- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wangda Brand

-

Voltage:

-

usually 380V/50Hz 3phases

-

Dimension(L*W*H):

-

5500*3400*2100mm

-

Weight (KG):

-

10000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Body of brick making machine:

-

Whole steel

-

Decelerator of brick making machine:

-

equiped

-

Processlng materlals:

-

clay, shale, coal gangue, fly ash, slag, mountain mud, silt, etc

-

Moisture content of green bricks:

-

16-18%

-

Reamer diameter(mm):

-

450mm

-

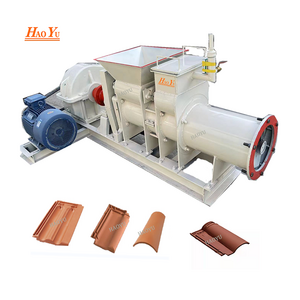

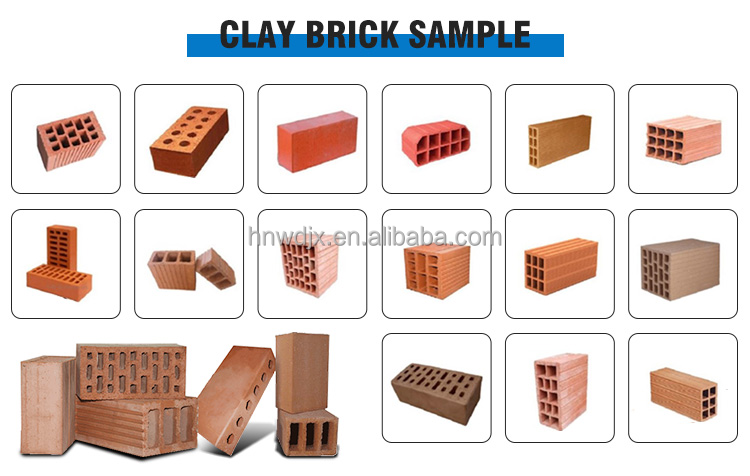

Final bricks:

-

solid, hollow clay brick

-

kiln kind of brick making machine:

-

tunnel kiln or hoffman kiln

-

Consumption of brick making machine:

-

lowest

-

Certification:

-

CE, CA,CCC,CQC,GB/T,ISO9001:2008

Quick Details

-

Type:

-

Hollow Block Making Machine, Vacuum Extruder Clay Brick Machine

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

11000-13000 pcs/hour

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wangda Brand

-

Voltage:

-

usually 380V/50Hz 3phases

-

Dimension(L*W*H):

-

5500*3400*2100mm

-

Weight (KG):

-

10000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Body of brick making machine:

-

Whole steel

-

Decelerator of brick making machine:

-

equiped

-

Processlng materlals:

-

clay, shale, coal gangue, fly ash, slag, mountain mud, silt, etc

-

Moisture content of green bricks:

-

16-18%

-

Reamer diameter(mm):

-

450mm

-

Final bricks:

-

solid, hollow clay brick

-

kiln kind of brick making machine:

-

tunnel kiln or hoffman kiln

-

Consumption of brick making machine:

-

lowest

-

Certification:

-

CE, CA,CCC,CQC,GB/T,ISO9001:2008

Wangda brick making machinery factory

-- China professional brick making machine leader

Hot Latest clay extrusion baked soil brick making machine sintering brick production line

Easy operate! Labor saving! Best quality! High capacity!

Processing overview:

Vacuum extrusion production line equipments are mainly applied for raw materials like clay,silt,mud,shale,coal gangue,etc. when their particle sizes meet the requirements.

After the processing of aging,mixing,extrusion.strip cutting,blank cutting,setting,sintering,it can provide our clients the required environmental wall material brick types.

The key equipment automatic red soil brick making machine (Wangda JKY series hard plastic material vacuum brick making machine your best choice!)

Are there any differences among the brick making machines?

In the brick making machine market,there are three kinds extruders:

JKR(soft plastic material) vacuum extruder

JKB(Medium plastic material) vacuum extruder

JKY (Hard plastic material) vacuum extruder

Brief introduction of our automatic red soil brick making machine

"Wangda Brand" brick making machine is a new brick making equipment designed and manufactured by our factory through several researches absorbed the domestic and international advanced technology of developed countries like Germany,Italy,and the United States. JKY series hard plastic materials double stage vacuum extruder ,which allowable pressure could reach 4.0 Mpa. The forming moisture of the bricks is about 16%-18% so the bricks are easy to bake. It's the ideal equipment for production all kinds of bricks.

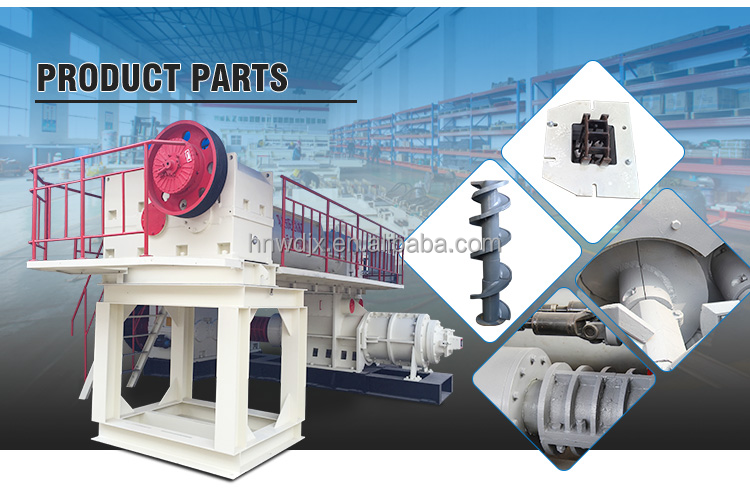

Special structures:

In the above picture:1. pneumatic clutch 2.clay press plate 3.cardan joint 4. clay press plate axis and main axis 5. hard herringbone tooth gear 6.speed reducer 7.vacuum chamber 8.half cylinder and brick mould

Main technical parameters of JKB45/45-3.0 Automatic Clay Brick Making Machine:

| S/N | Item | JKB45/45-3.0 Two Stage Vacuum Extruder Clay Brick Machine |

| 1 | Production Capacity | 11000-13000 pcs/hour |

| 2 | Extrusion Pressure | 3.0 |

| 3 | Vacuum Degree | ≥0.092 |

| 4 | Motor Power | 45kw * 110kw |

| 5 | Moisture Content | 16%-18% |

Which kilnd of kiln will your brick factory use?

Two kinds of kilns for your reference:tunnel kiln and hoffman kiln.

What's hoffman kiln?

Hoffman kiln is a traditional sintering process,twice setting then firing.Recommend Capacity:about 20,000-30,000pcs/day or under

Adavatages : Low investment,suitable for small capacity .

Disvantages : Large space occupied,low automation,operating conditions not well,high labor intensity.

How many kinds of machines will you need for your brick making production line?

(1). Raw materials handling equipments :Box feeder, roller crusher,double shaft mixer

(2). Ageing systerm equipments

(3). Green bricks making equipments :vacuum extruder( automatic clay brick roller kiln machine ),strip and blank cutting machine

(4). Brick setting machine (especially for tunnel kiln)

(5). Kiln equipments

Why we are the bricks factory invester's best choice?

We are a high-tech enterprise, integrating science, industry and trade for brick and tile machinery with our brand more than 30 varieties and over 100 specifications. Now we have built more than 2000 brick production line in China and abroad.

Our automatic red soil brick making machine are deeply trusted by customers ,have been sold in large amount to more than twenty provinces and municipalities and also export to India,Bangladesh ,Kazakhstan,Mongolia,Russia,North Korea,Vietnam,Burma,Iraq and other countries.

1.Q: What you could provide us?

A:Brick making machine's type chossing,plant design,kiln building,or turn-key project,and so on.

2.Q: How it works?

A:See the video:

3.Q: What's your minimum order?

A: 1 set brick making machine or other equipment.

4. Q: What's your gaurantee period?

A:12 months,after one year,we also provide wo also provide technical and other supports.

5.Q: What's your delivery time?

A: Prompt goods or 7-15 days after payment.

6.Q: Can you print our logo?

A:Yes, of course.If have this requirement just tell us is ok.

7.Q: What's your payment terms?

A: T/T ,L/C.

8.Q: Do you have plant for our visit?

A:Yes.Nowadys,our India customer's site about 100,000-200,000 pcs/day with tunnel kiln have came into smothly use.If you want visit,I could help you to arrange! Also welcome to visit the sites near our factory in China,many brick factries are using our whole automatic production line equipments many years!

9.Q: If visit your factory,how could we get there?

A:Fly to Xinzheng Airport,then we will pick up you.

10.Q: How to contact you?

A: Send Inquiry with details in the below, Click " Send " Now!

Any questions, pls feel free to contact me anytime.Looking forward to cooperating with you !

Whatsapp/Wechat:+86 15537175156

The same quality,we are lowest price!

The same price,we are highest configuration!

Wangda machinery factory sincerely waitting for your coming......