- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

10000*1200*1500MM

-

Weight:

-

300

-

Screw diameter (mm):

-

125, 125

-

Material:

-

PP/PE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

PP,PE,PET,PS,PCV

-

Motor:

-

copper

-

voltage:

-

220/240/380/415

-

Screw diameter:

-

125mm

-

Motor power:

-

22kw

-

Model:

-

YW-125

-

Max. Capacity:

-

120kg/h

Quick Details

-

Output (kg/h):

-

120 - 150 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YW

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

10000*1200*1500MM

-

Weight:

-

300

-

Screw diameter (mm):

-

125, 125

-

Material:

-

PP/PE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

PP,PE,PET,PS,PCV

-

Motor:

-

copper

-

voltage:

-

220/240/380/415

-

Screw diameter:

-

125mm

-

Motor power:

-

22kw

-

Model:

-

YW-125

-

Max. Capacity:

-

120kg/h

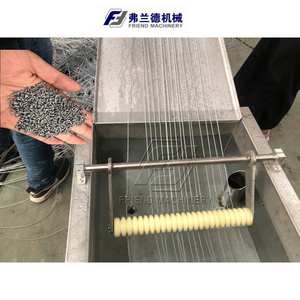

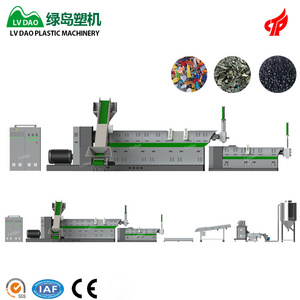

PE,PP , PS ,PET, PVC,EVA, ABS waste plastic recycling pelletizing machine

1.Introduction of:

Our factory can produce different type of plastic pellet ing machine, plastic crushing machine,

plastic drying machine , and plastic cooling tank ,water ring plastic pellet cutting machine. These

machines can granulate all kinds of waste plastics such as PE,PP , PS ,PET, PVC,EVA, ABS etc.

2.Necessay information need to be provided by customer:

Different plastic material should be processed by different machines , So please tell us

(1)What's your plastic material ?

(2) how many plastic do you want to to process per hour ?

then we will recommend you most suitable machine and quote you better price

3.Flow for different plastic

EPE plastic pelleting flow :

- 1. Crushing -----conveying-----pelleting-----water tank cooling----- cutting-----packing .

- 2. Crushing-----washing-----drying----- feeding------pelleting-----water tank cooling-----cutting-----packing .

PE /PP pelleting flow :

PE/PP film or bag -----Crushing -----washing-----conveying-----pelleting----- cooling-----cutting -----packing

PS plastic pelleting flow:

Crushing -----conveying-----pelleting-----water tank cooling----- cutting-----packing .

PET processing flow :

PET bottle -----conveying----labor removing-----conveying----- crushing-----

conveying-----kneading to remove the cap-----washing-----dewatering

-----packing.

4.Parameter of pellet machine

|

Model |

125 |

135 |

150 |

180 |

|

Capacity |

150kg/h |

200kg/h |

250kg/h |

350kg/h |

|

The diameter of first stage screw extruder |

125mm |

135mm |

150mm |

178mm |

|

The diameter of second stage screw extruder |

105mm |

125mm |

135mm |

150mm |

|

The motor power of first stage extruder |

30kw |

37kw |

45kw |

55kw |

|

The motor power of second stage extruder |

11kw |

15kw |

15kw |

22kw |

|

Mesh filter changer |

Electric mesh filter changer / Hydraulic mesh filter changer |

|||

|

Remarks |

We still have more models / support OEM |

|||