- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.2 - 2.5 mm

-

Heating Power (kW):

-

40 kW, 40

-

Air Comsumption(L/min):

-

2000 L/min

-

Water Comsumption(L/min):

-

4.8 L/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YIHAO

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

L7500*W2000*H2000 mm

-

Weight (T):

-

3 T

-

Power(KW):

-

120

-

Product Name:

-

Corn starch takeaway fast food machine

-

Finished Products:

-

Lunch Food Box, Tableware Plate

-

Raw Material:

-

Pulp Board made by Reeds, straw, bagasse, bamboo ect.

-

Certification:

-

CE

-

After-sales Service Provided:

-

Video technical support, Online Support

-

Capacity:

-

700~800kg/day

-

Sheet Thickness(mm)::

-

0.2 - 2.5 mm

-

Water Consumption:

-

0.01 L/min

-

Twin Screw Max Speed::

-

550r/min

Quick Details

-

Max.Forming Height(mm):

-

80 mm

-

Forming Width (mm):

-

780 mm

-

Forming Length (mm):

-

300 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.2 - 2.5 mm

-

Heating Power (kW):

-

40 kW, 40

-

Air Comsumption(L/min):

-

2000 L/min

-

Water Comsumption(L/min):

-

4.8 L/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YIHAO

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

L7500*W2000*H2000 mm

-

Weight (T):

-

3 T

-

Power(KW):

-

120

-

Product Name:

-

Corn starch takeaway fast food machine

-

Finished Products:

-

Lunch Food Box, Tableware Plate

-

Raw Material:

-

Pulp Board made by Reeds, straw, bagasse, bamboo ect.

-

Certification:

-

CE

-

After-sales Service Provided:

-

Video technical support, Online Support

-

Capacity:

-

700~800kg/day

-

Sheet Thickness(mm)::

-

0.2 - 2.5 mm

-

Water Consumption:

-

0.01 L/min

-

Twin Screw Max Speed::

-

550r/min

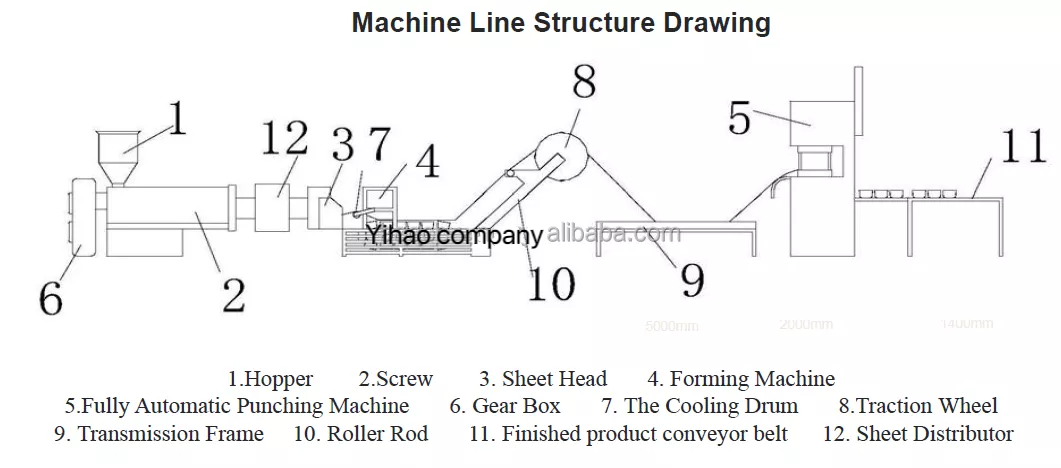

Machinery Introduction

Machine Advantages

1.Low Machinery Investment: Each line comes with all associate equipment that clients need to produce products: sheet extruding

machine, forming machine, fully automatic hydraulic punching machine, mixer, smash machine, one set of customized mold and punching knife.

2.Low Energy Consumption: The sheet extruding machine produces sheet directly to product forming and punching.No secondary heating

requires.

3.Adapt Multi Material: ps, pp with calcium, rice husk, bamboo, talcium, starch, straw, bamboo and other plant fiber.

4.Adapt Plastic Free Material: PLA, PBAT etc

5.Multi Application: By changing mold, the machine line is able to produce lunch box, food container, clamshell box, market tray,

food tray, bowl, plate etc. All mold can be customized according to clients needs.

6.High Automation and Easy Operation: Two workers are able to operate the full line each shift. One worker for packing and one for side material re-usage.

7.No material wastage: Side material can be smashed and re-mixed to be used again. There is no material wastage, no gas pollution and no water pollution during production process.

8.Durable and Reliable: The machine line is able to be running 24/7 without problem. Only Require basic maintenance.

1.Low Machinery Investment: Each line comes with all associate equipment that clients need to produce products: sheet extruding

machine, forming machine, fully automatic hydraulic punching machine, mixer, smash machine, one set of customized mold and punching knife.

2.Low Energy Consumption: The sheet extruding machine produces sheet directly to product forming and punching.No secondary heating

requires.

3.Adapt Multi Material: ps, pp with calcium, rice husk, bamboo, talcium, starch, straw, bamboo and other plant fiber.

4.Adapt Plastic Free Material: PLA, PBAT etc

5.Multi Application: By changing mold, the machine line is able to produce lunch box, food container, clamshell box, market tray,

food tray, bowl, plate etc. All mold can be customized according to clients needs.

6.High Automation and Easy Operation: Two workers are able to operate the full line each shift. One worker for packing and one for side material re-usage.

7.No material wastage: Side material can be smashed and re-mixed to be used again. There is no material wastage, no gas pollution and no water pollution during production process.

8.Durable and Reliable: The machine line is able to be running 24/7 without problem. Only Require basic maintenance.

Products Description

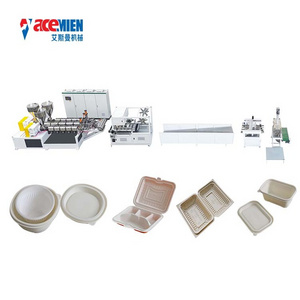

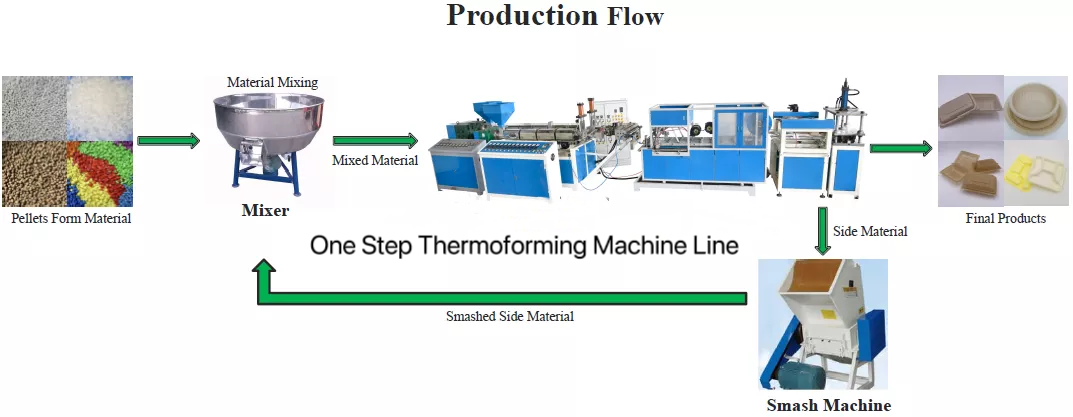

Disposable biodegradable plastic corn starch tableware lunch box food container tray plates making machine production line

The whole line includes three sets of machine:

1.PLA, PP, Corn Starch, talcum powder mixing machine

2.Granule machine

3.One-step tableware forming machine

1.PLA, PP, Corn Starch, talcum powder mixing machine

The mixing machine is used to mix PLA, polypropylene release agent, pp, straw granule and talcum powder with certain proportion,

after these raw material mixed each other, they will be make granule through granulator.

Disposable biodegradable plastic corn starch tableware lunch box food container tray plates making machine production line

The whole line includes three sets of machine:

1.PLA, PP, Corn Starch, talcum powder mixing machine

2.Granule machine

3.One-step tableware forming machine

1.PLA, PP, Corn Starch, talcum powder mixing machine

The mixing machine is used to mix PLA, polypropylene release agent, pp, straw granule and talcum powder with certain proportion,

after these raw material mixed each other, they will be make granule through granulator.

2. Twin-screw extruder Air-cooled pelletizing Machine Line

it is mainly used to extrude the finished-mixing material which will be heated and melted in the barrel, and the melted material is cooled into strip with fan, the cutter will cut these strips into granules.

it is mainly used to extrude the finished-mixing material which will be heated and melted in the barrel, and the melted material is cooled into strip with fan, the cutter will cut these strips into granules.

|

Item

|

Value

|

|

Group capacity

|

200-400kg / h

|

|

Twin-screw Nominal Diameter

|

62.4mm

|

|

Twin-screw host driving power

|

55KW

|

|

Twin Screw Max Speed

|

550r/min

|

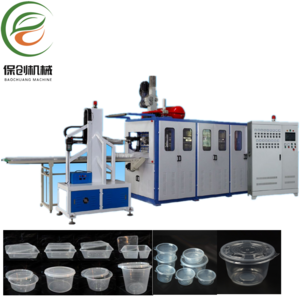

One-step tableware forming machine

One-step tableware forming machine will make the finished granules form tableware through heating, This machine is the latest core product developed by our company, integrated, punching, cutting, and stacking. It has a wide range of uses and is suitable for most customers' requirements. It can produce bowls, plates, various fast food boxes, packing boxes, supermarket trays, moon cake boxes, tofu boxes, biscuit boxes, etc. Stable operation, low noise, high efficiency and good quality.

One-step tableware forming machine will make the finished granules form tableware through heating, This machine is the latest core product developed by our company, integrated, punching, cutting, and stacking. It has a wide range of uses and is suitable for most customers' requirements. It can produce bowls, plates, various fast food boxes, packing boxes, supermarket trays, moon cake boxes, tofu boxes, biscuit boxes, etc. Stable operation, low noise, high efficiency and good quality.

Processing Raw Material Available

Biodegradable PBAT

Talcum Master Batch

Grain Filber

Color Master

Calcium Carbonate

Wheat Straw

Bombo Filber

PLA

Bagasse

|

90B Sheet Extruder

|

|

|

|

Length-To-Diametre Ratio Of Screw

|

1:33

|

|

|

Screw Size

|

90mm

|

|

|

Screw Rotation Speed

|

10~80r/min

|

|

|

Extrusion Output

|

130-180kg/h

|

|

|

Power of Main Motor

|

37KW

|

|

|

Sheet Extruding Head Size

|

1000mm

|

|

|

Forming Machine

|

|

|

|

Maximum Shaping Area

|

850mm×300mm

|

|

|

Maximum Shaping Depth

|

80mm

|

|

|

Cooling Method

|

Fan Cooling

|

|

|

Output Capacity

|

20-45 mold/min

|

|

|

Controller

|

PLC

|

|

|

Power of Shaping Section

|

1.5kw

|

|

|

Fully Automatic Punching Machine

|

|

|

|

Controller

|

PLC

|

|

|

Servo Motor

|

Two

|

|

|

Mode

|

Hydralic

|

|

|

Punching Speed

|

20-50 time/min

|

|

|

Product Counting

|

Yes

|

|

|

Maximum Punching Area

|

1000mm*350mm

|

|

Fully Automatic Cam Punching Machine

1. Saving labor: Auto product counting, stacking, conveying.

2. Faster punching speed: maximum punching speed reaches 55 times per minute.

3. Lower punching noise.

3. Lower punching noise.

Customized Mold

1. Maximum mold install area reaches 850mm*350mm.2. All mold are customized, client choose to add logo, words and signs on mold.

3.Each Line comes with one set of free customized mold.

3.Each Line comes with one set of free customized mold.

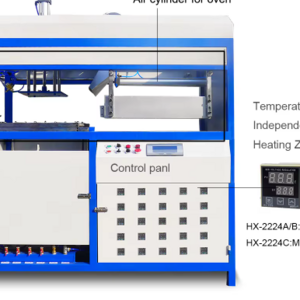

PLC control Forming Machine

By changing mold, machine produces different size and type clamshell box, food box, lunch container, bowl, plate, meal tray market tray etc.

Multi Layer Sheet Distributor

The Triple screw sheet extruder produces maximum four layers ABCA sheet:products with two colors and surface coating.

Application

Calcium Carbonate Products

Contact us :

Person : Jennifer

whatsapp/wechat :+8615615355370

Email : rachel@yihaomachine.com.cn

Hot Searches