- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Product name:

-

Carbide rods and bars

-

Material:

-

Tungsten carbide

-

Surface:

-

Blank, grounded or mirror polished

-

Size:

-

Customized

-

Advantage:

-

Excellent wear resistance,good performance

-

Samples:

-

Availabe

Quick Details

-

Alloy Specification:

-

type

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

diamond brand

-

Model Number:

-

Customized

-

Product name:

-

Carbide rods and bars

-

Material:

-

Tungsten carbide

-

Surface:

-

Blank, grounded or mirror polished

-

Size:

-

Customized

-

Advantage:

-

Excellent wear resistance,good performance

-

Samples:

-

Availabe

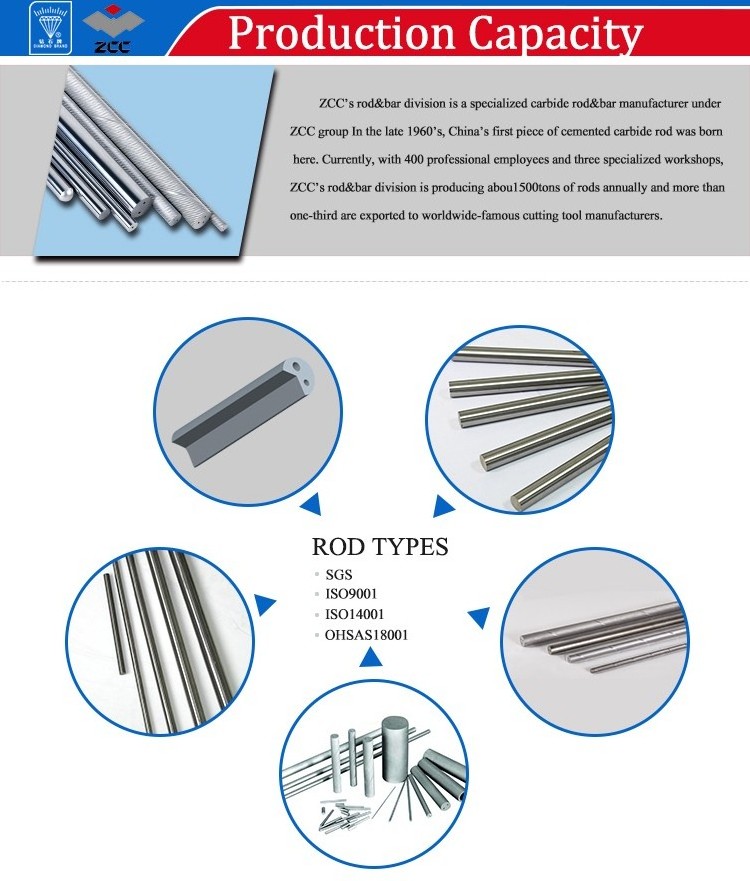

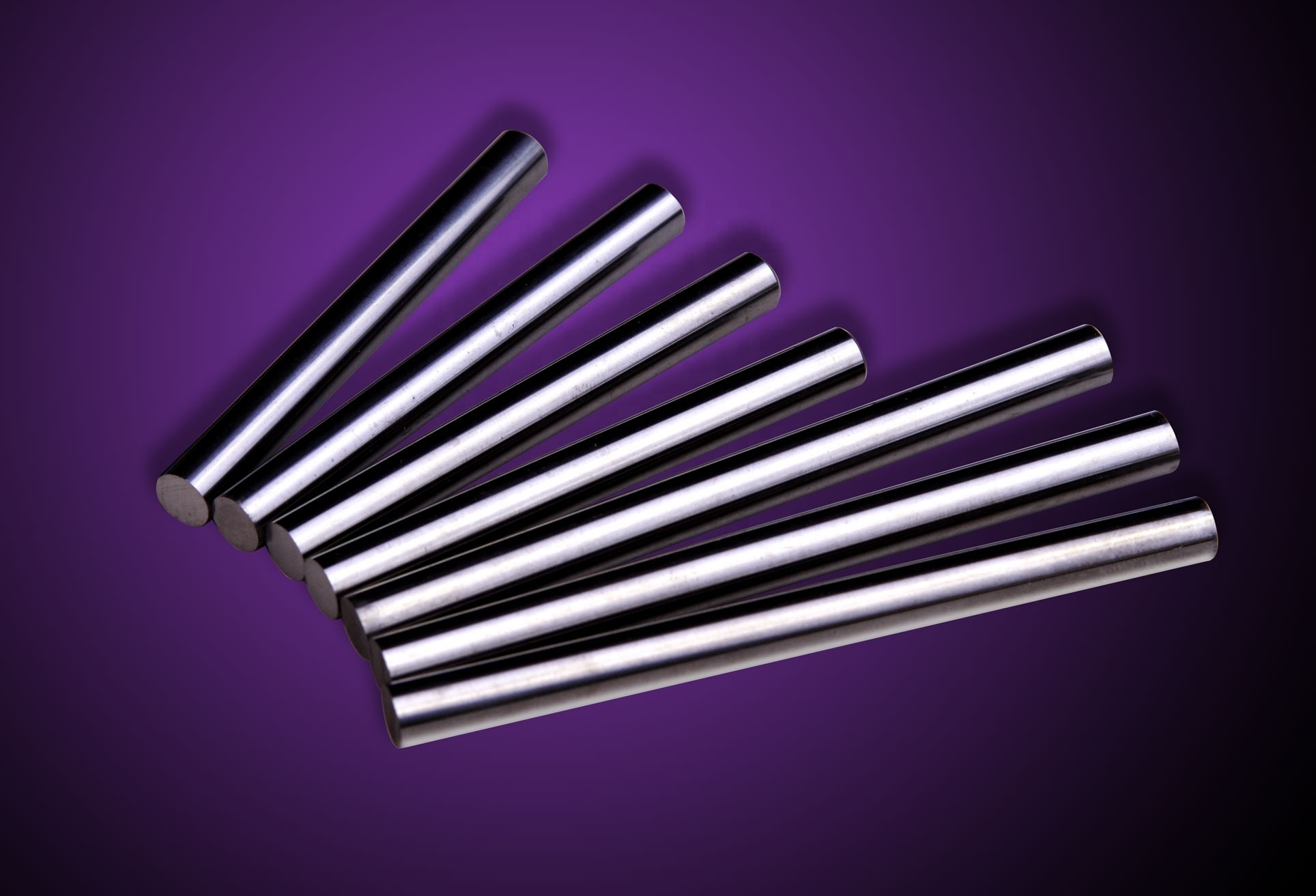

Carbide rods and bars

Carbide rods and bars

Application of Carbide rods and bars

Used for making different milling cutter, drill, punch and wear resistant parts. At present, its main application field is in machining and electronics industry.

Specification of Carbide rods and bars

| GRADE | YL06C | YL10.2 | YL10A | YF06 | XF20S | XF30S | XT30S | XU30 | XU09S | XU10W | |

| Drilling | * | * | * | * | * | ||||||

| Milling | * | * | * | * | * | * | * | * | * | ||

| Reaming | * | ||||||||||

| P | General carbon steel | ^ | # | ^ | ^ | # | |||||

| M | Stainless steel | # | ^ | ||||||||

| K | Cast Iron | ^ | # | ^ | ^ | # | |||||

| S | Ti | # | ^ | ||||||||

| HRSA | # | ||||||||||

| N | Al-Mg | ^ | # | ^ | ^ | ^ | # | ||||

| H | Hard steel | ^ | |||||||||

| Others | Plastic | # | # | ||||||||

| CFRP | ^(coated) | ||||||||||

| Wood | ^ | # | ^ | ||||||||

| Ceramic | ^(coated) |

|

Carbide Rods |

|||

|

Ground to h5/h6 |

|||

|

Length 330mm |

|||

|

Chamfered 45° |

|||

|

Type |

D (mm) |

L(mm) |

Tolerance L(mm) |

|

φ 1 .0× 330 |

1 |

330 |

0/+10.0 |

|

φ 1.5 × 330 |

1.5 |

330 |

0/+10.0 |

|

φ 2 .0× 330 |

2 |

330 |

0/+10.0 |

|

φ 2.5 × 330 |

2.5 |

330 |

0/+10.0 |

|

φ 3 .0× 330 |

3 |

330 |

0/+10.0 |

|

φ 3.5 × 330 |

3.5 |

330 |

0/+10.0 |

|

φ 4 .0× 330 |

4 |

330 |

0/+10.0 |

|

φ 4.5 × 330 |

4.5 |

330 |

0/+10.0 |

|

φ 5 .0× 330 |

5 |

330 |

0/+10.0 |

|

φ 5.5 × 330 |

5.5 |

330 |

0/+10.0 |

|

φ 6 .0× 330 |

6 |

330 |

0/+10.0 |

|

φ 6.5 × 330 |

6.5 |

330 |

0/+10.0 |

|

φ 7 .0× 330 |

7 |

330 |

0/+10.0 |

|

φ 7.5 × 330 |

7.5 |

330 |

0/+10.0 |

|

φ 8 .0× 330 |

8 |

330 |

0/+10.0 |

|

φ 8.5 × 330 |

8.5 |

330 |

0/+10.0 |

|

φ 9 .0× 330 |

9 |

330 |

0/+10.0 |

|

φ 9.5 × 330 |

9.5 |

330 |

0/+10.0 |

|

φ 10 × 330 |

10 |

330 |

0/+10.0 |

|

φ 10.5 × 330 |

10.5 |

330 |

0/+10.0 |

|

φ 11 × 330 |

11 |

330 |

0/+10.0 |

|

φ 11.5 × 330 |

11.5 |

330 |

0/+10.0 |

|

φ 12 × 330 |

12 |

330 |

0/+10.0 |

|

φ 12.5 × 330 |

12.5 |

330 |

0/+10.0 |

|

φ 13 × 330 |

13 |

330 |

0/+10.0 |

|

φ 14 × 330 |

14 |

330 |

0/+10.0 |

|

φ 15 × 330 |

15 |

330 |

0/+10.0 |

|

φ 16 × 330 |

16 |

330 |

0/+10.0 |

|

φ 17 × 330 |

17 |

330 |

0/+10.0 |

|

φ 18 × 330 |

18 |

330 |

0/+10.0 |

|

φ 19 × 330 |

19 |

330 |

0/+10.0 |

|

φ 20 × 330 |

20 |

330 |

0/+10.0 |

|

φ 21 × 330 |

21 |

330 |

0/+10.0 |

|

φ 22 × 330 |

22 |

330 |

0/+10.0 |

|

φ 23 × 330 |

23 |

330 |

0/+10.0 |

|

φ 24 × 330 |

24 |

330 |

0/+10.0 |

|

φ 25 × 330 |

25 |

330 |

0/+10.0 |

|

φ 26 × 330 |

26 |

330 |

0/+10.0 |

|

φ 28 × 330 |

28 |

330 |

0/+10.0 |

|

φ 30 × 330 |

30 |

330 |

0/+10.0 |

|

φ 32 × 330 |

32 |

330 |

0/+10.0 |

|

φ 33 × 330 |

33 |

330 |

0/+10.0 |

|

φ 34 × 330 |

34 |

330 |

0/+10.0 |

|

φ 35 × 330 |

35 |

330 |

0/+10.0 |

|

φ 36 × 330 |

36 |

330 |

0/+10.0 |

|

φ 38 × 330 |

38 |

330 |

0/+10.0 |

|

φ 40 × 330 |

40 |

330 |

0/+10.0 |