The brick moulds are made of 16# manganese steel. Besides the good raw material, precise line cutting technology and 900℃ carburizing heat treatment technology are all adopted in the process of the brick mould production

.

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fulang

-

Voltage:

-

220V/380V, adjustable

-

Dimension(L*W*H):

-

1800x1800x1500mm

-

Color:

-

Optional

-

Weight:

-

2600 kgs

-

Molding cycle:

-

15s

-

Pallet size:

-

No need pallet

-

Hydraulic pressure:

-

14Mpa

-

worker:

-

1-2

-

Certification:

-

CE,ISO

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

3500pcs/day

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fulang

-

Voltage:

-

220V/380V, adjustable

-

Dimension(L*W*H):

-

1800x1800x1500mm

-

Color:

-

Optional

-

Weight:

-

2600 kgs

-

Molding cycle:

-

15s

-

Pallet size:

-

No need pallet

-

Hydraulic pressure:

-

14Mpa

-

worker:

-

1-2

-

Certification:

-

CE,ISO

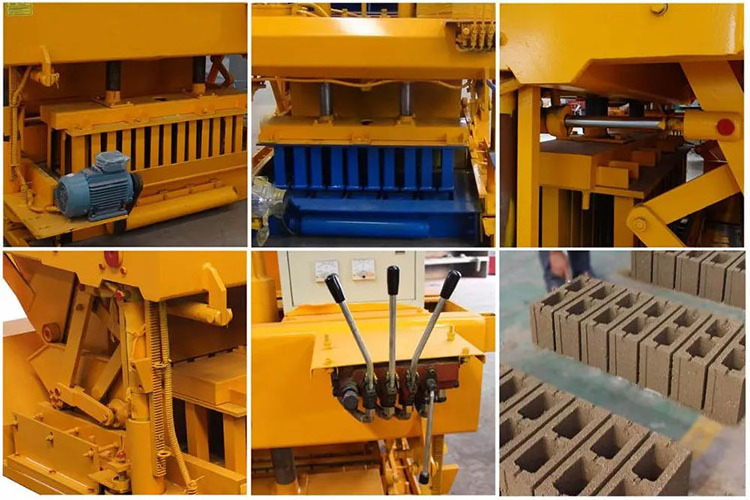

FL6-30 Manual Egg Laying Concrete Cement Brick Block Making Machine

■ Main advantage of this machine

1.Function

FL6-30 egg laying cement brick making machine can produce various different hollow bricks and solid bricks by changing moulds.

2.Technology

FL6-30 egg laying cement brick making machine adopts vibration technology to assure the better quality, larger density and higher strength of blocks.

3.Mould

The moulds adopt precise line cutting and carburizing treatment technology to prolong the mould life and increase the precision of the brick moulds. So the brick moulds have better performance and longer service time.

4.Capacity

FL6-30 is an automatic block making machine and shaping cycle is 30-35s. so the production efficiency is high with labor saving, it can produce 5760-12960 pieces blocks per day according block size

.

■ Main technology parameter and production capacity

|

Technical Parameters

|

|

|

|

|||

|

Dimension

|

2550*2200*1750mm

|

Moulding cycle

|

30-35s

|

|||

|

Rated pressure

|

7.5-14MPa

|

Machine power

|

11.2KW

|

|||

|

Vibration frequency

|

50-70HZ

|

Total weight

|

1500KG

|

|||

|

Production Capacity

|

|

|

|

|||

|

Size(L*W*H)

|

Pcs/Mould

|

Pcs/Hour

|

Pcs/8Hours

|

|||

|

400-200*200mm

|

6

|

720-1080

|

5760-8640

|

|||

|

400*150*200mm

|

7

|

840-1260

|

6720-10080

|

|||

|

400*120*200mm

|

9

|

1080-1620

|

8640-12960

|

|||

Brick mould

Easy operation

Control the movement of brick making machine,pull-push of mould and block forming by operating lever and pressing button of the control box.

FL6-30 egg laying concrete block making machine can produce various different hollow blocks by changing block mould. The following blocks are some common brick types. Also we can customize brick moulds for you based on your specific requirements.

JZC350 concrete mixer

Overall size 2766×2140×3000mm

Discharging capacity 350L

Loading capability 560L

Productivity 10-14m3/h

Maximum size of aggregate 60mm

Accuracy of water supply error ≤2%

Max Trailing speed 20km/h

Total power 11.55kw

Weight of the machine 1.4T

wheel loader(0.8T)

Overall size 4200x1470x2460mm

rated bucket capacity 0.25-0.5m3

Rated load 800kg

Maximum dump height 2350

Rated power 20kw

Rated speed 2200 r/min

Steering system type Articulated hydraulic steering

Min turning radius 3400mm

Weight of the machine 2.3T

Fulang Machine Machine is a Chinese dedicated machinery for construction blocks and panels.Our company offers complete production lines for premium building components such as the autoclaved sand-lime brick,autoclaved aerated concrete block,and autoclaved aerated concrete /autolaved concrete panel,various types of pressure vessels and block-making machines more than 60 varieties.By chosing FULANG,customers can enjoy professional benefits with our dedicated services for design,installation,layout planning,technology transfer,and production guidance.

Till now,about 1200 customers have visited our factory.Also we have engineers staying abroad to help you install machines and training your workers at your side.

☎ The FAQ

☛1.Q: What kind of payment terms do we accept?

A:T/T and L/C are common for us. Other ways are ok by negotiation.

☛2.Q:How about your Production time ?

A: Normally 20-25 days after your deposit.

☛3.Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year.

☛4.Q: Do you provide after-sale service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

☎ Our Service

★Pre-Sales

1.Perfect 7*24 hours inquiry and professional consulting services.

2.Visit our factory anytime.

★Sale

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

★After-Sales

1.Warranty period :1 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.