- Product Details

- {{item.text}}

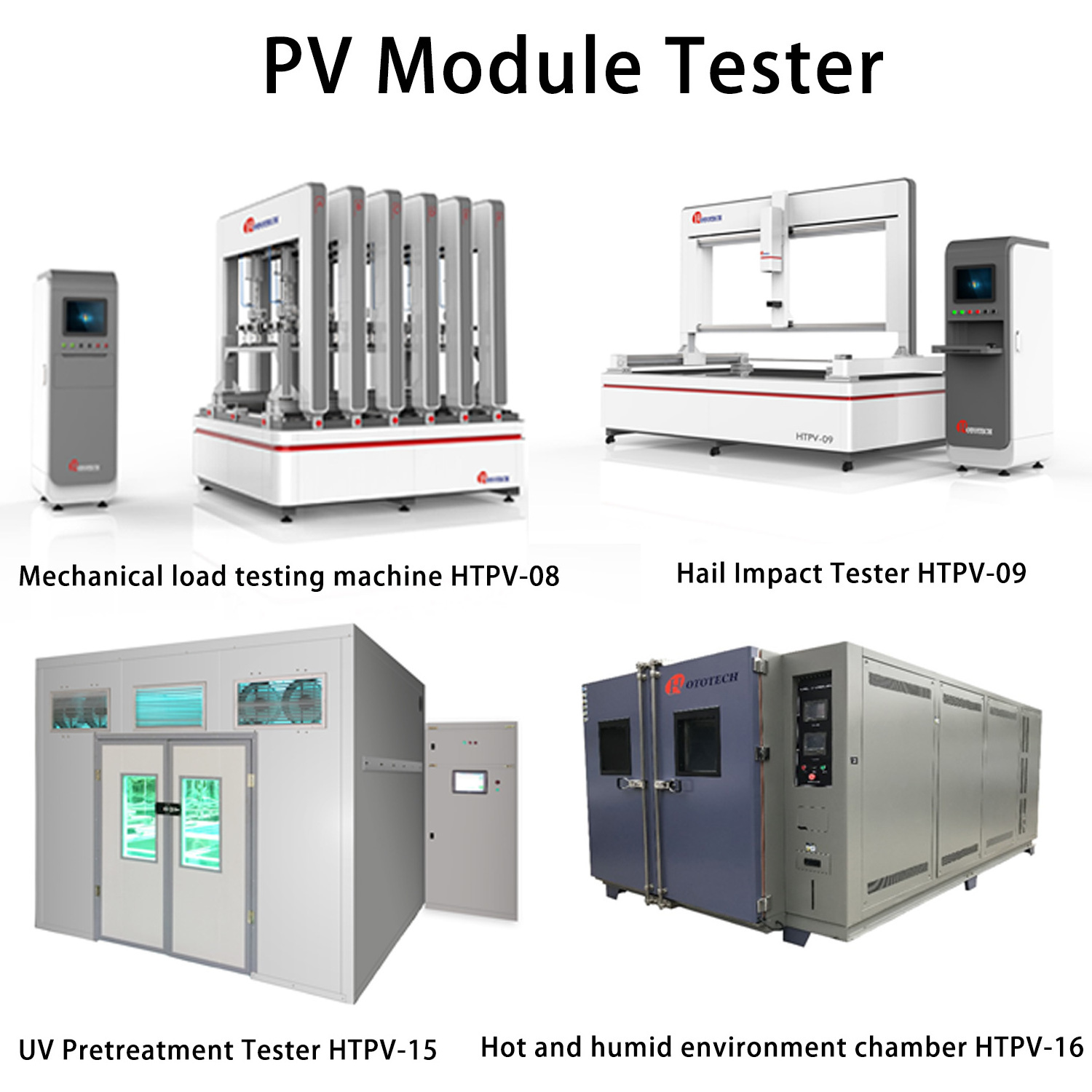

Quick Details

-

Model Number:

-

HTPV-08

-

Test Positive load:

-

5400Pa

-

reverse load:

-

2400Pa

-

The machine table appearance dimension:

-

L 280 * D 180 * H 195 cm

-

Cycle times:

-

Free to set

-

Dynamic laod test frequency:

-

7s

-

Test standard:

-

IEC61215-2:2016

-

Applilcation:

-

Solar panel

-

Control ways:

-

Computer control

-

Cylinder:

-

8 (can customized)

-

Power supply:

-

280V 50Hz

Quick Details

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Hototech

-

Model Number:

-

HTPV-08

-

Test Positive load:

-

5400Pa

-

reverse load:

-

2400Pa

-

The machine table appearance dimension:

-

L 280 * D 180 * H 195 cm

-

Cycle times:

-

Free to set

-

Dynamic laod test frequency:

-

7s

-

Test standard:

-

IEC61215-2:2016

-

Applilcation:

-

Solar panel

-

Control ways:

-

Computer control

-

Cylinder:

-

8 (can customized)

-

Power supply:

-

280V 50Hz

Manufacturing Technique

Specification

|

item

|

value

|

|

Customized support

|

OEM

|

|

Place of Origin

|

China

|

|

|

Guangdong

|

|

Brand Name

|

Hototech

|

|

Model Number

|

HTPV-08

|

|

Power

|

Electronic

|

|

Test Positive load

|

5400Pa

|

|

reverse load

|

2400Pa

|

|

The machine table appearance dimension

|

L 280 * D 180 * H 195 cm

|

|

Cycle times

|

Free to set

|

|

Dynamic laod test frequency

|

7s

|

|

Test standard

|

IEC61215-2:2016

|

|

Applilcation

|

Solar panel

|

|

Control ways

|

Computer control

|

|

Cylinder

|

8 (can customized)

|

|

Power supply

|

280V 50Hz

|

Standard

According to IEC 61215, UL1703, IEC62782 standard requirement

Purpose

This test is to determine the ability of the module to withstand wind , snow , static or ice loads

Technical specifications

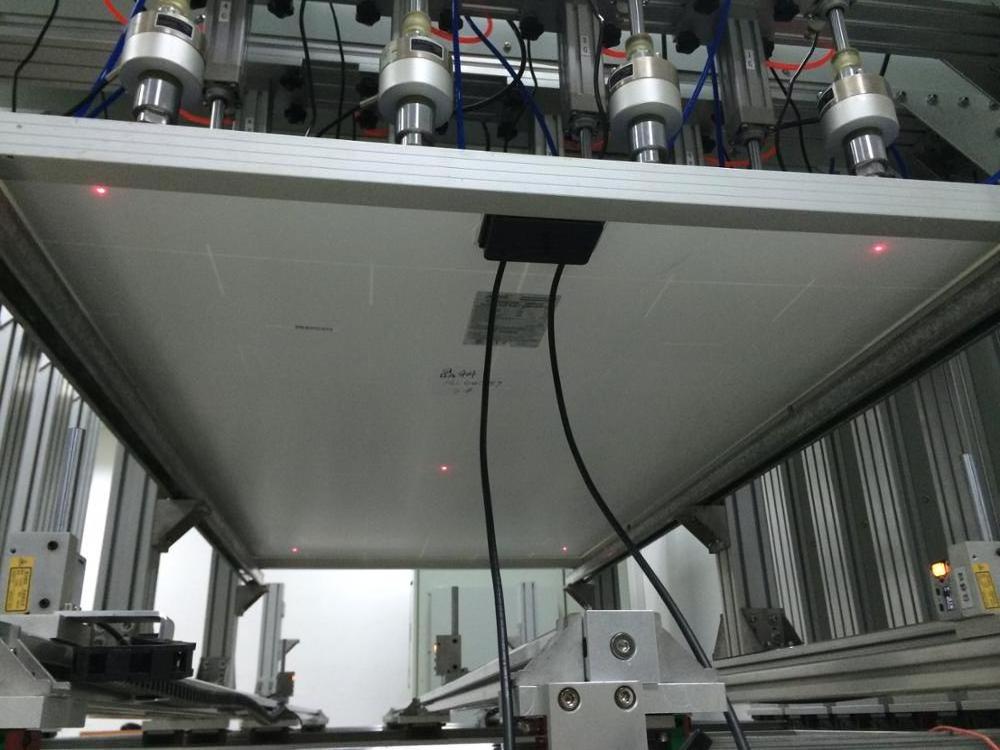

1,The machine table appearance dimension:L 280 × D 180 × H 195 cm

2,Test Positive load 5400Pa, reverse load :2400Pa (Pressure can setting)

3,Cycle times :free setting

4,Dynamic load test frequency:7s±3s

5,Dynamic load:1000Pa,1000tims

6,Pressure control accurate:5%

7,Pneumatic and force value feedback ways :low friction force cylinder,tensile pressure

sensor(accurate 0.1N)

8,Aluminum profile structure feature:platform and support frame aren’t deformation under the suffer force situation

9,The maximum test dimension:2000mm×1000mm (can according to customer’s requirement to customized)

10,Customization test platform fixture, according to determinand install ways to do the adjust

11,Current continuity system :DC power, DC 150V/2A, real-time monitor module inner current continuity

12,Cylinder: 4 groups , in total 8 pieces

Single the maximum output > 200 kg

Telescopic stroke:125mm

13,Sucker:8 groups , in total 32 pieces

Sucker diameter:120mm

Sucker(with cylinder) space horizontal and vertical≤200mm

Sucker can rotation angle ≥15°

14,Operate system

14.1,Computer control software research and development by HOTOTECH , easy operate and stability

14.2,Software with Chinese and English language , can change each other

14.3,real-time show pressure, deformation, test time, cycle times , current continuity

14.4,Real-time draw and show pressure and deformation value

14.5,Real-time show every cylinder force value and draw force value curve

14.6,Testing data real-time save, inquiry and print

14.7,Testing data export is World, Excel, PDF , JPG etc format

14.8,Fault alarm function

According to IEC 61215, UL1703, IEC62782 standard requirement

Purpose

This test is to determine the ability of the module to withstand wind , snow , static or ice loads

Technical specifications

1,The machine table appearance dimension:L 280 × D 180 × H 195 cm

2,Test Positive load 5400Pa, reverse load :2400Pa (Pressure can setting)

3,Cycle times :free setting

4,Dynamic load test frequency:7s±3s

5,Dynamic load:1000Pa,1000tims

6,Pressure control accurate:5%

7,Pneumatic and force value feedback ways :low friction force cylinder,tensile pressure

sensor(accurate 0.1N)

8,Aluminum profile structure feature:platform and support frame aren’t deformation under the suffer force situation

9,The maximum test dimension:2000mm×1000mm (can according to customer’s requirement to customized)

10,Customization test platform fixture, according to determinand install ways to do the adjust

11,Current continuity system :DC power, DC 150V/2A, real-time monitor module inner current continuity

12,Cylinder: 4 groups , in total 8 pieces

Single the maximum output > 200 kg

Telescopic stroke:125mm

13,Sucker:8 groups , in total 32 pieces

Sucker diameter:120mm

Sucker(with cylinder) space horizontal and vertical≤200mm

Sucker can rotation angle ≥15°

14,Operate system

14.1,Computer control software research and development by HOTOTECH , easy operate and stability

14.2,Software with Chinese and English language , can change each other

14.3,real-time show pressure, deformation, test time, cycle times , current continuity

14.4,Real-time draw and show pressure and deformation value

14.5,Real-time show every cylinder force value and draw force value curve

14.6,Testing data real-time save, inquiry and print

14.7,Testing data export is World, Excel, PDF , JPG etc format

14.8,Fault alarm function

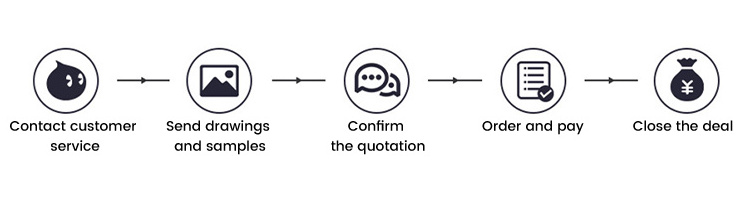

Product Description

Why Choose Us

Hot Searches