- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

18kw, 36kw

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

500 mm *800mm

-

Name:

-

sterilization machine

-

Application:

-

High Temperature Sterilization Retort

-

Function:

-

High Temperature High Pressure Sterilizing

-

Material:

-

304 Stainless Steel sterilization machine

-

Sterilizing way:

-

Hot Water Spraying

-

Capacity:

-

50-1100kg

-

Feature:

-

Low Energy High Efficiency

-

Sterilizing Type:

-

Hot Water Sparying

-

MOQ:

-

1 Set sterilization machine

-

Usage:

-

Food Industry Equipment

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNOC

-

Voltage:

-

220V/380V

-

Power:

-

18kw, 36kw

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

500 mm *800mm

-

Name:

-

sterilization machine

-

Application:

-

High Temperature Sterilization Retort

-

Function:

-

High Temperature High Pressure Sterilizing

-

Material:

-

304 Stainless Steel sterilization machine

-

Sterilizing way:

-

Hot Water Spraying

-

Capacity:

-

50-1100kg

-

Feature:

-

Low Energy High Efficiency

-

Sterilizing Type:

-

Hot Water Sparying

-

MOQ:

-

1 Set sterilization machine

-

Usage:

-

Food Industry Equipment

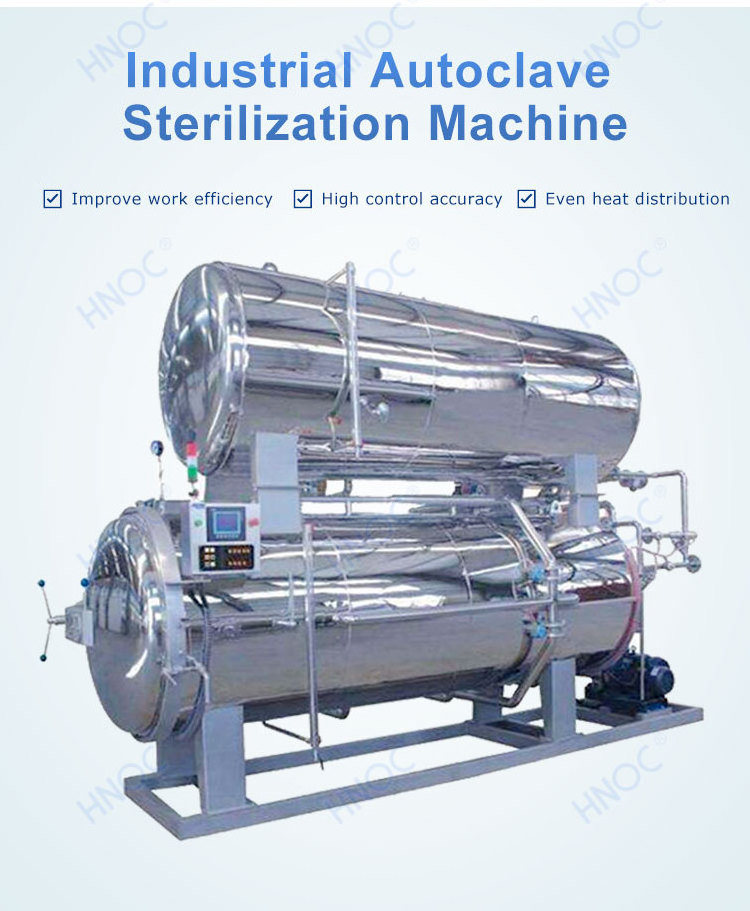

Cook Retort Autoclave Electric Steam Drink Canner Glass Sterilize Jar High Pressure Retort for Jarred Food

Product Description

Specification

|

Machine

|

Parameter

|

|

|

||

|

Sterilization tank(below) Inner diameter*length

|

500 mm *800mm

|

700 mm*1200mm

|

900 mm*1800mm

|

||

|

Hot water tank (top)Inner diameter*length

|

500 mm*800mm

|

700 mm*1200mm

|

900 mm*1800mm

|

||

|

Design Pressure(Mpa)

|

0.35

|

0.44

|

0.44

|

||

|

Max Working Pressure(Mpa)

|

0.30

|

0.44

|

0.44

|

||

|

Max Working Temperature

|

145℃

|

|

|

||

|

Electric heating power

|

18kw*2

|

36kw*2

|

36kw*2

|

||

|

Sterilization tray

|

3pcs

|

3pcs

|

3-4pcs

|

||

|

Sterilization car

|

1

|

1

|

2

|

||

|

Voltage

|

380V

|

|

|

||

|

Material

|

SUS304

|

|

|

||

1. Adopting the Technology of "precise Back Pressure Control in the Pot" and the Method of "wave-shaped Hot Water Injection", the Products in the Pot Can Be Fully and Evenly Pressed and Heated.

2. Adopt the "real-time Flow Accurate Measurement" Device. Ensure That the Product in the Pot is Evenly Heated to Avoid "cold Spots".

3. the Sterilizer is Equipped with Plc Intelligent Control and Fully Automatic Touch Screen, Which is Easy to Operate.

4. Before Leaving the Factory, the Sterilization Pot is Strictly Measured for Heat Distribution, and the Temperature Error is Strictly Controlled within 0.5 ℃.

5. the Cooling Water is Separated from the Sterilizing Water. It Will Not Cause Secondary Pollution, and at the Same Time It Can Be Recycled and Save Water.

6. the Sterilization Pot is Heated and Sterilized in a Short Time, the Flavor and Taste of the Produced Food Are Almost Unchanged, and the Range of Processed Products is Also Wider.

Direct Heating, Indirect Cooling. Improve Sterilization Efficiency.

Avoid Secondary Contamination of Food.

Direct Heating, Indirect Cooling

Reduce the Frequency of Use of Heat Exchangers,

Reduce Maintenance Times and Save Maintenance Costs.

◆Product Details:

Displays the Volume of Water in the Pot

The Material Cart is Used to Place the Product, and the Trolley is Used to Transport the Product, Which is Matched with the Equipment

Factory Real Shot

Related Products

Hot Searches