- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

/

-

Voltage:

-

380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Higheasy

-

Dimension(L*W*H):

-

250x225x180mm

-

Weight:

-

2tons

-

Product name:

-

Sealing Machine

-

Certification:

-

/

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

/

-

Voltage:

-

380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Higheasy

-

Dimension(L*W*H):

-

250x225x180mm

-

Weight:

-

2tons

-

Product name:

-

Sealing Machine

-

Certification:

-

/

Fully automatic spout inserting welding machine

I. Introduction

Flexible pouch auto spout sealing machine is one kind of automatic device to install and seal plastic spout with pouch. Pouch with spout is manufactured by this machine with advantage of high production efficiency, good looking, high sealing strength, avoiding human to touch spout and pouch, safe and sanitary.

FZJ-12-70 flexible pouch auto spout sealing machine has function of auto spout location and multi-stations transmission, pouch loading with spout and sealing. Suitable for long spout and short spout, vertical type sealing spout.

II. Component

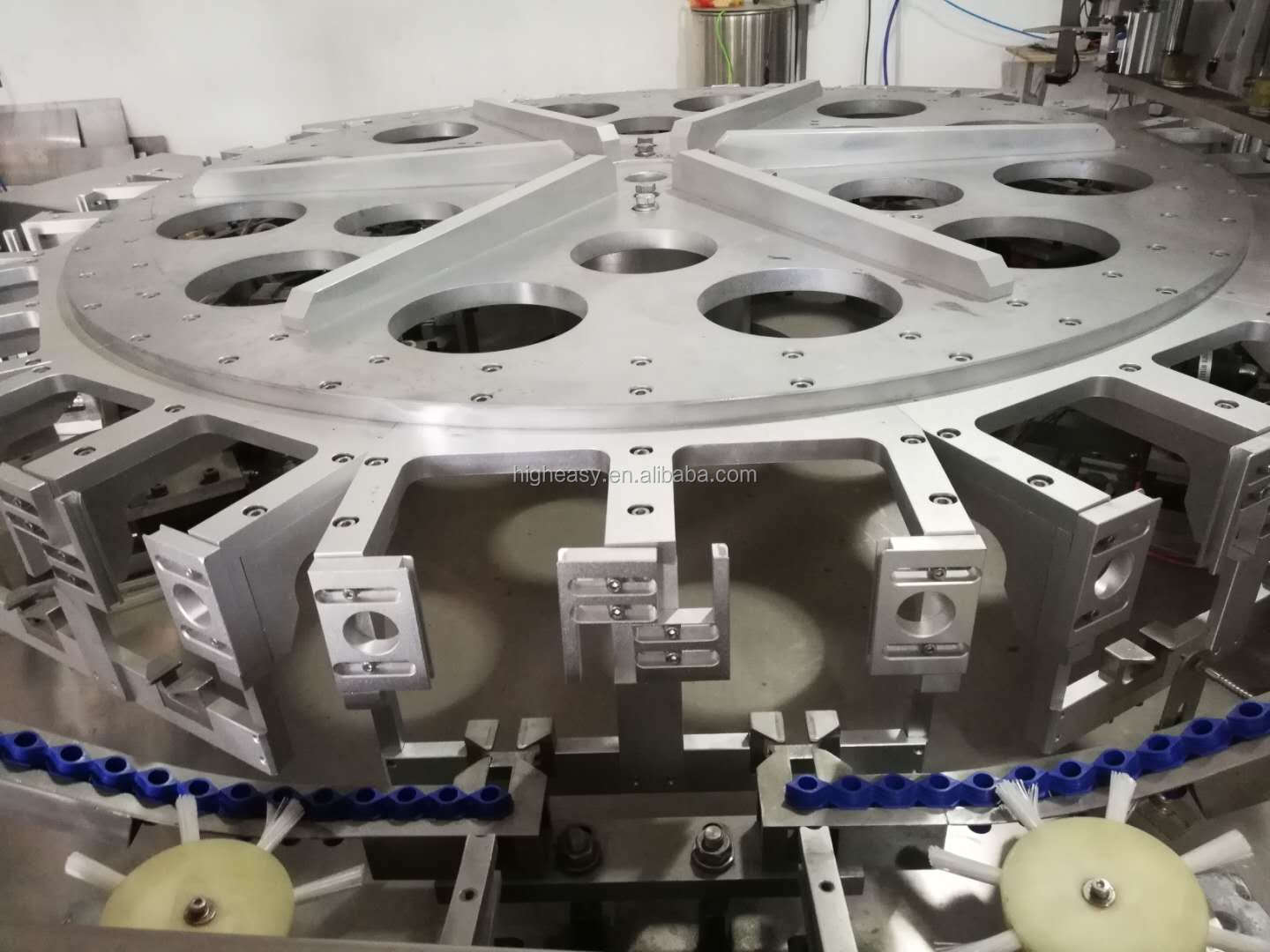

1. Vibration plate auto spout loading system: this system is composed of photoelectric control storage and vibration plate, can automatically transmit plastic spout to spout loading device. Vibration plate can store 500pcs of spout.

2. Spout loading system: adopts three-axis cylinder instead of former one-axis cylinder, push spout into groove of conveyor, auto location, no angle changing, ensure product accuracy.

3. Transfer system: Transfer spout or pouch according to station fixed length, in order for spout loading, spot welding, hot sealing, cold shaping, detection functions. Transfer system is drove by Mitsubishi servomotor.

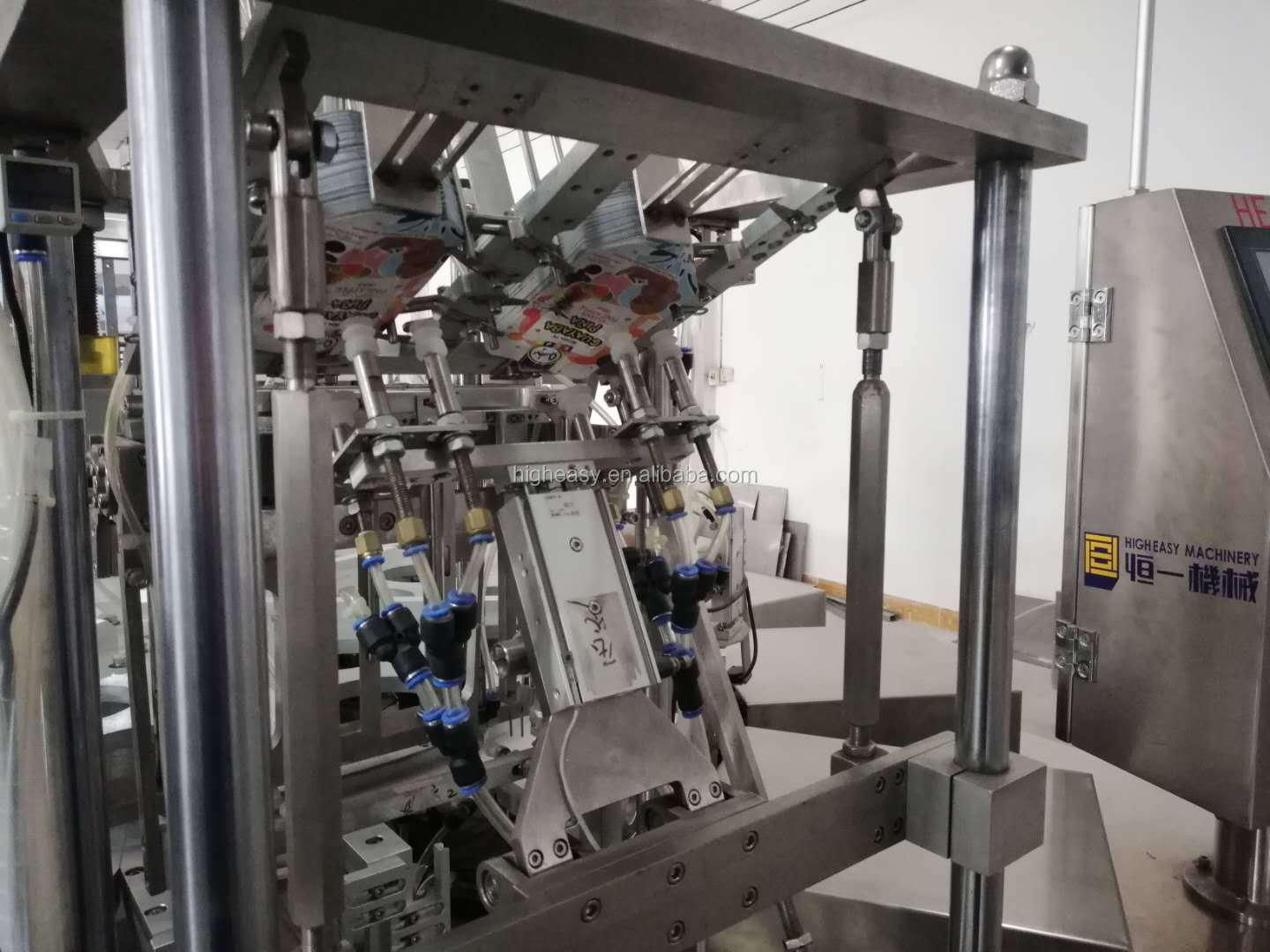

4. Pouch loading system is composed of pouch storehouse, pouch pick-up device, pouch loading device. Used for pick-up from pouch storehouse, pouch clamping, pouch opening, spout loading and spot seal, then transfer to next step.

5. Multi-sealing system: composed of multiple heat sealing cylinder group for each process such as one-time pre-heat, four times heat sealing and one-time cold shaping.

6. Optical detection system: auto detect spout-sealing quality, remove defective product, defective percentage less than 5‰.

7. Finished product loaded on groove-stick and auto reload system: finished products will be loaded into groove-stick after counting for filling machine use, groove-stick auto discharging after full load.

III. Main technical specifications

|

Model |

FZJ-12-70 |

|

Pouch dimension |

L×W(70-230)×(60-120)mm |

|

Spout inner size |

8.2mm or 8.6mm or 10mm, 13mm Custom-made |

|

Capacity |

40-80pcs/min(70pcs/min can be very stable) |

|

Power supply |

AC380V, 50HZ, 3P, 8.0KW |

|

Air supply |

0.5-0.7MPa 180NL/min |

|

Chilling water |

6L/min |

|

Machine dimension |

(L×W×H) Major machine: 2480×2280×1800mm Auto pouch discharging device: 1300*820*1700mm |

|

Weight |

2300KG |