- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Xintao

-

Product name:

-

High Alumina White Ceramic Balls

-

Color:

-

White

-

Shape:

-

Round

-

Al2O3(%):

-

95%

-

Moh's Hardness Scale:

-

>8.0

-

Max. Operating Temperature:

-

1550℃

-

Specific Density:

-

3400kg/m3

-

Bulk density:

-

2000kg/m3

-

Warranty:

-

3-5 years

-

Sample:

-

500g for free

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Jiangxi, China

-

Model Number:

-

92% Ceramic Ball

-

Brand Name:

-

Xintao

-

Product name:

-

High Alumina White Ceramic Balls

-

Color:

-

White

-

Shape:

-

Round

-

Al2O3(%):

-

95%

-

Moh's Hardness Scale:

-

>8.0

-

Max. Operating Temperature:

-

1550℃

-

Specific Density:

-

3400kg/m3

-

Bulk density:

-

2000kg/m3

-

Warranty:

-

3-5 years

-

Sample:

-

500g for free

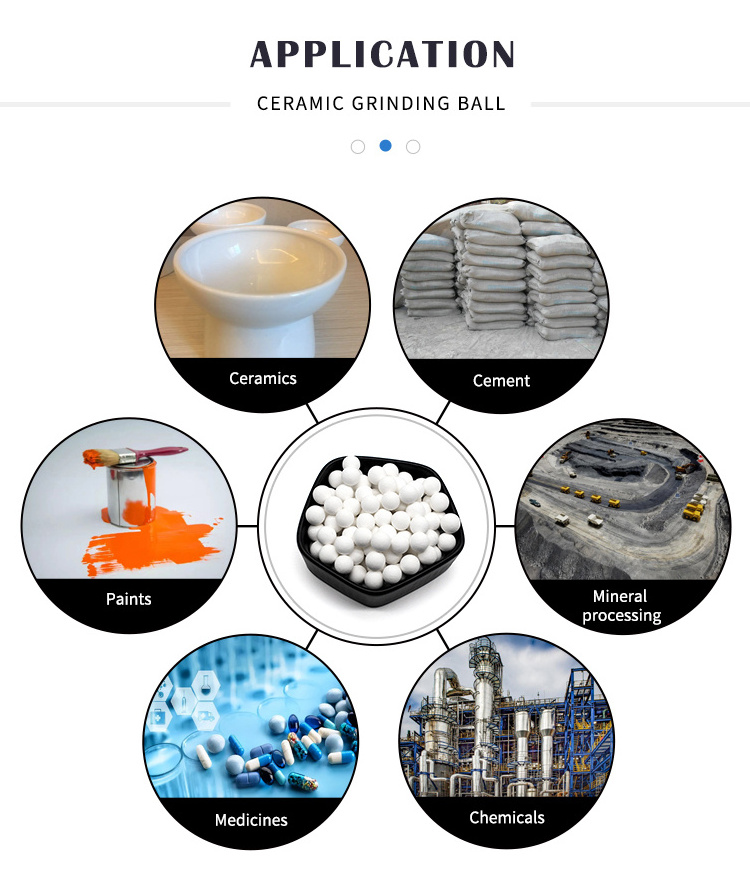

high alumina corundum grinding ball polishing media 92% ceramic balls for ball mill

Technical Data:

|

Product |

Al2O3% |

Bulk density g/cm2 |

Water absorption% |

Mohs Hardness scale |

Abrasion loss% |

|

High Alumina Grinding Balls |

92 |

3.65 |

0.01 |

9 |

0.011 |

|

95 |

3.68 |

0.005 |

9 |

0.0084 |

|

|

Appearance Demand |

|||||

|

Crack |

Not Permission |

Not Permission |

Not Permission |

||

|

Impurity |

Not Permission |

Not Permission |

Not Permission |

||

|

Foam hole |

Above 1mm not permission, size in 0.5mm permit 3 balls |

||||

|

Flaw |

Max. size in 0.3mm permit 3 balls |

||||

|

The standard specification |

3~50mm or customized. |

||||

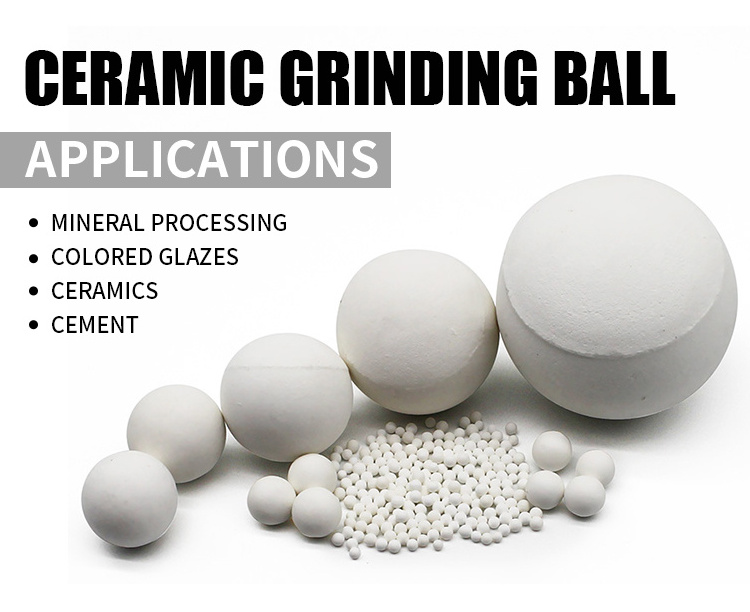

Advantage:

(1) High wear-resistance: The alumina balls wear-resistance is higher than the common alumina balls. When it is working, the ball won’t pollute the grinding materials, so it can keep the purity and improve the stability of grinded materials especially the ceramic glaze.

(2) High density: The high density, high hardness and the high grinding characters save the grinding time, enlarge the smashing room. So it can improve the grinding efficiency.