- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ZD

-

Model Number:

-

ZD-SCD-45

-

Voltage:

-

380/220V

-

Dimension(L*W*H):

-

5600*1800*1200mm

-

Weight:

-

2200 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Max feeding size:

-

1200*800mm

-

Printing speed:

-

25-45pcs/min

-

Diameter of unwinding cloth:

-

below 1200mm

-

After-sales Service Provided 1:

-

Online support

-

After-sales Service Provided 2:

-

Video technical support

-

After-sales Service Provided 3:

-

Free spare parts

-

After-sales Service Provided 4:

-

Field installation, commissioning and training

-

After-sales Service Provided 5:

-

Field maintenance and repair service

Quick Details

-

Machine Type:

-

Sewing Machine

-

Bag Type:

-

Cement Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ZD

-

Model Number:

-

ZD-SCD-45

-

Voltage:

-

380/220V

-

Dimension(L*W*H):

-

5600*1800*1200mm

-

Weight:

-

2200 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Max feeding size:

-

1200*800mm

-

Printing speed:

-

25-45pcs/min

-

Diameter of unwinding cloth:

-

below 1200mm

-

After-sales Service Provided 1:

-

Online support

-

After-sales Service Provided 2:

-

Video technical support

-

After-sales Service Provided 3:

-

Free spare parts

-

After-sales Service Provided 4:

-

Field installation, commissioning and training

-

After-sales Service Provided 5:

-

Field maintenance and repair service

Product Description

|

Item

|

ZD-SCD-45

|

|

Max.Diameter of cloth roller (mm)

|

1200mm

|

|

Cutting length (mm)

|

600-1200mm

|

|

Folding width (mm)

|

20-30mm

|

|

Gross power (kw)

|

6KW

|

|

Stitch range

|

3.6-8mm

|

|

Max.cutting width (mm)

|

800mm

|

|

Cutting precision (mm)

|

±1.5mm

|

|

Production capacity (PCS/m)

|

25-45pcs/min

|

|

Weight (kg)

|

(About) 2200kg

|

|

Machine size (LxWxH) (mm)

|

5600 x1800 x1200mm

|

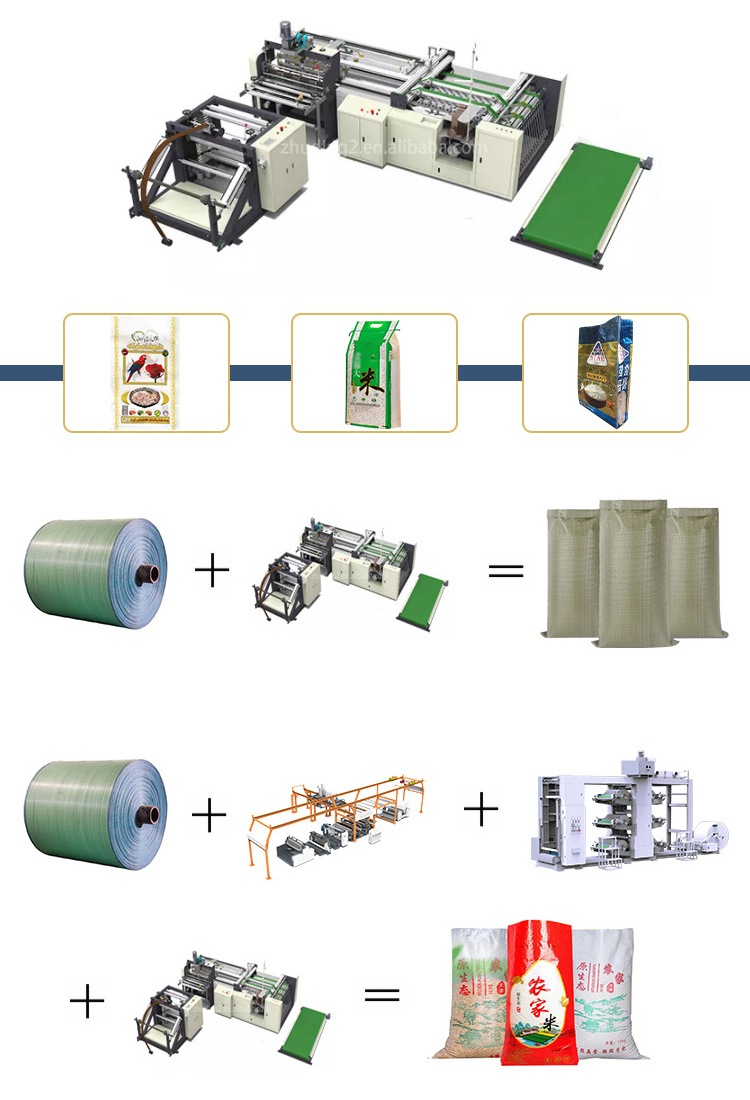

PRODUCT INTRODUCTION:

1. It can automatically accomplish the fixed-length thermal cutting and the bottom hemming for the woven cloth in roll,which saves labor forces.

2. It adopts the servo motor to drive, and the optical code meter to count the length, which precisely controls thelength ofbags.

3. After the heat cutting, the plackets of bags are easy to open, not conglutinated.

4. Pneumatic up-coiling, theoperation is convenient.

5. Two working position for circulation transferring by magnet gripper.

6. Servo controlling for cutting accuracy.

7 .High-speed cutting accuracy.

8. Heat cutting with bag mouth open system equipped.

9. Edge position control(EPC)for unwinding.

10. PLC Operation control, digital display for operation monitor and operation setting.

3. After the heat cutting, the plackets of bags are easy to open, not conglutinated.

4. Pneumatic up-coiling, theoperation is convenient.

5. Two working position for circulation transferring by magnet gripper.

6. Servo controlling for cutting accuracy.

7 .High-speed cutting accuracy.

8. Heat cutting with bag mouth open system equipped.

9. Edge position control(EPC)for unwinding.

10. PLC Operation control, digital display for operation monitor and operation setting.

1. Q:How long will your engineer reach our factory?

A:Within one week after everything ready (machine arrival your factory, nonwoven material, power source, air compressor etc.Prepared).

2. Q:How many days will you finish installing ?

A:We will finish installation and training within 15 days.

3. Q:What should we charge for your engineer?

A:You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary 80USD one day per person.

4. Q:How long is your machine's warranty period?

A: All our machine have half a years guarantee for electricity parts and one years guarantee for mechanism, starting from finished installation.

5. Q:How could you do if the parts broken within warranty?

A: We would express the free replacement parts during the warranty date.

6. Q:How could you do after one year warranty period?

A:We also can do service for you, but you need pay salary for our technicians 80USD/day for each person.

7. Q:Does your engineer understand English?

A:Our engineers understand a little English. All our engineers have more than five years machine installation experience.

8. Q:Can you help us find any engineer in our location?

A:Of course, we will check and inform you as soon as possible.

9. Q:How do we solve the machine problem after your engineer leaving?

A:Generally speaking, there will be no problem after finishing installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according your description.

2. Q:How many days will you finish installing ?

A:We will finish installation and training within 15 days.

3. Q:What should we charge for your engineer?

A:You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary 80USD one day per person.

4. Q:How long is your machine's warranty period?

A: All our machine have half a years guarantee for electricity parts and one years guarantee for mechanism, starting from finished installation.

5. Q:How could you do if the parts broken within warranty?

A: We would express the free replacement parts during the warranty date.

6. Q:How could you do after one year warranty period?

A:We also can do service for you, but you need pay salary for our technicians 80USD/day for each person.

7. Q:Does your engineer understand English?

A:Our engineers understand a little English. All our engineers have more than five years machine installation experience.

8. Q:Can you help us find any engineer in our location?

A:Of course, we will check and inform you as soon as possible.

9. Q:How do we solve the machine problem after your engineer leaving?

A:Generally speaking, there will be no problem after finishing installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according your description.

Hot Searches