Control System

CNC touch screen system. Easy setting with the automatic processing function. Make machining job easy, high efficient.

|

Model

|

unit

|

WZQJ-5N

|

||

|

Longitudinal X stroke

|

mm

|

3200

|

||

|

Lateral Y stroke

|

mm

|

2000

|

||

|

The Z axis saw blade blade vertical stroke

|

mm

|

350

|

||

|

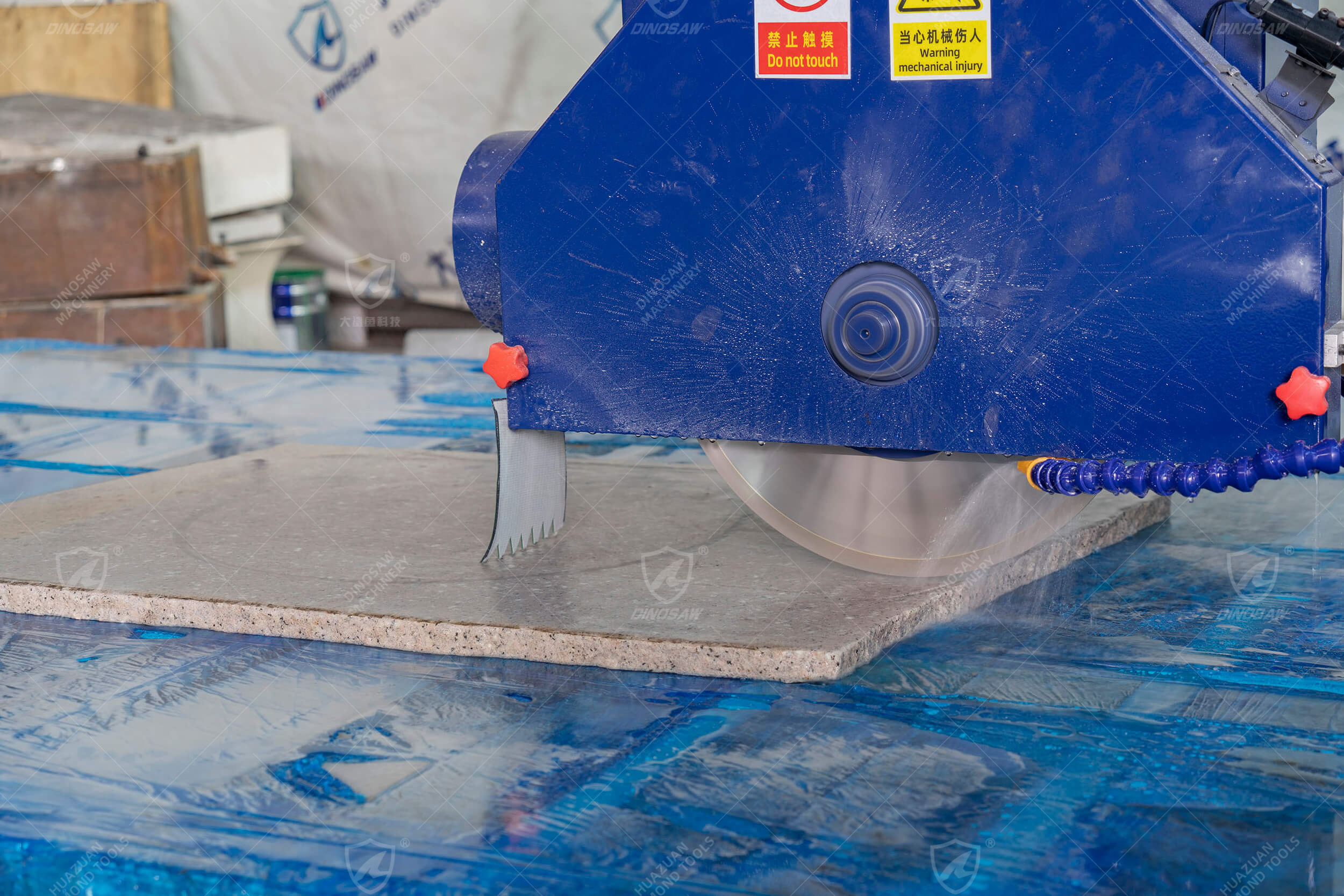

Max.Saw blade diameter

|

mm

|

600

|

||

|

Max. Cutting depth

|

mm

|

180

|

||

|

Blade tilted angle

|

n°

|

0-360

|

||

|

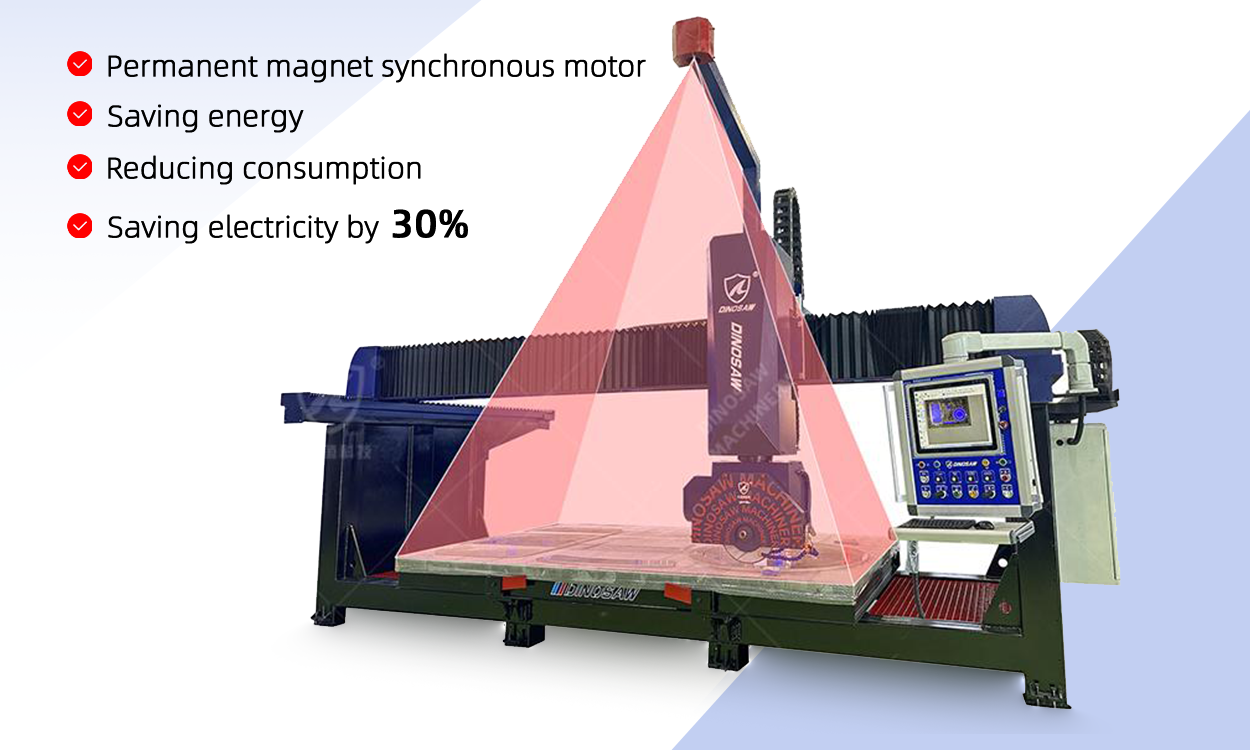

Spindle motor capacity

|

kw

|

18.5

|

||

|

Table dimensions(L*W)

|

mm

|

3200*2000

|

||

|

Worktable tilting degress(optional)

|

n°

|

0-85°

|

||

|

Overall dimension(L*W*H)

|

mm

|

5500*3000*55000

|

||

|

Weight

|

kgs

|

4600

|

||

|

*It can be customized according to customers’ requirement

|

|

|

||