility: Up to 200 different equipment size configurations from one platform

3 / Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

4 / Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

2 / Production flexibility: Up to 200 different equipment size configurations from one platform

3 / Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

4 / Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

4 - DCGF Carbonated Drink Filling Machine

1 / Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

2 / Optimum uptime: 30 % reduction in changeover and maintenance downtime

3 / Hygiene improvement through volume control and contactless filling

4 / Automatic dummy bottles: Safer, easier cleaning procedures

5 / Automatic bottle changeover improves uptime

2 / Optimum uptime: 30 % reduction in changeover and maintenance downtime

3 / Hygiene improvement through volume control and contactless filling

4 / Automatic dummy bottles: Safer, easier cleaning procedures

5 / Automatic bottle changeover improves uptime

5 - Bottle

Warming

System

1/ Mainly for

warming

and sterilization

2/ The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and observation

3/ Nozzles are manufactured using U.S. technology and spray water evenly

4/ Conveyor belt adopts Rexnor technology, flat surface with small wear

5/ Smooth and reliable operation with low energy consumption

2/ The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and observation

3/ Nozzles are manufactured using U.S. technology and spray water evenly

4/ Conveyor belt adopts Rexnor technology, flat surface with small wear

5/ Smooth and reliable operation with low energy consumption

According to customer requirements and market needs, we can provide better solutions for the packaging of the final product. The

packaging machine has film shrinking machine and carton packaging for you to choose.

packaging machine has film shrinking machine and carton packaging for you to choose.

Product Paramenters

|

Model

|

DCGF16-12-6

|

DCGF18-18-6

|

DCGF24-24-8

|

||

|

Capacity(for 500ml)

|

3500-4000BPH

|

4500-6000BPH

|

8000-1200BPH

|

||

|

Suitable bottle shapes

|

Circular or square

|

|

|

||

|

Suitable bottle(mm)

|

(Diameter)φ50-.φ108mm (Height):150-310mm

|

|

|

||

|

Rinsing pressure

|

>0.06Mpa <0.2Mpa

|

|

|

||

|

Filling pressure

|

<0.4 Mpa

|

|

|

||

|

Total power (KW)

|

4.24

|

5.03

|

6.57

|

||

|

Overall dimensions

|

2.1*1.6m

|

2.45*1.8m

|

2.75*2.18m

|

||

|

Height

|

2.2m

|

2.2m

|

2.2m

|

||

|

Weight(kg)

|

2500kg

|

3500kg

|

4500kg

|

||

|

Model

|

DCGF32-32-10

|

DCGF40-40-12

|

DCGF50-50-12

|

DCGF60-60-15

|

|||

|

Capacity (for 500ml)

|

12000-14000

|

15000-18000

|

21000-24000

|

26000-30000

|

|||

|

Suitable bottle shapes

|

Circular or square

|

|

|

|

|||

|

Suitable bottle(mm)

|

(Diameter)φ50-.φ108mm (Height):150-310mm

|

|

|

|

|||

|

Rinsing pressure

|

>0.06Mpa <0.2Mpa

|

|

|

|

|||

|

Filling pressure

|

<0.4 Mpa

|

|

|

|

|||

|

Total power (KW)

|

8.63

|

9.63

|

12.5

|

15

|

|||

|

Ovaerall dimensions

|

3.5*2.2m

|

4*3m

|

5.5*4.5m

|

7*6.5m

|

|||

|

Height

|

2.25m

|

2.25m

|

2.25m

|

2.25m

|

|||

|

Weight (KG)

|

6000

|

8000

|

10500

|

13000

|

|||

Recommend Products

Why Choose Us

Ace-Filling Machine

Ace-filling (Suzhou) Packaging Machinery Co., Ltd. is a professional manufacturer of liquid beverage packaging solutions. We supply bottle blowing machine, water treatment, water filling production line, carbonated drink making filling production line, juice making filling production line, 5 gallon filling production line, labeling machine and shrink packing machine. With our machines, bottles can be plastic bottle, glass bottle barrel and cans. In other words, machines can be customized according to client's requirements. We have exported to South East Asia, Middle East, Africa and South America and South East,more than 40 countries. We are always focusing on the researches and developments, since they are our key of enterprise innovation. They make us better doing in production, technical services and marketing sales.

Production Process

In the production process, we strictly control the quality of the product. It consists of ten processes, including

welding,drilling,bending,machining,assembling,bebugging&test and acceptance. After repeated testing, the practice finally put into use.

welding,drilling,bending,machining,assembling,bebugging&test and acceptance. After repeated testing, the practice finally put into use.

Our Customers

We have exported to South East Asia, Middle East, Africa and South America and South East,more than 40 countries. We are always focusing on the researches and developments, since they are our key of enterprise innovation.

FAQ

Q:Are you a manufacturer or trading company?

* Please do not hesitate to contact us if you want more details!

A:We are a manufacturer in beverage machine field more than 10 years, located at Leyu town, Zhangjiagang, 1.5 hours from Shanghai,1 hour from Wuxi by car. We will pick you up to visit our factory.

Q:Do you have any certification?

A:SGS,ISO,CE

Q:What about the delivery time?

A:Usually 45 Working days

Q:What about the machine’s capacity?

A:2000-30000 bottles in 500ml per hour.

Q:The after-sale service

A:24 months warranty. Solve basic questions by phone, email, whatsapp, Wechat and video call.

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines. Operating manuals will be sent with machine or by email.

Q:If our bottle size changes, can we just do some adjustment on machine according to our new bottle?

A:Yes.

Q: If I want to buy a machine, what information do I need to tell you, what information do you need from me?

A:1. What kind beverage you want to produce?

2. What kind of bottle and cap you will use?

3. Bottle volume? 250ml, 330ml, 500ml, 750ml, etc.?

4. Producing speed requirement? How many bottles per hour?

5. Raw water analysis report .

6. Power supply.

Q:What kinds of product you supply?

A: Drink water/juice/carbonated drink filling line.

5 gallon/20L/ can beverage/glass bottle beverage filling line.

Water treatment system.

Bottle blowing making machine.

After packing system(label machine, PE film shrink packing machine, carton machine)

* Please do not hesitate to contact us if you want more details!

Hot Searches