- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

INNOVACERA

-

Color:

-

White,black,coffee

-

Density:

-

≥3.64g/cm3

-

Flexural strength:

-

336.1MpaMpa

-

Compressive strength:

-

287Mpa

-

Thermal Conductivity:

-

35w/mk

-

Hardness:

-

2 Moh's

-

Volume Resistivity:

-

0^8~10^13

-

Shape:

-

Customised

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

INCPO-001

-

Brand Name:

-

INNOVACERA

-

Color:

-

White,black,coffee

-

Density:

-

≥3.64g/cm3

-

Flexural strength:

-

336.1MpaMpa

-

Compressive strength:

-

287Mpa

-

Thermal Conductivity:

-

35w/mk

-

Hardness:

-

2 Moh's

-

Volume Resistivity:

-

0^8~10^13

-

Shape:

-

Customised

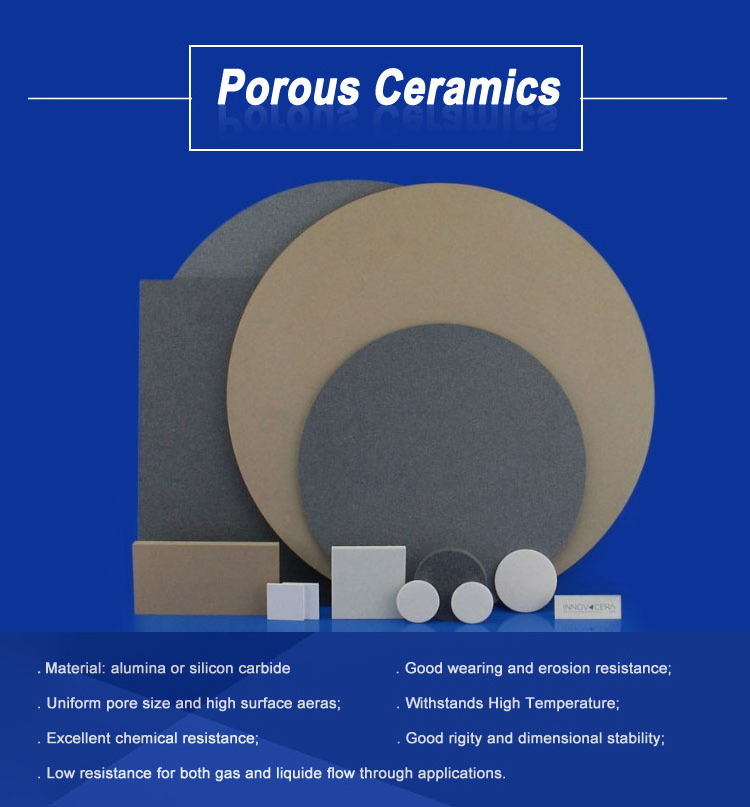

100um OD2mm 3.5mm Alumina Micro Porous Ceramic Wick

Porous ceramic filter plate are composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process.

* Good electrical insulation

* High dimensional tolerances

* Excellent corrosion resistance

* Very high working temperatures

* Excellent thermal shock properties

Applications of

Alumina Porous Ceramic

- Furnace work tubes

- Kiln furniture, components & accessories

- Thermocouple protection tubes

- Heater Support Elements

- High Temperature Electrical Insulators

- Extreme temperature measurement components

- Ceramic Laser components

- High voltage electrical insulators

|

Properties

|

Unit

|

Pore Ceramic

|

|

Al2O3 Content

|

wt%

|

≥ 80

|

|

SiO2 Content

|

wt%

|

16-18

|

|

Density

|

g /cm3

|

2.3—2.5

|

|

Hardness (HRA)

|

HRA ≥

|

50

|

|

Flexure strength

|

MPa ≥

|

40

|

|

Compressive Strength

|

MPa≥

|

600

|

|

Porosity Factor

|

%

|

40

|

|

Work Pressure

|

MPa ≤

|

10

|

|

Acid Resistance

|

mg/cm2 ≤

|

10

|

|

Alkali Resistance

|

mg/cm2 ≤

|

20

|

FAQ

---

You can send your drawing with technology requiremens,and infrom your purchase quantity .If you can,pls inform what is your part used in .We will confirm what is the most suitable materials and quote our best price to you in 24 hour

Q2:Can you provide the free samples ?

Yes,we can provide the sample free of charge if we have the stock product as customer's required,but the courier fee be collected.

Q3:How long will it take for you to send me a quote?

This depends on the complexity of your requirements. For simple items such as plates and rods, we can generally supply a quotation within 24 hours.

Q4:What's the delivery time?

For the standard products, like ceramic substrate and insulating rods, delivery time is normally 7 working days. For hot pressed boron nitride and machinable glass ceramic, it's about 10 working days. For customized products made of alumina, zirconia, boron carbide and silicon nitride, total producing time is about 30-45 working days.

Q5:How to contact us ?

You can send the email to sales@innovacera.com

Call to +86 0592-5589730

Q6:More detail company information ?

www.innovacera.com