- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YIDAFA

-

Voltage:

-

220/380V

-

Power:

-

1000KW

-

Dimension(L*W*H):

-

2100*970*1700M

-

Weight:

-

80000 kg

-

Marketing Type:

-

New Product 2023

-

Product name:

-

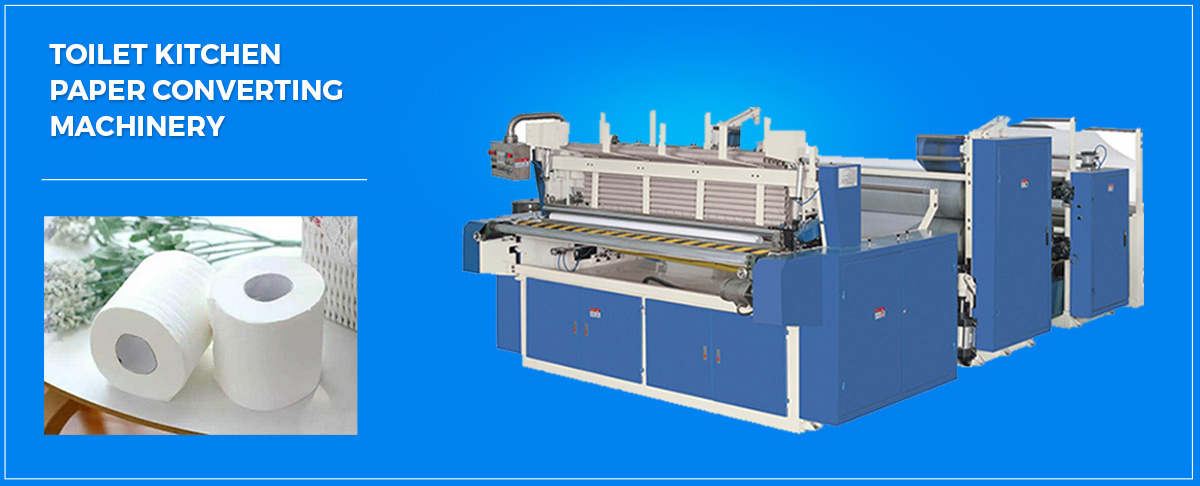

Toilet Tissue Paper Roll Rewinding Machine

-

Net paper width:

-

1575/1880/2850/3000

-

Raw material:

-

Jumbo Roll Toilet Tissue Paper

-

Application:

-

Household Tissue Paper Production

-

Output paper:

-

Toilet Paper Tissue Paper Napkin Paper

-

Keyword:

-

Automatic Toilet Paper Making Machine

-

Machine for:

-

Mini Toilet Paper Making Machine

-

Embossing unit:

-

Customized Embossing

-

Operation:

-

1-2

-

Automatic Grade:

-

High Automation/semi auto

Quick Details

-

Production Capacity:

-

10 tons per day or more

-

Processing Type:

-

Paper production machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YIDAFA

-

Voltage:

-

220/380V

-

Power:

-

1000KW

-

Dimension(L*W*H):

-

2100*970*1700M

-

Weight:

-

80000 kg

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Toilet Tissue Paper Roll Rewinding Machine

-

Net paper width:

-

1575/1880/2850/3000

-

Raw material:

-

Jumbo Roll Toilet Tissue Paper

-

Application:

-

Household Tissue Paper Production

-

Output paper:

-

Toilet Paper Tissue Paper Napkin Paper

-

Keyword:

-

Automatic Toilet Paper Making Machine

-

Machine for:

-

Mini Toilet Paper Making Machine

-

Embossing unit:

-

Customized Embossing

-

Operation:

-

1-2

-

Automatic Grade:

-

High Automation/semi auto

|

Model

|

1092/1575/1880/2400/2600/3150/3500

|

|

Width of raw paper (mm)

|

1200/1800/2100/2400/2500/3000/3500

|

|

Dia. of finished paper

|

60-150mm(tightness adjustable)

|

|

Dia. of finished paper core

|

32-50mm

|

|

Dia.of raw material

|

1100mm(other sizes are available)

|

|

Dia of core of raw material

|

76.2mm(other sizes are available)

|

|

Perforation pitch

|

4 perforating blade 90-160mm; 2 perforating blade 180-320mm

|

|

Reeling speed

|

150-200m/min

|

|

Parameter setting

|

PLC screen operation system

|

|

Unwinding unit

|

1-3 layers15-30gsm

|

|

Pneumatic system

|

3HP air compressor,Min.Pressure 5kg/cm² Pa (provided by customers)

|

|

Power

|

5.5-15kw

|

|

Overall Dimension(L*W*H)

|

6200*2600*800~6200*4000*800mm

|

|

Weight

|

3800~9000kg

|

|

Embossing Unit

|

Single ply embossing, two side embossing and steel to steel embossing(depend on selection)

|

|

Bottom Embossing Roller

|

Felt roller, wool roller and rubber roller (depend on selection)

|

|

Unwinding unit

|

1-3 ply

|

|

Unwinding unit driving

|

Gear box driving

|

|

Edge embossing unit

|

Steel to steel

|

|

Finished roll rewinding

|

Coreless rewinding system

|

|

Peforating Unit

|

Pneumatically separating unit

|

|

Calendering Unit

|

Steel to steel ,steel to rubber

|

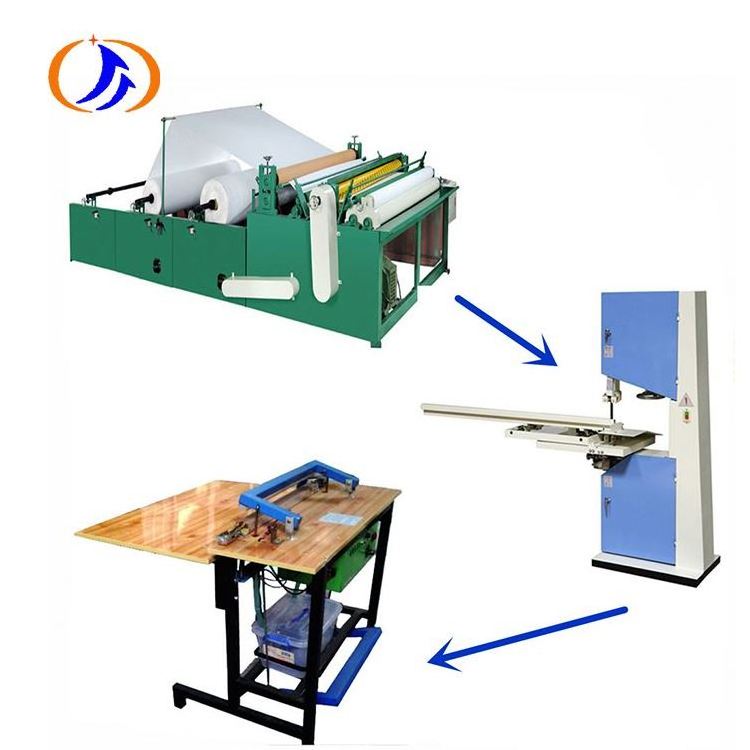

MAIN FEATURES

2.Equipped with automatic variable speed cutting machine and automatic tracking cutting, which make the paper tube length more accurate

3.The machine has reasonable design , stable performance, easy operation, stable running

4.automatic finished paper tube unload stand, which can reduce the labor intensity

1.How to install and maintain the machine?

Firstly, we will provide the installation guild with the machine for your reference.

Secondly, our company is responsible for training production workers for you, ensuring that the workers will be independent operation.

2.How can we get the matching accessories or wearing parts conveniently?

During the warranty, Our company can replace the accessories for free .Out of warranty,we can provide them at the preferable price. In fact, the wearing parts are standard parts that you could get it in your country at your convenience.

Our Services & Strength

1. The business contact on both sides will reply within 16 hours .

2. During warranty period, the company provide the relevant technical services for free,such as equipment quality problem resulting from the design and manufacturing equipment, which the company will be responsible for replacement and maintenance.

3.After the expiration of the warranty, our company provide customers with a lifelong technical

service and spare parts with preferential price and efficient manner over a long period of time.