- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

380V / 220V or customized

-

Weight:

-

3500 kg

-

Feeding width:

-

1000-1250mm

-

Marketing Type:

-

New Product

-

Product name:

-

Double Layer Roll Forming Machine

-

Keywords:

-

Double Layer Roll Forming Machine

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45roll forming machinery Steel Plated

-

Working principle:

-

Electric

-

Raw material:

-

Glazed Tile

-

Color:

-

Customized

-

Usage:

-

Wall Roof Panel

-

Material:

-

Glazed Tile

-

After-sales Service Provided:

-

Online Support Video Technical Support

Quick Details

-

Type:

-

Roll Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

380V / 220V or customized

-

Weight:

-

3500 kg

-

Feeding width:

-

1000-1250mm

-

Marketing Type:

-

New Product

-

Product name:

-

Double Layer Roll Forming Machine

-

Keywords:

-

Double Layer Roll Forming Machine

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45roll forming machinery Steel Plated

-

Working principle:

-

Electric

-

Raw material:

-

Glazed Tile

-

Color:

-

Customized

-

Usage:

-

Wall Roof Panel

-

Material:

-

Glazed Tile

-

After-sales Service Provided:

-

Online Support Video Technical Support

Products Overview

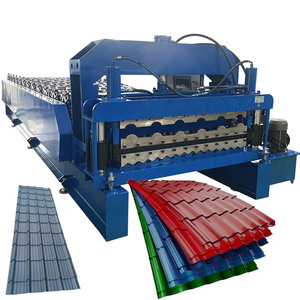

Glazed Corrugated Tile Roof Roll Forming Machine 800+850mm

Roll forming machine is a machine composed of feeding, forming and post-forming cutting. Its color plate appearance is smooth and beautiful, uniform paint pattern, high strength and durable. It is widely used in industrial and civil buildings, such as factory buildings, warehouses, stadiums, exhibition halls, theaters and other rooms and walls.

Color profiled steel plate is a profiled plate that adopts color coating steel plate and is rolled and cold-formed into various wave shapes. It is suitable for industrial and civil buildings, warehouse special buildings, and large-span steel structure houses. Wall decoration, etc., has the characteristics of light weight, high strength, rich color, convenient and fast construction, earthquake resistance, fire resistance, rain resistance, long life, and maintenance-free. It has been widely promoted and applied.

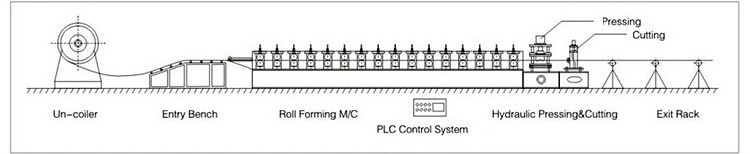

Working Process :

Decoiler—Roll Forming Machine——Hydraulic Press——Hydraulic cutter——Control System——Receiving table

Specification

|

Item

|

Description

|

|

Applicable materials

|

Colored glazed steel

|

|

Feeding width

|

1000-1200mm

|

|

Effective width

|

800-1000mm

|

|

Material thickness

|

0.3-0.8mm

|

|

Number of rollers

|

13rows/9 roller

|

|

Frame size

|

350H section steel (national standard)

|

|

Middle plate thickness

|

16mm

|

|

Roller material

|

45 # steel

|

|

Roller diameter

|

Roller diameter

|

|

Drive servo motor

|

5.5KW

|

|

Oil pump power

|

4KW(Large box + cooling air box)

|

|

Tool material

|

Cr12

|

|

Voltage

|

380v,50hz,3 phase

|

|

Cutting accuracy

|

±2 mm

|

|

PLC panel

|

touch screen electric control cabinet

|

|

Outside dimension

|

L*W*H=6500mm*1500mm*150mm

|

|

Forming speed

|

Glazed tile 2m/min Common 10-15m/min

|

Noted:

There are two types of roll forming machines:

standard type and customized type.

If you need to customize, please send us

the design drawing,feeding width, thickness and raw materials

, so that we can customize according to your requirements, which is very important for us!!!

Why Choose Us

♥ Over 20 years of experience.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in Chile,Brazil, the Philippines, Malaysia, India, and other countries

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in Chile,Brazil, the Philippines, Malaysia, India, and other countries

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

Our Technical Personnel Provide On-Site Services Overseas:

Our technical personnel arrive at the customer's site in Malaysia for technical guidance and training,If a customer encounters technical problems that are difficult to solve during use, we usually send professional and technical personnel to foreign customer sites for guidance and training. Therefore, if you want to do business in cold bending forming equipment, please feel free to contact our customer service personnel at any time.

Our technical personnel arrive at the customer's site in Malaysia for technical guidance and training,If a customer encounters technical problems that are difficult to solve during use, we usually send professional and technical personnel to foreign customer sites for guidance and training. Therefore, if you want to do business in cold bending forming equipment, please feel free to contact our customer service personnel at any time.

Product Application

Roll forming machine manufacturers is mainly producing steel roof/ wall sheet .The final products have too many types,corrugated sheet and trapezoidal sheet.As we know, steel roof/ wall sheet is widely used in large span factory building, warehouse, office buildings, villas, roof, cold storage, air purification room, stores, kiosks, and temporary housing.

Product packaging

Hot Searches