- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

king machine

-

Dimension(L*W*H):

-

1.2*1.2*1.8M

-

Weight:

-

2500KG

-

Certification:

-

CE,ISO,SGS

-

Product name:

-

Professional complete beer canning system for beer canner

-

Filling temperature:

-

3-5 degree

-

Machine material:

-

Stainless Steel SUS304/SUS316

-

Producing capacity:

-

1000-38000BPH

-

Control:

-

PLC

-

PLC Brand:

-

MITSUBISHI

-

Function:

-

Filling Machine

-

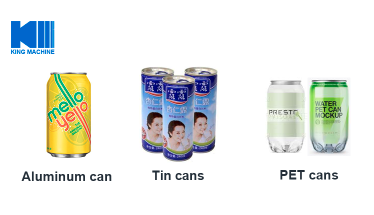

Bottle type:

-

PET Can / Aluminum can

-

Keywords:

-

canning system

Quick Details

-

Packaging Material:

-

Plastic, Metal

-

Voltage:

-

380v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

king machine

-

Dimension(L*W*H):

-

1.2*1.2*1.8M

-

Weight:

-

2500KG

-

Certification:

-

CE,ISO,SGS

-

Product name:

-

Professional complete beer canning system for beer canner

-

Filling temperature:

-

3-5 degree

-

Machine material:

-

Stainless Steel SUS304/SUS316

-

Producing capacity:

-

1000-38000BPH

-

Control:

-

PLC

-

PLC Brand:

-

MITSUBISHI

-

Function:

-

Filling Machine

-

Bottle type:

-

PET Can / Aluminum can

-

Keywords:

-

canning system

Different types can

Different types packaging

Main Machine in Can juice drink hot filling line.

1/Juice Preparing System

2/Water Treatment Syatem

3/Empty can unloading machine

4/Slide - type empty tank spray washer

5/Can juice filling sealing 2 in 1 monoblock

6/Spray sterilizing chiller (including local control cabinet and electrical control device)

7/Wrapping machine

Filling heads.

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

<5>Efficient spray nozzle rinse thoroughly and save water for flushing

Capping heads.

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

<5>Capping effect is stable and reliable ,Defective rate ≤0.2% .

Flat conveyor.

1/Energy saving. High efficient. Adapt to customer factory layout

2/Special lubrication system, keep products clean, health, safety

3/Extended service life

4/Electric eyes design keep whole line running safety and quickly

5/Overload protection mechanism to effectively ensure the safety of the machine

Pre-process system.

1 High-shear emulsifying tank + Plate heat exchanger

2 Mixing tank

3 UHT sterilizer + homogenizer machine + Buffer tank

4 Hot water system + Hot water tank

5 CIP cleaning system

Water treatment system.

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

Turnkey brewery beer brewing equipment 500L 1000L 1500L 2000L 3000L 5000L.

Beer Brewery equipment is used for lab ,pub,bar,hotel,restaurant,industry brewery etc. from 50L to 30000L per day. Brewing process inlcude Milling, mashing, lauterung, boiling, whirlpool, wort chilling, fermentation&maturing, cooling, temperature controlling, cleaning, filling etc..So complete beer brewing equipment including brewhouse, fermentation tanks, bright beer tank, glycol system, controlling system, beer filling machine ect.We can provide the design solution from drawing until after installation.

Empty can unloading machine.

This machine is based on the introduction of foreign advanced technology, combined with the new products developed after years of production experience.

This machine design science is reasonable, modelling is beautiful.

Convenient operation and maintenance, high degree of automation.

This machine is mainly used in the unloading process of the can.

Slide - type empty tank spray washer.

1/Scope of application: water spraying and drying on the slope of the tin can.

2/water spraying box made by stainless steel structure.

3/the built-in ¢32 mm stainless steel spray pipe, divide into two segments, hot and cold water tank temperature higher than 85 degrees.

4/tank cage, by ¢article 8 mm stainless steel.

5/the support frame is composed of 50mm x 50mm x 2mm stainless steel square pipe.

Spray sterilizing chiller

including local control cabinet and electrical control device

1/Mainly for cooling and sterilization

2/The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and observation

3/Nozzles are manufactured using U.S. technology and spray water evenly

4/Conveyor belt adopts Rexnor technology, flat surface with small wear

Bottle packaging machine.

1/PE film shrink wrapping machine

2/Half-tray shrink wrapping machine

3/Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

Zhangjiagang King Machine Co.,Ltd

1 / Standardized workshop of total 20,000 square meters.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

King Machine Sales Manager Team and Engineer Team.

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

King Machine Cetificates and Patents.

International certification, National Certificate of equipment verification, and more than 30 invention patents are done in King machine .

Verification Certificates of equipments:

ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark registration, etc.

HOW TO FIND KING MACHINE?

Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

Visit exhibition in different countries

Send King Machine an request and tell your basic inquiry

King Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

If we can fullfill your request and you interested in our products, you may pay a visit to King Machine site

The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

By letter of credit, you can lock the delivery time easily.

After the factory visit, You can ensure the facticity of our bank account.

SEE KING MACHINE HOW TO ENSURE THE QUALITY!

In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

Each component before assembly needs strictly control by inspecting personnel.

Each assembly is in charged by a master who has working experience for more than 5 years

After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF KING MACHINE!

After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

After the commissioning, we will package the equipment by standard export package for shipment.

According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.