- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

420*215*110cm

-

Power (kW):

-

18.5

-

Weight (KG):

-

5500

-

Cutting material:

-

Steel Billet

-

Type:

-

Rebar Cutting Machine

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

WILA

-

Voltage:

-

220V/110V

-

Dimension(L*W*H):

-

420*215*110cm

-

Power (kW):

-

18.5

-

Weight (KG):

-

5500

-

Cutting material:

-

Steel Billet

-

Type:

-

Rebar Cutting Machine

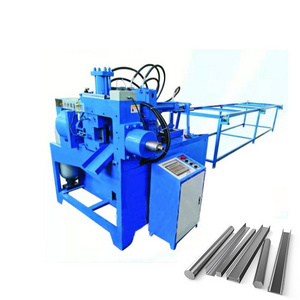

Automatic round steel bar cutting line

(it could cut 32,40,50,65,80mm Round steel rod)

Features:

1. It adopts fully automatic feeding rack, no need for manual feeding, turning and feeding, one person with multiple machines. Reduce labor intensity and save cost.

2. Professional double metal sliding guide, anti-wear, durability and good

3.Fully enclosed clamshell knife mold, easy to change the knife, 360 degree rotation, repeated use, longer service life

4. reinforced gear alloy steel production, standardizing heat treatment, transmission torque

5. Reasonable retaining design makes the size of the blanking more accurate, the weight deviation is smaller, and the section flatness is higher

6.Reasonable design of retaining mechanism to make the size of blanking accurate and easy to adjust

7.The equipment adopts automatic centering device, cutting round steel of different diameters without adjusting the height of the feeding frame

8.Professional bimetal sliding guide, good wear resistance and durability

9.Guide rail lubrication automatic oil pump added, automatic alarm for oil cut

|

Model

|

WL-32

|

WL-40

|

WL-50

|

WL-65

|

LJX-80

|

|

Cut-off capacity(mm)

|

φ32

|

φ40

|

φ50

|

φ65

|

φ80

|

|

Cutting capacity(s/min)

|

70

|

45

|

32

|

28

|

25

|

|

Keep-off range(mm)

|

20-300

|

20-300

|

20-300

|

20-200

|

35-150

|

|

Screw feeding accuracy

|

≤2

|

≤2

|

≤2

|

≤2

|

≤2

|

|

The section roundness

|

0.95

|

0.95

|

0.95

|

0.95

|

0.95

|

|

Shear weight error(g)

|

±0.5

|

±1

|

±2

|

±3

|

±5

|

|

Motor(kw)

|

3

|

5.5

|

7.5

|

11

|

18.5

|

|

Weight(kgs)

|

800

|

1500

|

2000

|

3000

|

5500

|

to each refueling point, which is convenient and practical, and eliminates the hidden danger of wear caused by lack of oil.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* Visa invitation and View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Email:sales1@wilacnc.com

Whatsapp NO:+8613956232507

Wechat/phone:+8613956232507

http://www.wilacnc.com