- Product Details

- {{item.text}}

Quick Details

-

Power:

-

9.4KW

-

Dimension(L*W*H):

-

3900mm*1100mm*2950mm

-

Weight (KG):

-

2000

-

Working space:

-

1200*1100*820mm

-

Inlet Width:

-

800-1500mm

-

Total Power:

-

9.4kw

-

Filters:

-

6Pieces

-

Clyclone Saparator:

-

1 SET

-

Blowing Gun:

-

1 SET

-

Automatic spray gun:

-

12 -24pieces

-

Air pressure:

-

8bar

-

Conveyor Belt:

-

4000mm length

-

Sand Size:

-

24-200mu

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Mingderixin

-

Marketing Type:

-

New Product 2024

-

Power:

-

9.4KW

-

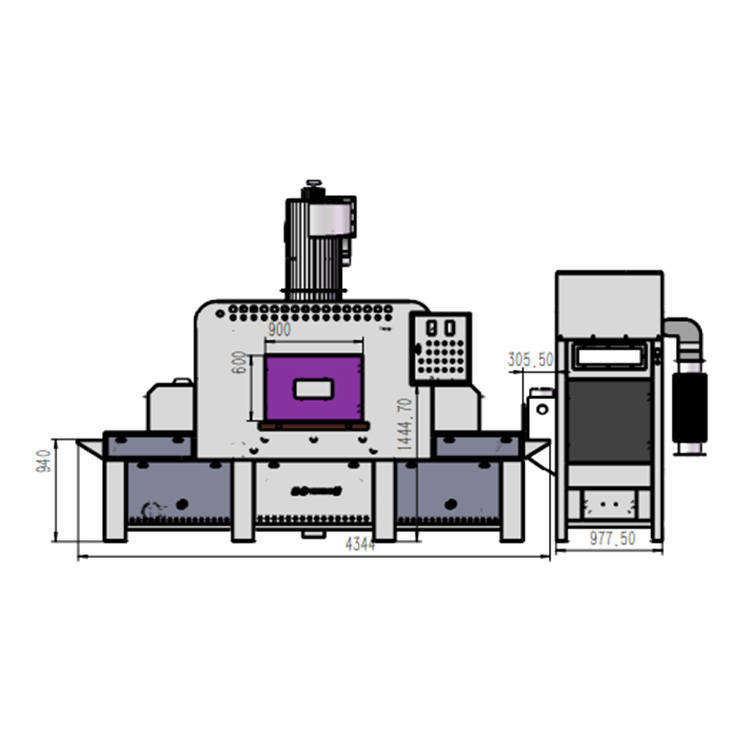

Dimension(L*W*H):

-

3900mm*1100mm*2950mm

-

Weight (KG):

-

2000

-

Working space:

-

1200*1100*820mm

-

Inlet Width:

-

800-1500mm

-

Total Power:

-

9.4kw

-

Filters:

-

6Pieces

-

Clyclone Saparator:

-

1 SET

-

Blowing Gun:

-

1 SET

-

Automatic spray gun:

-

12 -24pieces

-

Air pressure:

-

8bar

-

Conveyor Belt:

-

4000mm length

-

Sand Size:

-

24-200mu

Conveyor Belt Automatic Sand Blasting Machine /Sandblaster

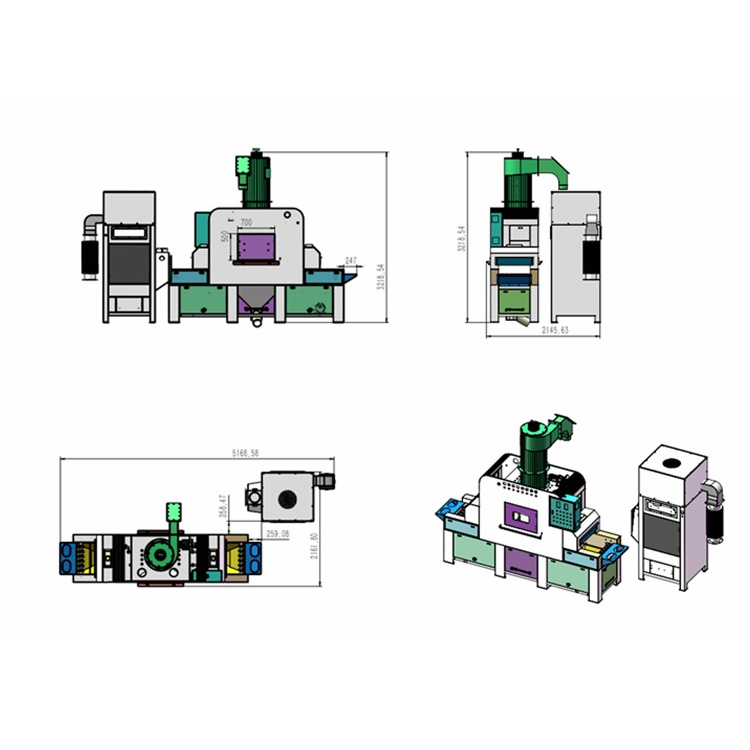

1-Specification

|

No. |

Components |

Specification |

|

1 |

Main Machine |

Material: 2.0mm Steel Board welded ,painted on the surface Shield and rubber skin are provided at the feeding and discharging ends Dust escapes, and a filter at the bottom of the cabin prevents large debris and workpieces from falling into the sand. Impact resistant surface in the cabin |

|

2 |

Overall Size |

3900mm(L)*1100mm(W)*2950mm(H) |

|

3 |

Spray Area |

1200mm(L)*1100mm(W)*820mm(H) |

|

4 |

Conveyor System |

The workpiece is conveyed by ductile iron pulley and C-belt. Motor power : 0.75kw. It can be steplessly regulated by the inverter in the range of 0~20m/min. |

|

5 |

Inlet Width |

900mm(W) |

|

6 |

Gun |

Total : 16 pieces 12 gun linkage swing mechanism + left and right 2 gun translation Swing Speed :15m/min Motor Power: 0.4kw Gun location and angle : adjustable Nozzle: 8mm Control : separately , 16 swinging guns Each gun is controlled by a separate pressure regulator and pressure gauge |

|

7 |

Blowing gun |

This machine is equipped with a set of small oil nozzles at the entrance and exit of the main machine for blowing the workpiece after sandblasting. |

|

8 |

Cyclone separator |

The first-stage cyclone separator consists of a separator, a sand trap, etc. 1) The first-stage cyclone separator is composed of an air volume adjusting plate, a core tube, a cylinder body and the like. a. The regulator body is welded with 2mm cold-rolled steel plate and painted on the surface. b. The core tube is welded by 2mm cold-rolled steel plate and painted on the surface. c. The cylinder is welded by 2mm cold-rolled steel plate and painted on the surface. 2), sand storage box: welded by 2mm high quality low carbon steel plate. Used to store sand and connect the spray gun sand tube. Inside Two 0.6KW heating units are installed to prevent the sand from being wet. 3) The secondary cyclone separator consists of a separator cylinder, a connecting pipe, and the like. Using a centrifugal force to place the primary separator After the fine sand and part of the dust flowing out from the outlet are collected again, some of the dust is left to the filter dust box. Filter to reduce dust pollution. Non-coated insulating coating inside the cyclone separator |

|

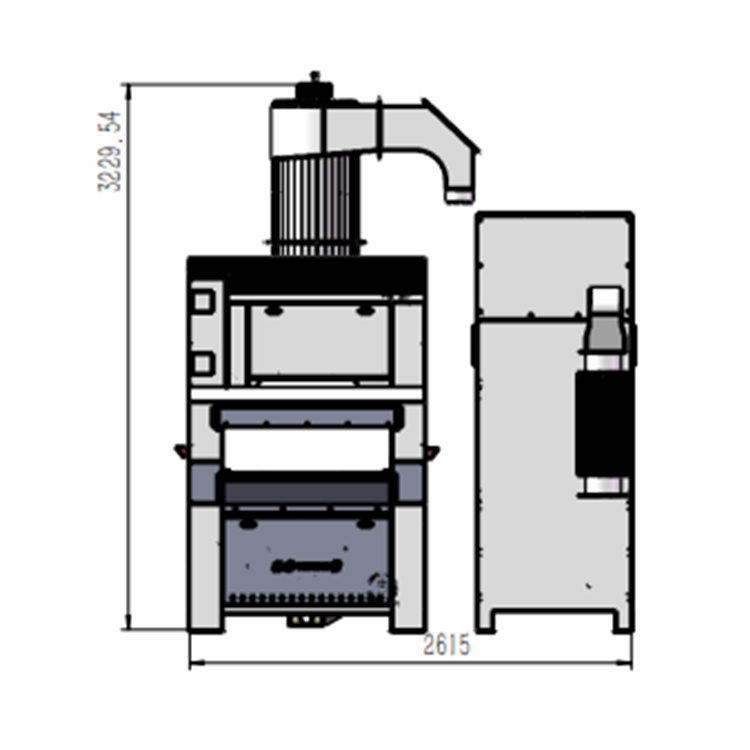

9 |

Dust Remove System |

Size:1300mmL*1000mmW*1910mmH Filters: 6pieces Size : 320*660mm Fan power: 7.5kw, rotated Speed :2900 |

|

10 |

Compressed Air |

Pressure : 1-7bar |

|

11 |

Consumption |

Centrifugal fan 1 set: 7.5kw ; Spray gun swing motor 1 set: 0.4kw; Conveying motor 1 set: 0.75kw ; Heating device 1 set: 1.0kw ; Lighting and control circuit: 0.25kw |

2- Feature

1. The operation is simple and the efficiency is high. The sand material can be replaced according to the process requirements, and the sand material is automatically recycled to save costs.

2. The workpiece conveying speed is steplessly regulated by the inverter according to the process parameters of the workpiece, achieving satisfactory sandblasting effect.

3, the number of spray guns 8-20, not only to meet the requirements of large-volume blasting production of products and to ensure the quality of sand blasting, colleagues can reduce the number of machine purchases and equipment occupied by the venue when re-determining the capacity, greatly saving the procurement cost of equipment

4, the spray gun only uses the angle swing mode and frequency conversion speed regulation, can manually fine-tune various spray angles, and has achieved good processing results.

5, the machine is equipped with two cyclones

It is an E-type cyclone separator, which can effectively separate swimming sand and dust, can recover the escaped sally and reduce the loss of sand. The E-type separator is mainly used for the separation of fine sand materials above 100#, and the bottom of the separator is baked. The dry device can dry the moisture in the sand material, keep the sand material dry, and avoid the spray gun duress caused by the sand supermarket. The second level is a funny cyclone separator, which will reduce the sand loss and reduce the burden of the filter cartridge.

6. Equipped with filter dust collector, it can clear the dust generated during work, and can avoid the phenomenon of dust spontaneous combustion.

7. All pipes and material pipes are made of smooth metal pipe or ESD material.

3- Advantage

4-Related Product

|

No. |

Models |

Belt Width (mm) |

Guns quantity |

|

1 |

MD-AS01 |

600mm |

8 |

|

2 |

MD-AS02 |

800mm |

12 |

|

3 |

MD-AS03 |

900mm |

16 |

|

4 |

MD-AS04 |

1000mm |

16 |

Factory