Capacity:5 tons

Coil inner diameter:450-550mm

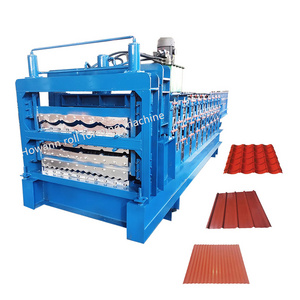

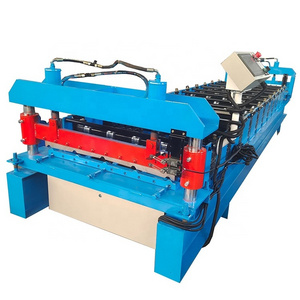

Feeding width: max 1250mm

Function:Uncoiling follows the speed of the machine by the traction of the machine

Coil inner diameter:450-550mm

Feeding width: max 1250mm

Function:Uncoiling follows the speed of the machine by the traction of the machine