- Product Details

- {{item.text}}

Quick Details

-

Current:

-

NA

-

Rated Capacity:

-

2300W

-

Rated Duty Cycle:

-

95%

-

Dimensions:

-

L540*W310*H500mm

-

Use:

-

Repair

-

Product name:

-

BGA REWORK STATION

-

PCB size:

-

Max 170*220 mm Min 22*22 mm

-

BGA chip:

-

2*2~80*80mm

-

Positioning:

-

V-groove+PCB bracket+universal fixtures

-

Temperature accuracy:

-

±2℃

-

Heating way:

-

Top hot air;bottom infrared

-

Top heater:

-

hot air 1200w

-

Bottmer heater:

-

Infrared 1100

-

Weight:

-

16KG

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

India

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Certification:

-

CE/ISO9001

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dinghua

-

Voltage:

-

AC220V 10% 50/60Hz

-

Current:

-

NA

-

Rated Capacity:

-

2300W

-

Rated Duty Cycle:

-

95%

-

Dimensions:

-

L540*W310*H500mm

-

Use:

-

Repair

-

Product name:

-

BGA REWORK STATION

-

PCB size:

-

Max 170*220 mm Min 22*22 mm

-

BGA chip:

-

2*2~80*80mm

-

Positioning:

-

V-groove+PCB bracket+universal fixtures

-

Temperature accuracy:

-

±2℃

-

Heating way:

-

Top hot air;bottom infrared

-

Top heater:

-

hot air 1200w

-

Bottmer heater:

-

Infrared 1100

-

Weight:

-

16KG

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

India

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Certification:

-

CE/ISO9001

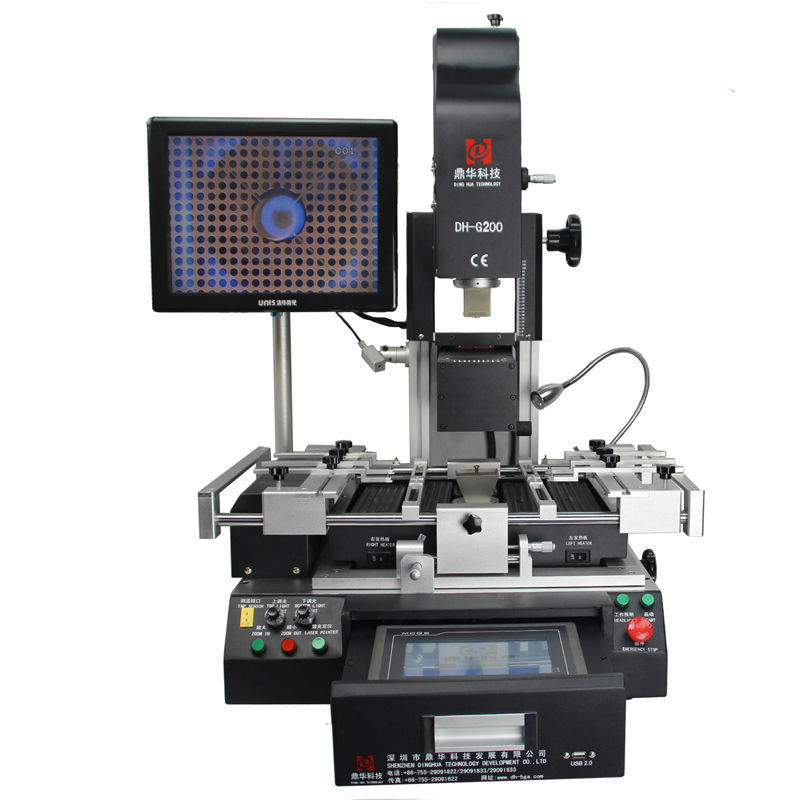

DH-200 BGA rework reballing machine soldering station

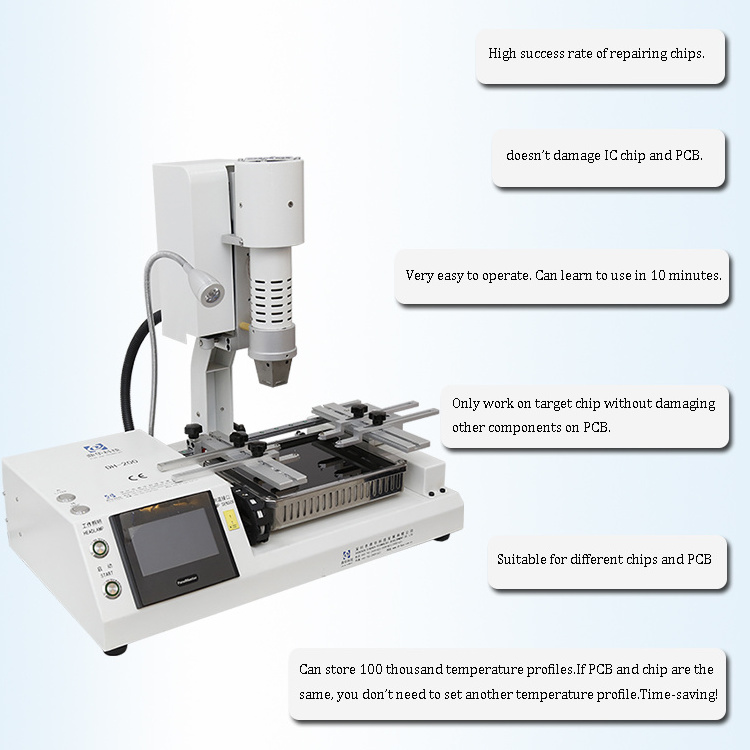

Advantages of DH-200 BGA rework station

1. High success rate of repairing chips.Precise temperature control ensure temperature change according to the materials of the solder balls.

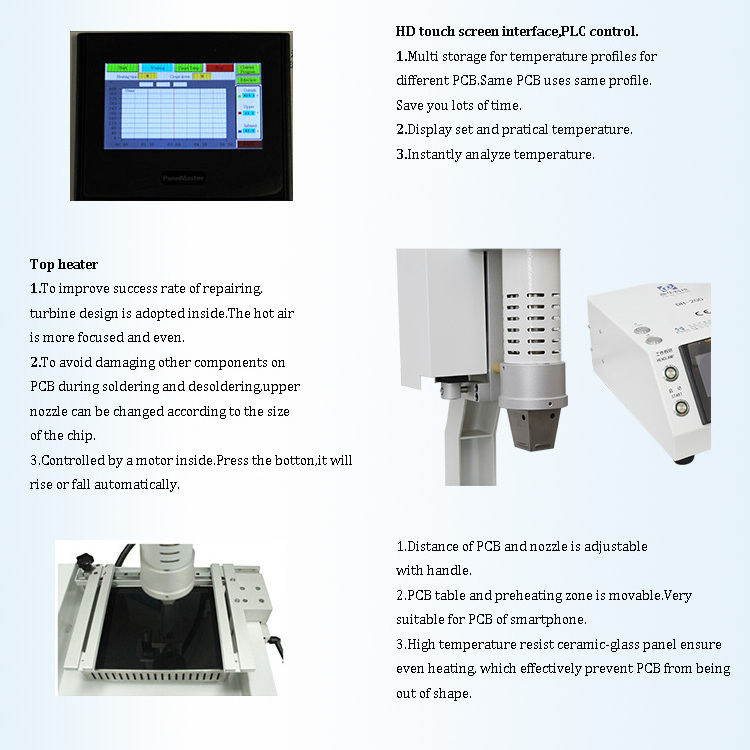

2. Precise temperature control.Target chip can be soldered or desoldered while no other components on PCB are damaged.

(1)No false welding or fake welding.

(2)The frequency of one PID value running in one cycle is about 10 milliseconds while one cycle time of one PID value of our competitors is about 40-60 milliseconds. The faster it captures the frequency, the more precise its temperature control is.

(3)Hot air nozzle is made of Titanium alloy without being rusted,out of shape or discolored.When temperature is too high for the chip,backflow tank design makes hot air reflux to ensure that the bridge will not be detonated, and the peripheral components will not be damaged at the same time.

(4)Two independent heating areas increase temperature gradually,which cannot damage IC chip.Even after PCB has been repaired for times,the appearance and functions of PCB are not affected.

5. Humanized design makes the machine easy to operate. Normally a worker can learn to use it in 10 minutes. No special professional experiences or skills is needed, which is time- and energy-saving for your company.

6. Suitable for various types of PCB of any size.

7. Superior materials guarantee long life span.Built-in,upper and bottom cooling fan cool the machine automatically as soon as heating proccess is finished,which effectively avoids deterioration and aging of machine.3-year warranty for heating system is offered.

8. Lifetime unlimited technical support and free training are offered.

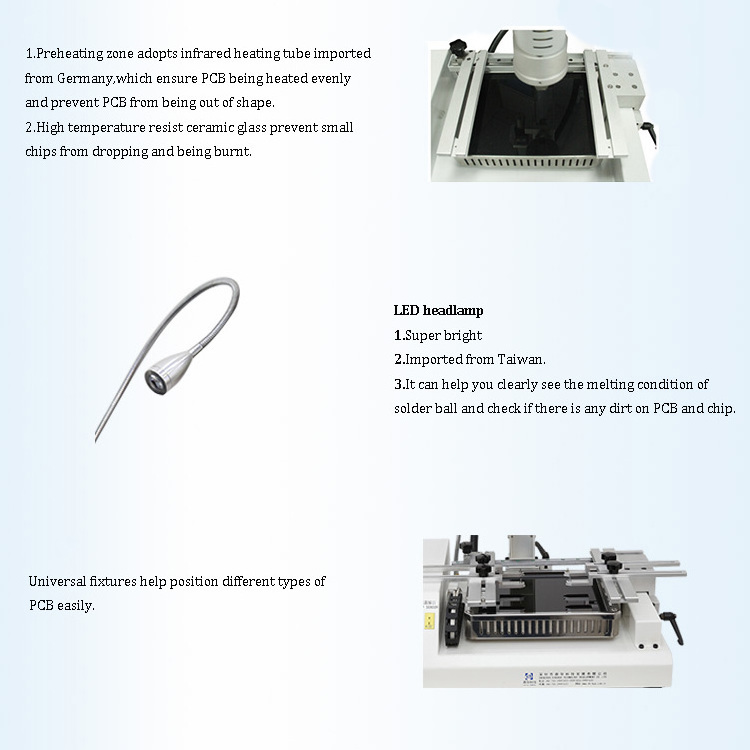

9. The super bright LED headlamp is imported from Taiwan Top manufacturer.It can help you clearly see the melting condition of solder ball and check if there is any dirt on the PCB and chip.

Specification of DH-200 BGA Rework Station:

| Power | 2300W |

| Top heater | Hot air 1200w |

| Bottom heater | Infrared 1100w |

| Power supply | AC220v±10%,50/60HZ |

| Dimenssion | L540*W310*H500mm |

| Positioning | V-groove+PCB bracket+universal fixtures |

| Temperature control | K type thermocouple,closed loop control,independent heating |

| Temperature accuracy | ±2℃ |

| PCB size | Max 170*220 mm Min 22*22 mm |

| BGA chip | 2*2~80*80mm |

| Temp sensor | 1(optional) |

| Net weight | 16KG |

Details of DH-200 BGA Rework Station:

1. Strict quality control.

2. Even after PCB and chips have been repaired on BGA rework station for several times,the appearance and functions are not affected.

3. Wide range of application:

Motherboard of computer,smartphone,laptop,digital camera ,air conditioner,TV and other electronic equipments from medical industry,communication industry,automobile industry,etc.

Wide range of application:BGA,PGA,POP,BQFP,QFN,SOT223,PLCC,TQFP,TDFN,TSOP,

PBGA,CPGA,LED chip.

4. High success rate of BGA or other chips rework.

Pre-sales serveice

*Inquiry and consulting is welcome.30min instant reply.

*Sample testing.

*Visiting our factory

*Free professional training

After-sales service

*Free professional training

*Warranty:3 years for heating system and 1 year for whole machine

*Engineer available to serv machinery overseas.

Packing List:

1.Machine:1 set

2.All packed in stable and strong wooden cases,suitable for import and export.

3.Top nozzle:3 pcs (31*31mm,38*38mm,41*41mm)

Bottom nozzle:2pcs(34*34mm,55*55mm)

4.Beam:2 pcs

5.Plum knob: 6 pcs

6.Universal fixture:6 pcs

7.Support screw:5 pcs

8.Brush pen:1 pcs

9.Vacuum cup:3 pcs

10.Vacuum needle:1 pcs

11.Tweezer:1 pcs

12.Temp sensor wire:1 pcs

13.Professional Instruction Book:1 pcs

14.Teaching CD: 1 PCS

Shipping:

1.Shipment will be made within 5 business days after receiving payment.

2.Fast delivery shipment by DHL,FedEX,TNT and other ways including by sea or by air.