- Product Details

- {{item.text}}

Quick Details

-

Weight (T):

-

2 T

-

Power (kW):

-

45

-

Product Name:

-

ceramic shuttle kiln

-

Max Temperature:

-

2192F(1200 C)

-

Chamber size:

-

2500*1500*1500mm(Can Be Customized)

-

Heating element:

-

Resistance Belts

-

Chamber material:

-

Alumina Ceramic Fiber

-

Power:

-

450KW

-

Dimension:

-

4750*2980*2870

-

After-sales Service Provided:

-

Free spare parts

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dming

-

Voltage:

-

220V/380V, 380V

-

Weight (T):

-

2 T

-

Power (kW):

-

45

-

Product Name:

-

ceramic shuttle kiln

-

Max Temperature:

-

2192F(1200 C)

-

Chamber size:

-

2500*1500*1500mm(Can Be Customized)

-

Heating element:

-

Resistance Belts

-

Chamber material:

-

Alumina Ceramic Fiber

-

Power:

-

450KW

-

Dimension:

-

4750*2980*2870

-

After-sales Service Provided:

-

Free spare parts

drop bottom loading furnace ceramics oven shuttle gas furnace kiln shuttle furnace gas kiln

drop bottom loading furnace ceramics oven shuttle gas furnace kiln shuttle furnace gas kiln

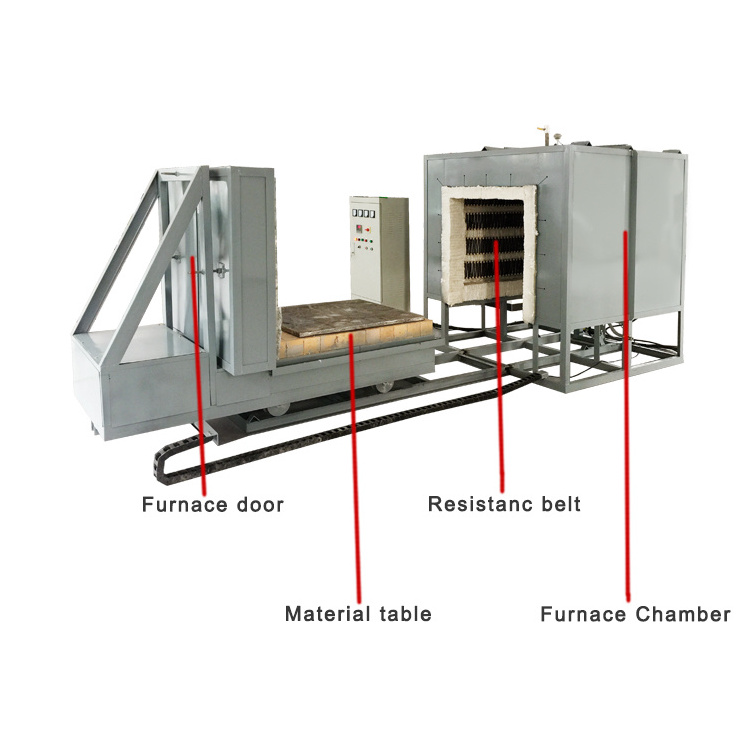

The design of ceramic shuttle furnace is divided into two types: medium temperature ( 0 ~ 950 ℃ ) and high temperature ( 0 ~ 1200 ℃ ) , which is mainly used for High chromium, high manganese steel castings, gray cast iron parts, ductile iron parts, rolls, steel balls, crusher hammers, wear-resistant linings quenching, annealing, aging and heat treatment of various mechanical parts .

Featur es:

l Maximum temperature 950 ℃ and 1200 ℃ .

l All-fiber ceramic l ining, high thermal efficiency, low heat loss and long lifetime.

l Four-side heating device achieves excellent temperature uniformity

l Japa nese ceramic nails, ensure the installation of heating elements with long life time .

l Build horizontal silicon carbide plate/high temperature cast steel plate for trolley.

l Intelligent program temperature control ler , which is available to edit and save multi-segment program.

Additional accessories:

l Electrical hydraulic lift furnace door

l Circulating hot air blower and thermal deflector

l Horizontal moveable a uxiliary trolley

l Automatically turn-able trolley easy for quenching

l Temperature control by different zone s to improve temperature uniformit y

l Visualized PLC automatic control system to monitor and record in real time

l Top exhaust valve, and inlet valves on both sides

1. Medium temperature trolley ( 0 ~ 950 ℃ )

|

Model |

Chamber size ( LWH ) mm |

Power ( KW ) |

Dimensions ( LWH ) mm |

|

D M -CBF-45 |

1100×550×450 |

45 |

3040×1480×1620 |

|

D M -CBF-50 |

1300×650×450 |

50 |

3240×1580×1620 |

|

DM -CBF-75 |

1500×700×600 |

75 |

3440×1630×1770 |

|

DM -CBF-90 |

1500×800×600 |

90 |

3440×1730×1770 |

|

DM -CBF-105 |

1800×900×700 |

105 |

3740×1830×1870 |

|

DM -CBF-135 |

2100×1050×750 |

135 |

4060×2010×1980 |

|

DM -CBF-150 |

2300×1200×650 |

150 |

4260×2560×1880 |

|

DM -CBF-300 |

2500×1500×1500 |

300 |

4690×2860×2750 |

2. High temperature trolley furnace ( 0 ~ 1200 ℃ )

|

Model |

Chamber size ( LWH ) mm |

Power ( KW ) |

Dimensions ( LWH ) mm |

|

DM -CBF-65 |

1100×550×450 |

65 |

3100×1600×1750 |

|

DM -CBF-75 |

1300×650×450 |

75 |

3300×1700×1750 |

|

DM -CBF-110 |

1500×700×600 |

110 |

3500×1750×1900 |

|

DM -CBF-120 |

1500×800×600 |

120 |

3500×1850×1900 |

|

DM -CBF-150 |

1800×900×700 |

150 |

3800×1950×2000 |

|

DM -CBF-210 |

2100×1050×750 |

210 |

4120×2130×2110 |

|

DM -CBF-220 |

2300×1200×650 |

220 |

4320×2680×2010 |

|

DM -CBF-450 |

2500×1500×1500 |

450 |

4750×2980×2870 |