CO-WIN is a company that designs, manufactures and maintains high-quality hydraulic presses.

We have been at the forefront of the hydraulic press industry for many years, servicing a wide range of industries including automotive, aerospace, manufacturing and more. Our commitment to excellence and innovation makes us a trusted partner to businesses around the world.

We understand the critical role hydraulic presses play in modern manufacturing processes. These machines are the backbone of many industries, capable of forming, shaping and transforming a wide range of materials with precision and reliability.

We use state-of-the-art technology and the latest advancements in hydraulic systems to ensure our machines operate at the highest levels of performance and efficiency.

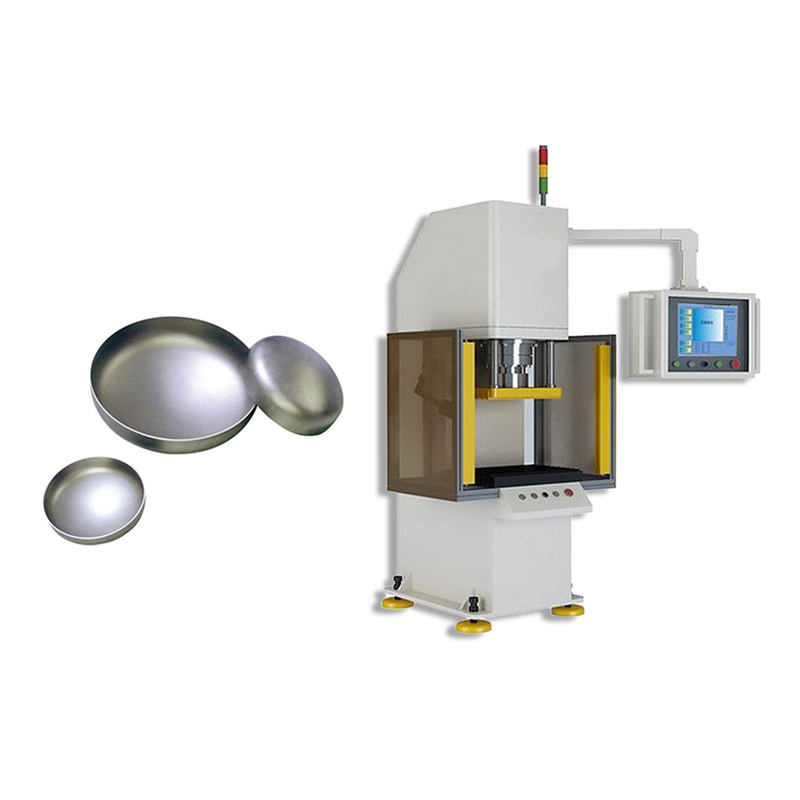

- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

200 kN

-

Place of Origin:

-

Guangdong Dongguan

-

Brand Name:

-

CO-WIN

-

Year:

-

2023

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

1200mm*1300mm*2100mm

-

Weight (T):

-

1 T

-

Motor Power (kw):

-

2 kw

-

Marketing Type:

-

New Product 2023

Quick Details

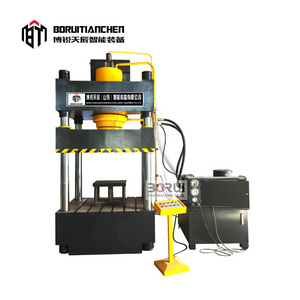

-

Machine Type:

-

Four-column Two-beam Hydraulic Press

-

Slide Stroke (mm):

-

300

-

Ejector Force (kN):

-

200

-

Return Force (kN):

-

200 kN

-

Place of Origin:

-

Guangdong Dongguan

-

Brand Name:

-

CO-WIN

-

Year:

-

2023

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

1200mm*1300mm*2100mm

-

Weight (T):

-

1 T

-

Motor Power (kw):

-

2 kw

-

Marketing Type:

-

New Product 2023

Product Description

Specification

|

Product parameters

|

Standard itinerary

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

|

CW-200

|

100

|

Φ8

|

17

|

10

|

M4*0.7

|

130

|

295

|

508

|

|

CW-500

|

100

|

Φ8

|

31

|

12

|

M8*1.25

|

130

|

290

|

508

|

|

CW-1000

|

100

|

Φ8

|

31

|

12

|

M8*1.25

|

130

|

290

|

508

|

|

CW-2000

|

150

|

Φ8

|

37

|

12

|

M8*1.25

|

200

|

300

|

765

|

|

CW-5000

|

200

|

Φ8

|

40

|

20

|

M8*1.25

|

200

|

300

|

865

|

|

CW-8000

|

200

|

Φ8

|

40

|

20

|

M8*1.25

|

200

|

300

|

925

|

|

H

|

I

|

J

|

K

|

L

|

M

|

N

|

|

1615

|

240

|

Φ40

|

850

|

378

|

330

|

258

|

|

1675

|

240

|

Φ65

|

850

|

378

|

330

|

258

|

|

1675

|

240

|

Φ65

|

850

|

378

|

330

|

258

|

|

1975

|

280

|

Φ80

|

900

|

500

|

480

|

400

|

|

2150

|

320

|

Φ120

|

900

|

500

|

480

|

400

|

|

2280

|

380

|

Φ150

|

900

|

50g

|

480

|

400

|

Remark

:The column locking parameters in the above table are only for selection reference. The actual data is subject to your product description. If there are any changes to the first off parameters, the latest ones shall prevail.

Products Description

Product Features

1) The high-precision feature of achieving precise pressure and displacement full closed-loop control is unmatched by other types of presses;

2) The whole process curve of pressing force and displacement can be displayed on the LCD touch screen; the whole process control can automatically determine whether the product is qualified at any stage during the operation, and remove defective products 100% in real time, thereby realizing online quality management;

3) Pressing force, pressing depth, pressure speed, pressure holding time, etc. can all be entered numerically on the operation panel.

4) You can customize, store and call 100 sets of press-fitting programs; seven press-fitting modes are available to meet your different process needs;

5) By connecting to the computer through the external port, the pressing data can be stored in the computer to ensure the traceability of product processing data and facilitate production quality control and management;

Application

Scope of application:

1. Automotive industry: press-fitting of engine components (cylinder head, cylinder liner, oil seal, etc.) press-fitting of steering gear components, etc.

2. Motor industry: Press-fitting of micromotor components (spindle, casing, etc.) and press-fitting of motor components (bearings, spindle, etc.).

3. New energy industry: graphene, lithium batteries, hydrogen fuel cells (stacks, bipolar plates, membrane electrodes, proton exchange membranes).

4. As well as scientific research experiments, aerospace and military industry, 3C (computers, communications, electronics), press assembly line integration, home appliances and other industries.

Hot Searches