- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

30mm

-

Control Software:

-

CypCut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GoodCut

-

Weight (KG):

-

3300 KG

-

Product name:

-

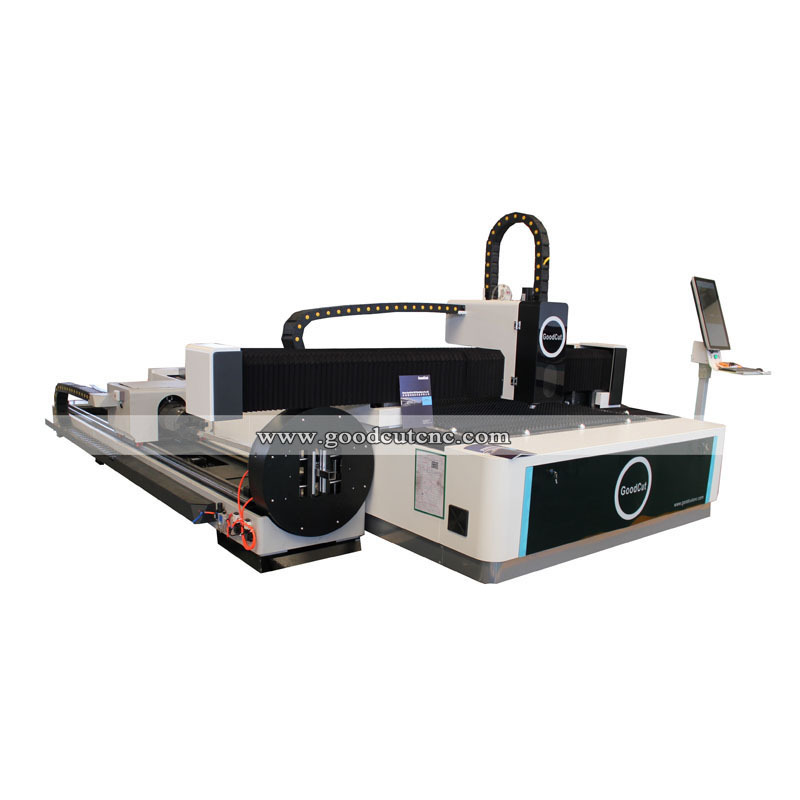

GC1530 fiber laser 1kw cnc pipe laser cutting machine for metal

-

Laser power:

-

1000w 1500w 2000w 2500w 3000w 4000w

-

Laser source:

-

Raycus IPG/ MAX

-

Type:

-

Fiber Lasr Cutting

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Control system:

-

Cypcut Control System

-

Motor driver:

-

Japan FS/Taiwan Delta/Yaskawa servo motors and drives

-

Tube metal cutting:

-

4 Axis Rotary Device

-

Optional:

-

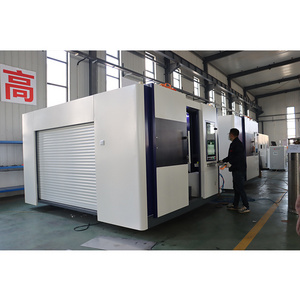

Whole protective cover

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

100m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

30mm

-

Control Software:

-

CypCut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GoodCut

-

Weight (KG):

-

3300 KG

-

Product name:

-

GC1530 fiber laser 1kw cnc pipe laser cutting machine for metal

-

Laser power:

-

1000w 1500w 2000w 2500w 3000w 4000w

-

Laser source:

-

Raycus IPG/ MAX

-

Type:

-

Fiber Lasr Cutting

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Control system:

-

Cypcut Control System

-

Motor driver:

-

Japan FS/Taiwan Delta/Yaskawa servo motors and drives

-

Tube metal cutting:

-

4 Axis Rotary Device

-

Optional:

-

Whole protective cover

GC1530 fiber laser 1kw cnc pipe laser cutting machine for metal

1. Excellent Path Quality: Smaller laser dot and high work efficiency, high quality.

2. High Cutting Speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable Running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High Efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low Maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7. Easy Operations: fiber line transmission, no adjustment of optical path.

Parameters of GC1530 fiber laser 1kw cnc pipe laser cutting machine for metal :

|

Model

|

GC1530R(GC2030R GC2040R GC2060R)

|

|

Working area

|

3000*1500mm

|

|

Miximum length of pipe(Options)

|

3000mm(or)6000mm

|

|

Limits of pipe(Customized) |

Round tube:Φ20mm~Φ120mm;

Square tube :Φ20mm~80mm; Circular tube: Φ20mm~Φ120mm;Square tube: Φ20mm~80mm |

|

Laser type

|

Fiber laser generator

|

|

Laser power(optional)

|

500~4000W

|

|

Transmission system

|

Double serve motor &gantry&rack&pinion

|

|

Maximum speed

|

±0.03mm/1000mm

|

|

Pipe cutting system(optional)

|

yes

|

|

Maximum speed

|

60m/min

|

|

Maximum accelerated speed

|

1.2G

|

|

Position accuracy

|

±0.03mm/1000mm

|

|

Reposition accuracy

|

±0.02mm/1000mm

|

|

Graphic format supported

|

CAD,DXF(etc)

|

|

Power supply

|

380V/50Hz/60Hz

|

Advantages of Best brand metal tube cnc fiber laser pipe cutting machine :

1, High speed, high precision, high efficiency and low cost

2, Easy on operation, fiber optical path, without tediously adjustment on optical path

3, Compact structure, good sealing, strongly adaptable to changes in the environment.

4, With the perfect automatic nesting system which can save time, save the materials, the sheet utilization ratio up to 95%

5.Power off cutting memory function, if power off sudden then start from the break point.

Applications of Best brand metal tube cnc fiber laser pipe cutting machine :

Parts descriptions

Rotary Axis

The rotary axis attachment is for cutting the pipes. Alpha supply two types of rotary axis for option. The first one is with semi-automatic clamp, the second type is with full-automatic clamp.

The semi-automatic clamp need the worker use the hand to fix the pipe on the rotary axis. However, the full-automatic clamp can clamp the pipe automatically.

The semi-automatic clamp price is cheaper, but the full-automatic one is with higher efficiency and higher precision.

The rotary axis clamping diameter range is 20-200mm, the Max. clamping length is 3m.

Laser head with Anti-crash function, Good sealed, high pressure resistant, auto-tracking system and anti-crash and stop system can

protect good cutting quality and longer the life of lens.

Taiwan APEX Gear Rack

Taiwan APEX hight precision rack grade 5 precision

Can be perfect for laser cutting machine.It can provide rigid. Support for quenching bevel gear and grinding belvel gear.

Heavy duty steel welded machine frame

The bed is welded from thick steel pipes. The bed is annealed to eliminate excess hard force, increase the ductility of the bed, and ensure stability during the cutting process.

Japan Shjmpo reducer

Taiwan Hiwin huide rail

Applications industry:

fiber lasers cutting machine including telecommunications, spectroscopy, medicine, and directed energy weapons,Electric power, automobile manufacturing, mechanical equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertisement board, car decoration, sheet metal production, lighting hardware, display equipment, precision parts, hardware products and other industries.

Applicable material: stainles steel, carbon steel, mild steel, iron, galvanized sheet, titanim sheet, copper, aluminum etc.

Jinan GoodCut CNC Machinery Co.,Ltd.

GoodCut has Purchasing department, The design department, The production department, Quality inspection department, packaging and transportation department, The sales department, After sales service department.

We can offer highest quality machine, and competitive price.

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

Good Quality

1. 15 engineers with more than 10 years rich working experience, manufacture high precision machines;

2. Three-day 72-hour testing machine inspection, after confirming that the machine has no quality problems, then it will be shipped;

3. 4 QC staffs do strict evaluations on in-coming inspections, in-process inspections and final inspections.

Good Price

1. GoodCut manufactures about 50 sets of machines per month, with a large sales volume. We have long-term cooperation with parts suppliers, can get advantageous prices of parts, so that the price of machine is very competitive;

2. GoodCut aims to develop long-term cooperation with new and regular customers, and to give customers the best prices with the most sincere attitude.

Good Service

1. English manual and video for machine using and maintaining, explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching to eliminate customer worries.