- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Grandee

-

Dimension(L*W*H):

-

2.6*2.15*2.5m

-

Weight:

-

4000 KG

-

Product name:

-

Automatic Can Filling Seaming Machine

-

Can volume:

-

200ml-1000ml

-

Can diameter:

-

50-70mm

-

Can height:

-

1201-70mm

-

Filling speed:

-

4000-5000CPH

-

Usage:

-

Beverage Filling Packaging

-

Suitable for:

-

Carbonated Drink, Beer, Juice

-

Feature:

-

High Precision Filling Level

-

Control:

-

PLC+ Touch Screen

-

Processing:

-

Filling and Seaming

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Plastic, Metal

-

Filling Material:

-

Beer, Juice

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Grandee

-

Dimension(L*W*H):

-

2.6*2.15*2.5m

-

Weight:

-

4000 KG

-

Product name:

-

Automatic Can Filling Seaming Machine

-

Can volume:

-

200ml-1000ml

-

Can diameter:

-

50-70mm

-

Can height:

-

1201-70mm

-

Filling speed:

-

4000-5000CPH

-

Usage:

-

Beverage Filling Packaging

-

Suitable for:

-

Carbonated Drink, Beer, Juice

-

Feature:

-

High Precision Filling Level

-

Control:

-

PLC+ Touch Screen

-

Processing:

-

Filling and Seaming

GRANDEE MACHINE

is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development,engineering design, consulting, technical services and other integrated EPC solutions.

Products Description

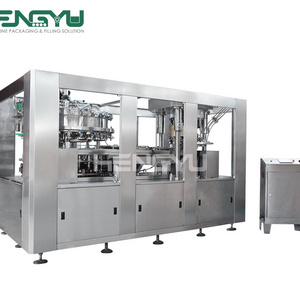

Carbonated Beer Can Filling Sealing Machine DGF12-1

Beer canning machine / soda water filling sealing machine for equal pressure can filling sealing machine of carbonated drinks in beer and drink industry. It is a pop canned beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. Filling and sealing is the overall designed, power system by filling sealing system to ensure that both the absolute synchronization and coordination. It adopts the advanced machine, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip long-distance control system according to the customers’ request. It is the preferred equipment for the medium beer and beverage plant.Auto depalletizer →Automatic can rinsing machine→Automatic soda water can filling machine→

Automatic can sealing machine→Can warmer(optional)→Blow dryer→Automatic or Manual sleeve labeling machine→Bottle Collection Table

Automatic can sealing machine→Can warmer(optional)→Blow dryer→Automatic or Manual sleeve labeling machine→Bottle Collection Table

Filling part

Adopt PLC, frequency converter and man-machine interface control system. It has advanced control technologies such as variable frequency speed regulation, automatic filling with cans, no filling without cans, etc. Through various sensors on the device, the accurate production speed and production quantity can be displayed on set it on the touch screen.

Sealing part

The finished cans are sent to the sealing machine head via a hook chain, and the lid is sent to the mouth of the tank through the

cap feeder. When the can supporting mechanism is raised, the indenter presses the mouth of the can, and the sealing wheel is

pre-sealed and sealed. After the can is sealed, it is pushed out by the canning mechanism to complete the process of filling and

sealing

cap feeder. When the can supporting mechanism is raised, the indenter presses the mouth of the can, and the sealing wheel is

pre-sealed and sealed. After the can is sealed, it is pushed out by the canning mechanism to complete the process of filling and

sealing

Main technical parameter

|

Model

|

GDF12-1

|

GDF12-4

|

GDF18-4

|

GDF24-4

|

GDF36-6

|

||||

|

Capacity (500ml)

|

1500-2000

|

2000-3000

|

4000-10000

|

8000-9000

|

10000-12000

|

||||

|

Filling type

|

Isobaric filling

|

|

|

|

|

||||

|

Filling pressure

|

<0.4MPa

|

|

|

|

|

||||

|

Rinsing water pressure

|

>0.06MPa <0.2MPa

|

|

|

|

|

||||

|

Application

|

Carbonated soft drink bottling line

|

|

|

|

|

||||

|

Total power

|

2.5kw

|

3.7kw

|

5.5kw

|

7.5kw

|

8.2kw

|

||||

|

Overall dimensions

|

2.5*1.9m

|

2.8*1.9m

|

2.5*2.2m

|

2.8*2.5m

|

3.6*2.3m

|

||||

|

Height

|

2.3m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

||||

|

Weight(KG)

|

2000

|

2500

|

3000

|

4500

|

6000

|

||||

For more information, please feel free to contact us to

send an inquiry!

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

MOTOR

|

ABB

|

SWISS

|

|

PNEUMATIC PARTS

|

FESTO

|

GERMANY

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

For more information, please feel free to contact us to

send an inquiry

!

Turnkey Solution

Hot Searches