- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Dakiou

-

Voltage:

-

380V, 380V

-

Dimension(L*W*H):

-

10000 x 4000 x 2000 mm, 10000 x 4000 x 2000 mm

-

Weight:

-

13T, 13T

-

Product name:

-

Full-stripping Roll Die Cutting and Creasing Machine

-

Certification:

-

CE, CE

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

90-150times/min

-

Max. workable width:

-

950 x540mm Or 950 x640mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Dakiou

-

Voltage:

-

380V, 380V

-

Dimension(L*W*H):

-

10000 x 4000 x 2000 mm, 10000 x 4000 x 2000 mm

-

Weight:

-

13T, 13T

-

Product name:

-

Full-stripping Roll Die Cutting and Creasing Machine

-

Certification:

-

CE, CE

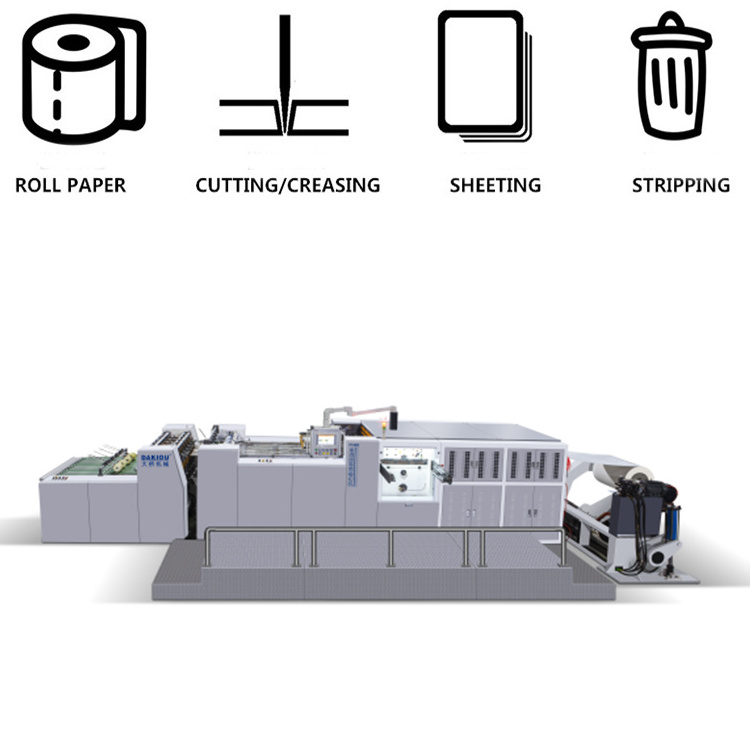

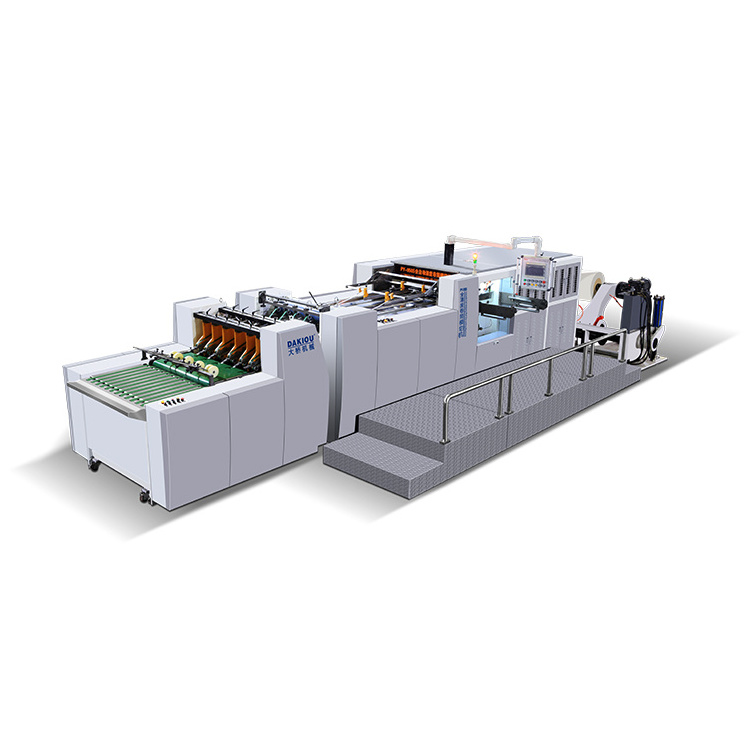

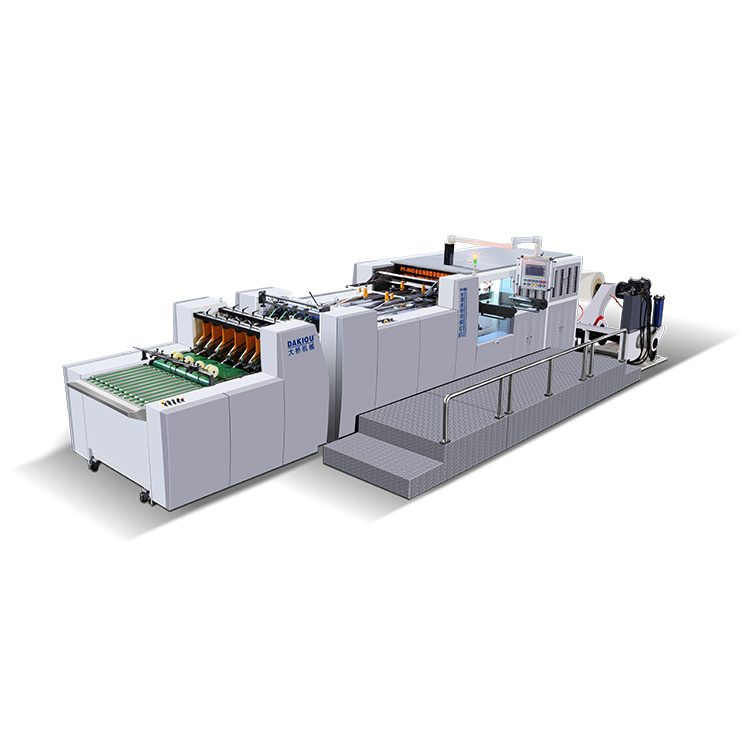

PY Automatic Full-stripping Roll Die Cutting Machine can complete full steps from roll to finished product including die cutting, creasing, stripping and collection. It is an ideal equipment for producing paper cups fan, paper boxes, cards etc of post-press packaging.

Easy and safety operation, High efficiency.

Technical Specification:

|

Type: |

PY-950S |

|

Cut Precision: |

± 0.10mm |

|

Capacity |

90-150 times/min |

|

Max cutting size: |

950 x540mm Or 950 x640mm |

|

Max feeding Width: |

950mm |

|

Suitable Material: |

120-600g/m2 P e coated paper, cardboard paper, K raft paper etc |

|

Maximum Pressure: |

350T |

|

Total Power: |

30KW |

|

Weight: |

12T |

|

Overall Dimension: |

10000 x 4000 x 2000 mm |

|

Working Air Source: |

Air pressure 0.5-0.7Mpa |

Main Feature:

1.The normal working,speed is 90-120times per minute. It has the ability to die-cutting, creasing, sheeting, stripping and collecting.

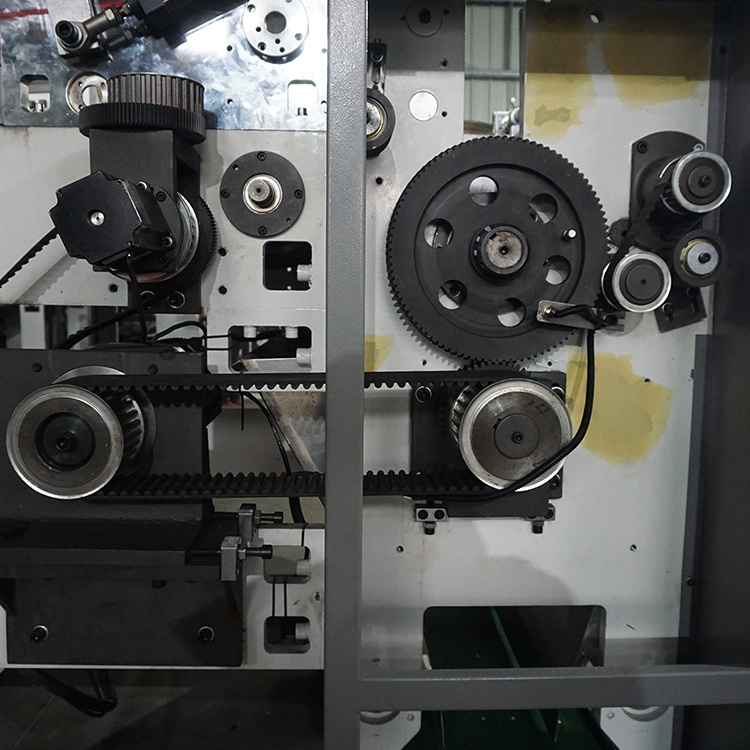

2.Imported servo motor driving, imported color sensor recognizition, new sheeting design(the old type use the rod flapping to sheeting) ,full-stripping by pinheads, automatic stack collecting.

3.Worm wheel and worm transmission system ensures the powerful and steady pressure. Lubricating with oil circulation and alarming when lack of oil.

4.Equipped shaftless unwinding unit, and use the pneumatic brake and multilevel tension controller to control roll paper unwinding.

5.Use PLC as its control center, in coordination with original LG electrical elements from KOREA, original Panasonic sensor from JAPAN, original SHAKO and MINGMAN pneumatic parts.

6.Alarming system: lubrication blocking alarming, paper feeding blocking alarming, limit alarming, stripping failed alarming.

7.The main body is much stronger. We use the more thick steel board and cast iron board instead of the normal one.