Machine Feature

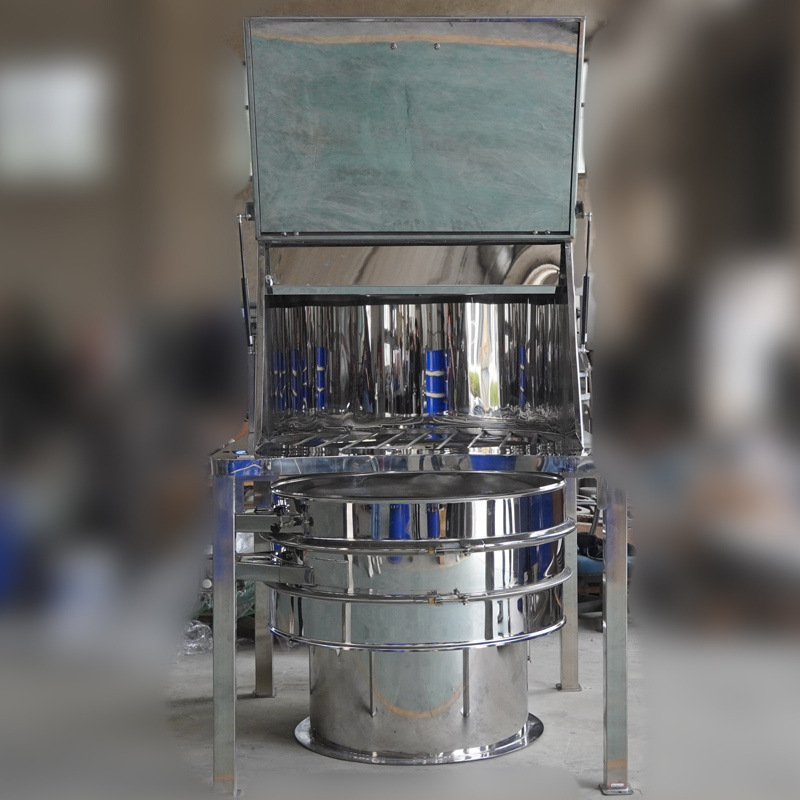

1. It is not easy to blocking material, which also can choose dust collector to reduce dust flying to protect environment.

2. The activated hopper is installed at the bottom of the storage tank, and it can be selected according to the size of storage bin.

3. It solves the problem of blocking of elastic granules and powders and has good durability.

4. The net of vibrating screen is easy to replace, convenient to clean (optional).

5. No dust leakage during operation combined with dust-precipitating system.

6. Set grille to prevent the contact between the PE bag and powder effectively.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sanyuantang

-

Material:

-

304 Stainless Steel

-

Certification:

-

CE, ISO

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

260

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sanyuantang

-

Material:

-

304 Stainless Steel

-

Certification:

-

CE, ISO

Products Description

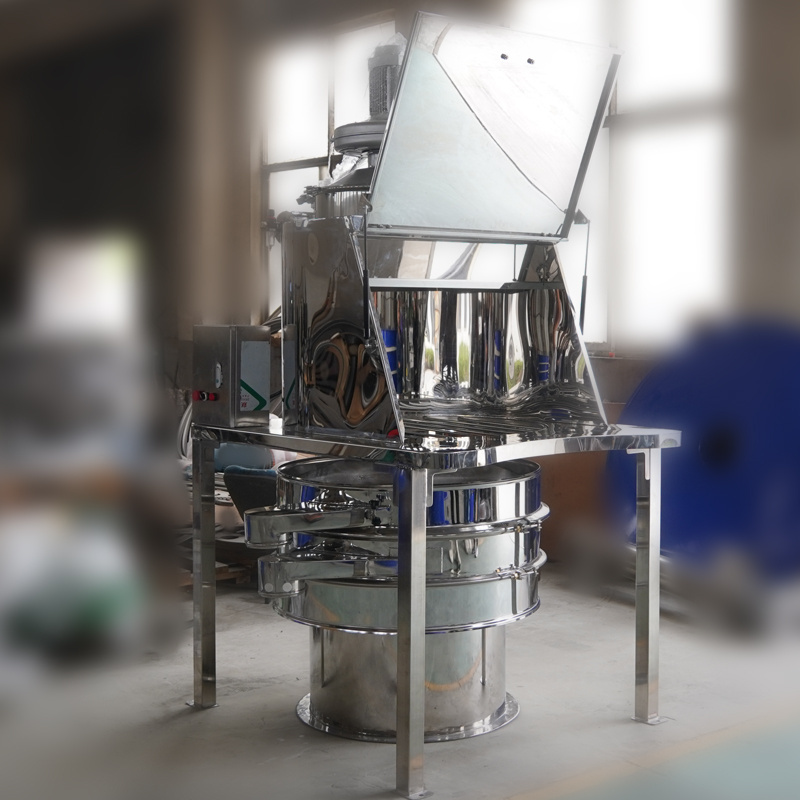

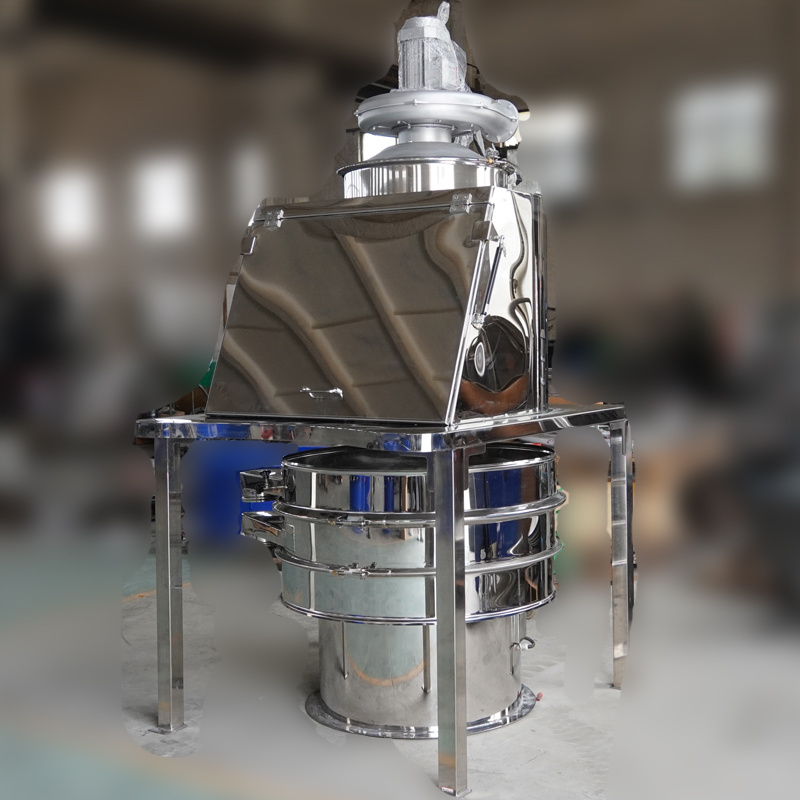

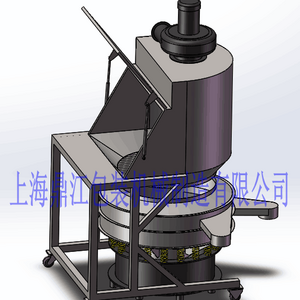

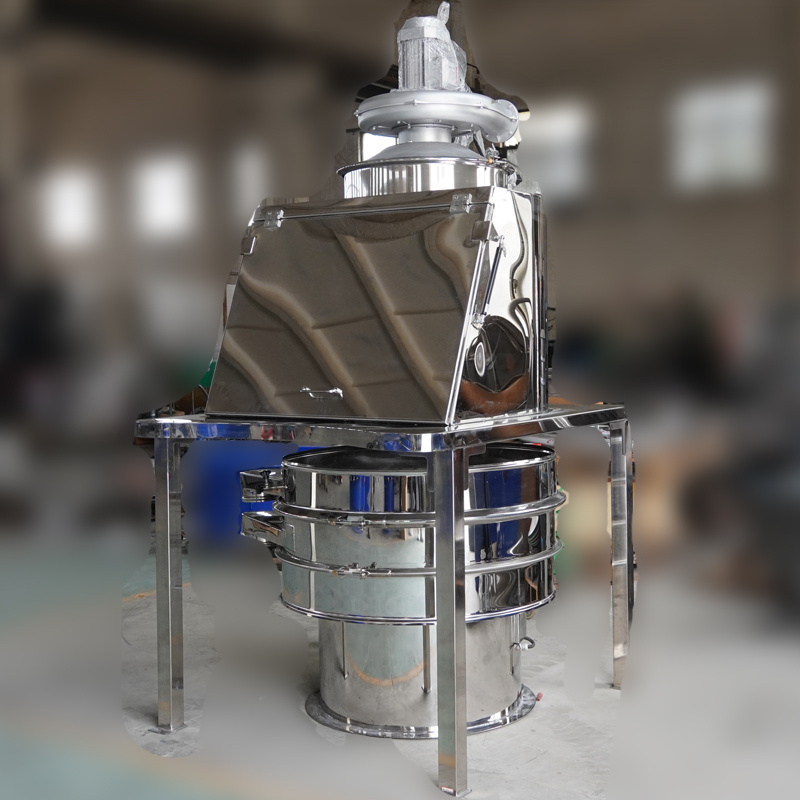

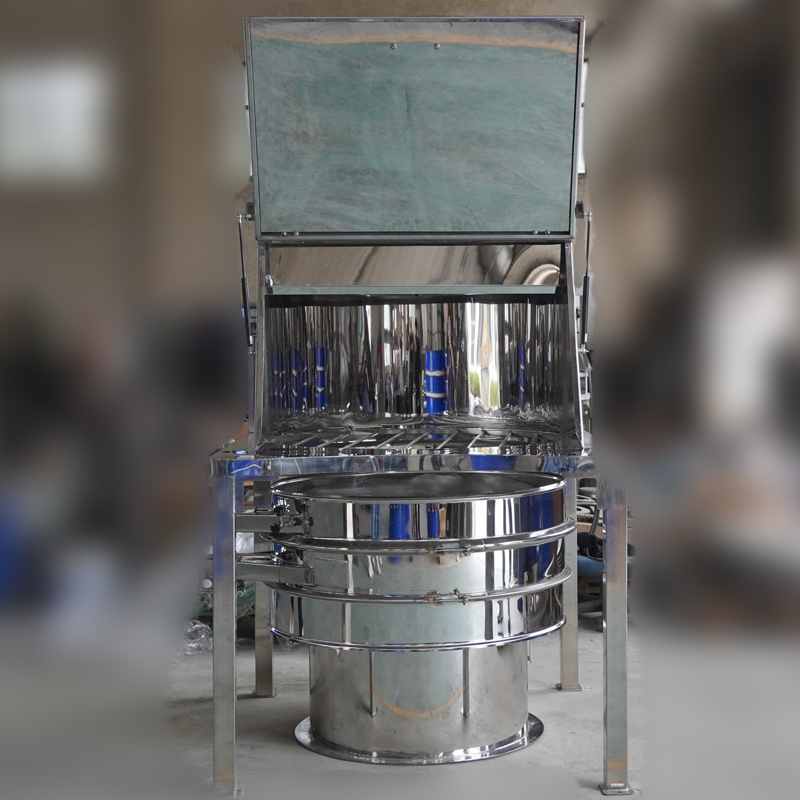

Dust-free feeding station

Dust-free feeding station is suitable for unpacking, placing, screening and discharging small bags of materials in pharmaceutical, chemical, food, battery materials and other industries. During unpacking, due to the function of dust collecting fan, the dust of materials can be prevented from flying everywhere. When the material is unpacked and poured into the next process, it only needs to be unpacked manually and put into the system directly. The material passes through the vibrating screen (safety screen), which can intercept large pieces of material and foreign matters, thus ensuring the discharge of particles that meet the requirements.

Direct discharge Features

Product show

Product Paramenters

|

Model

|

Speed

(rpm)

|

Air pressure

(Pa)

|

Air flow

(m³/h)

|

Sieving area

(m³)

|

We can customize according to customer's requirement

|

|

SYT-800

|

1460

|

1217-1641

|

1550-997

|

0.42

|

Can customize according to customer's requirement

|

|

SYT-1000

|

1460

|

|

|

0.64

|

|

Application Field

Hot Searches